Width of LED strips

LED light sources are a low-budget and simple solution designed for everyday use in the dark or for decorative lighting. The simplest LED flashlights almost from the first year of production gave way to light strips and LED filaments.

Selection criteria for LED strips

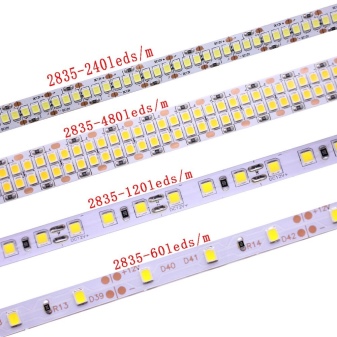

First of all, the light tape is chosen according to the power per linear meter - it is equal to 4.8-19.2 watts. The power consumption depends on the number of LEDs on each meter of the strip, as well as on the rating of each light element determined by the marking (model or series).

The second factor is the length of the diode tape in the coil - from 5 to 100 m. Cut-off points - they are accompanied by an identification mark resembling scissors - in tapes for supply voltages of 12 and 24 volts are located every few centimeters. 220 V tapes can only be cut every half a meter or meter - the serial connection of a large group of LEDs does not allow cutting light elements in small groups.

Finally, the width of the light ribbon depends on the number of colors of the emitted light. The LED strip is produced in the form of a high-tech flexible printed circuit board, the width of which ranges from a few millimeters to more than a centimeter. Typical variations are 3, 4, 5 and 6 mm light strip widths. Large values, used mainly for street and other external lighting, are 8, 10 and 10.2 millimeters.

Narrower - or wider - strips are also being developed: the former compete with LED filament, the latter with strip assemblies, approaching in performance to the light panels used in floodlights.

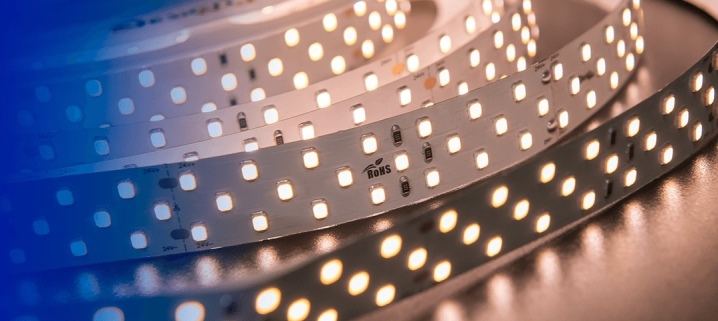

Tapes are available open (not protected from moisture) and closed. Closed tape - light elements - on a flexible mounting plate in a transparent polymer frame made by casting. The thickness of the open tape - from 2 mