Can LED strip be cut and how to do it?

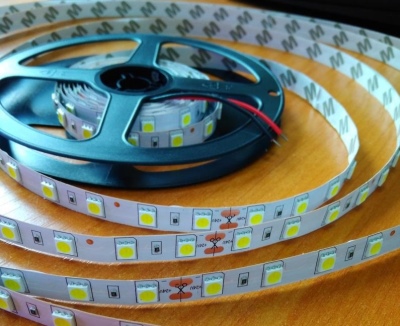

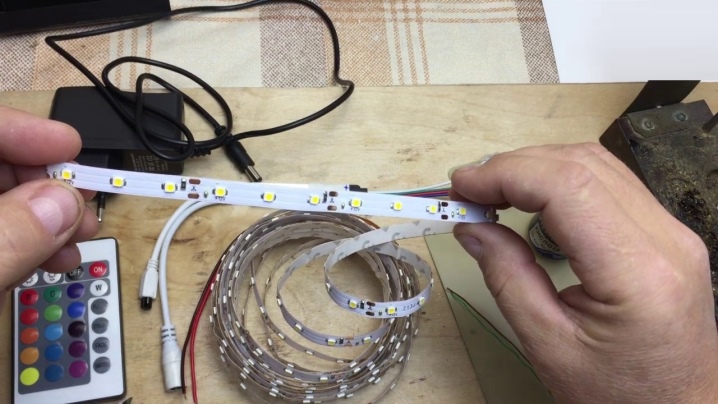

Not always a solid LED strip - for example, on a reel of 5 meters - turns out to be needed in a specific place. If we are talking, for example, about a car interior, then only one segment of 3-4 LEDs can be used in each backlighting place.

How do I cut different tapes?

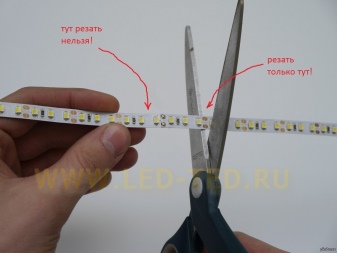

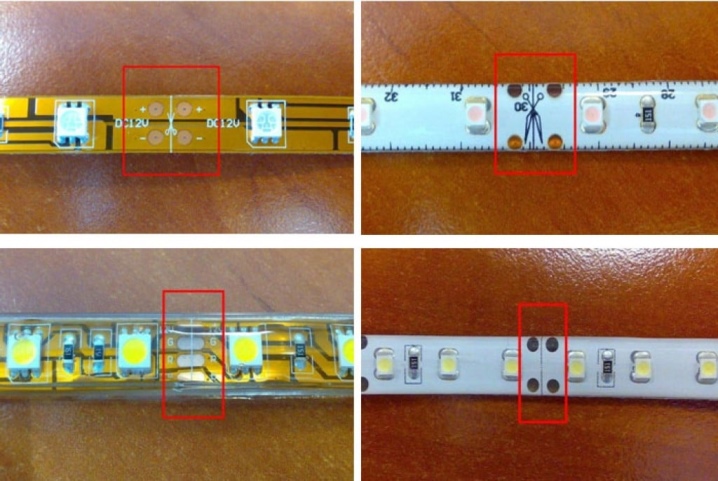

You can cut the LED strip only according to specific marks that are set (or not set) by a certain manufacturer... Not all of them mark the tape accordingly. Sometimes it is possible to determine the location of the cut only by carefully examining the topology of a kind of printed circuit board - a thin layer of textolite applied to a rubber or plastic substrate along with current-carrying tracks.

12V

For a 12-volt tape, the topology is arranged in such a way that the LEDs are connected in series - 3 in each group... This group, together with the series connection of the current-limiting resistor, forms a cluster or sector operating from 12 volts. It would be more correct to connect not 3, but 4 LEDs, since each of them is powered by 3 volts. If such an LED is connected to 4 volts, it will overheat - and after a few minutes it will burn out. To avoid this, the manufacturer includes a 20-30 ohm current limiting resistor. Accordingly, from 12-13.8 V, the entire assembly heats up noticeably to 60 degrees or more. And since it is more profitable for the manufacturer to turn on the ballast resistor instead of the 4th LED - while calculating so that after several hundred hours of continuous glow, the LEDs still degrade and fail due to significant heating, - the assembly should not be overloaded... It will be wiser do not exceed the supply voltage above 12 volts by choosing an appropriate AC adapter or stabilized power supply.

If we are talking about a higher voltage, then the power supply should be limited by current by installing lowering voltage conventional diodes, or by including an additional resistor, rheostat, or lengthening the wires.

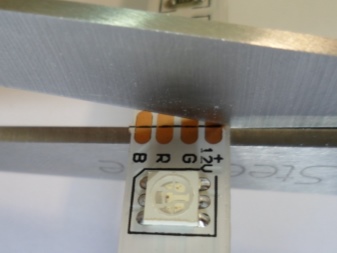

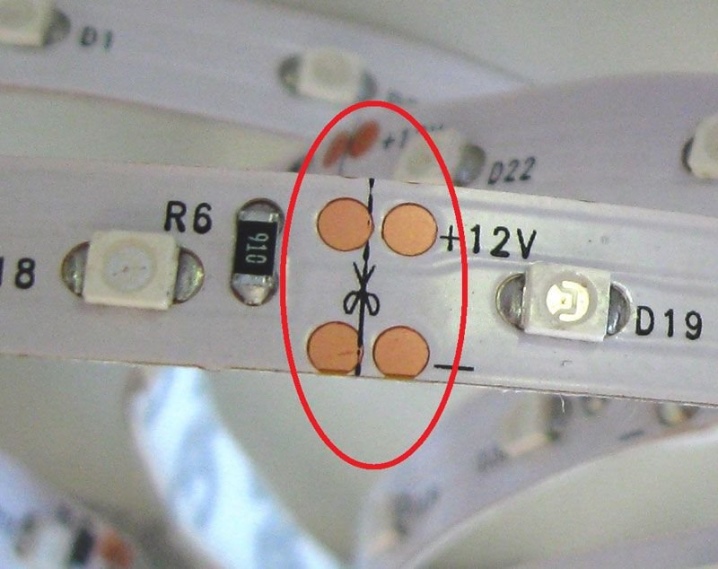

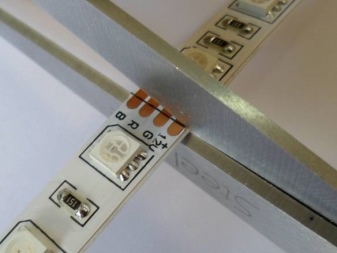

Cutting of the assembly is carried out at the scissor-shaped mark where the contacts "red", "blue", "green" and "mass" pass. It is not hard to guess that the three "colored" contacts are positive for each of the colored semiconductor crystals. In this case, the current-carrying paths go further, bypassing the LEDs and resistors soldered by the manufacturer. In LEDs that are not tricolor, or work as monochrome (red, yellow, green or blue separately), there are only contacts (and tracks) "plus" and "minus". 12 volt LED strips, for example, for red (used as a brake light and tail lights), contain 6 LEDs connected in series: the maximum supply voltage for each of them, which is not recommended to be exceeded, is 2.2, and not 2.7-3.3 volts. For 24 V tapes, the number of LEDs per sector is doubled.

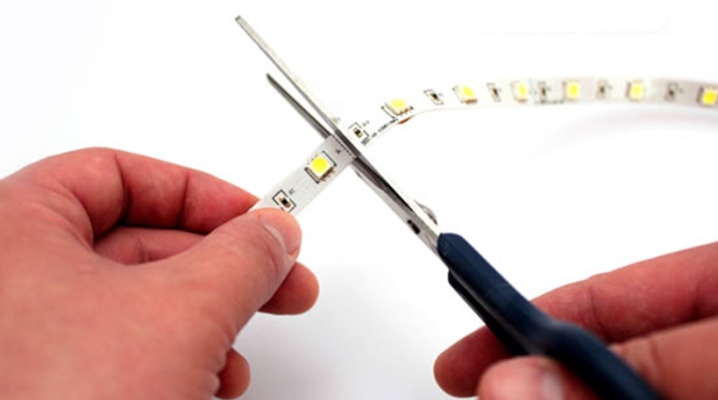

If there is no mark on the front side, the cutting line may be on the back... A thin strip is cut with scissors. You need to cut it exactly in the middle between the contacts: in case of accidental capture in either side, soldering the power wires will turn out to be an extremely difficult action.

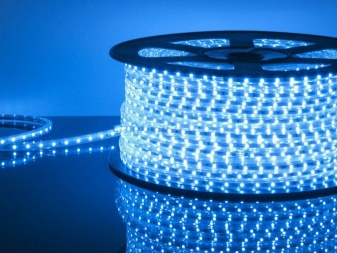

220 volt

In the case of a 220 volt tape, cutting off clusters is much more difficult. These are mainly the series of products SMD-3528/2835/3014/5050/5630 and several others, similar in power and operating current. They are cut by footage - 0.5, 1, 2 m. The number of LEDs is 30-120.Double LEDs are often used as white ones - 2 to 3 volts, connected in series in one light crystal. Accordingly, for uninterrupted operation, they require 30 pieces per segment. It is easy to calculate that 30 double LEDs (60 single - this is the conversion) are designed for a voltage of 180 volts. To make them glow as brightly as possible (3.3 volts on each LED), a voltage of about 200 volts is required. However, even here, manufacturers interested in the constant sale of LEDs make a deliberate mistake, including only 30 (and not 35-40, as it should be) double LEDs in the cluster. As a rectifier, a network diode bridge with a current-limiting resistor and a CHIP fuse can be installed on each cluster. Each piece is plugged directly into an outlet.

Needless to say, LEDs are forced to overheat. Some craftsmen rework the tapes, soldering additional groups of LEDs into it, or reworking the driver. As a result, the supply voltage at each light element (and the brightness of the glow) decreases slightly, which prolongs the life of the tape.

Tapes for 220 volts are also cut according to special marks. Important do not cut the driver (or contacts for an external driver). Their multiplicity remains at the level of 30-120 LEDs - dividing lines are indicated by the presence of a current-limiting assembly at the beginning of each composite cluster.

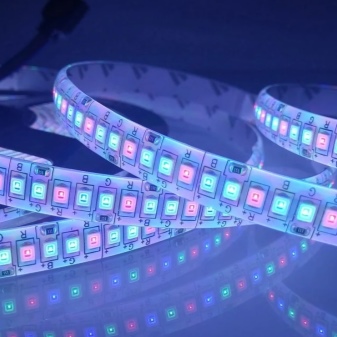

Color RGB

RGB color strips have four lanes - "common", "red", "green" and "blue"... A more advanced version - RGBW (white is added as the fourth LED) - contains 5 tracks in the ribbon topology (the 5th is the positive pin for the white LED). These assemblies are most commonly rated for 5 volts and have current limiting resistors for each color group. One cluster of RGBW tape contains 4 LEDs and 4 resistors (up to several tens of ohms). There are RGB tapes, in which two red, green and blue LEDs are connected in parallel - in series with a limiting resistor in groups. If we are talking about 12 volts, then the number of LEDs triples - six red, green and blue. In 24-volt strips, each color group is longer - it already contains 12 LEDs.

They are also cut according to marks (cut lines) and consist of clusters corresponding to their number.

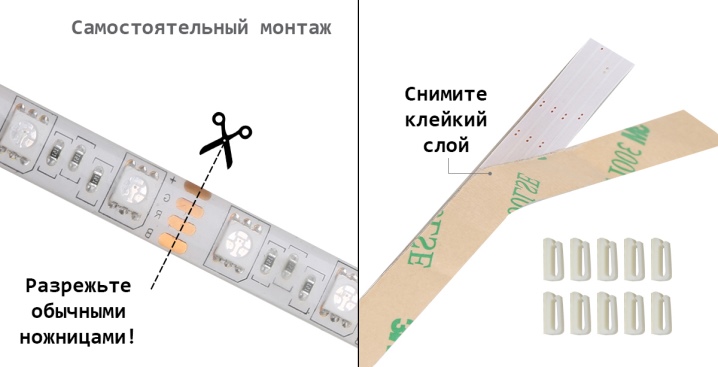

Trimming tape with waterproofing

There are no cut marks on the face of the print ribbon. But they can be found on the flip side. To cut at the point through which the cutting line passes, you must first remove the silicone. They are cut off with a clerical knife. After soldering the wires, the soldering contact points must be re-insulated.

Helpful hints

Anywhere the LED strip contains conductive tracks. Using an ultra-sharp blade (razor, scalpel) with a certain skill, the craftsmen clean the polymer layer to metal (copper), even when the tape is not cut quite correctly, but the LEDs and other parts are not damaged. It is better not to bring the situation to this point - if there are marks, cut along them. If the scissors (or knife) damaged the parts (components) themselves, then the failed segment will most likely not be restored.

Even when only one of the three LEDs is damaged, the utmost care and accuracy will be required so as not to damage the rest.

If one of the three LEDs in the 12-volt cluster is damaged, then the current limiting resistor will need to be replaced as well. Otherwise, the remaining LEDs, hitting too high a voltage, immediately burn out (the glow "subsides").

A sharp bend of some belts, even at the cut point, can lead to their breaking. Even when the LEDs are located on opposite sides of the point of a sharp bend, the tracks themselves can break - due to the fragility of the textolite or other composite material, of which the tape is made.It is forbidden to weave ribbons into knots, weave patterns from them - in addition to gaining the risk of being torn, the ribbon may lose part of the useful light flux due to the overlap of several LEDs with its own opaque substrate for light.

The comment was sent successfully.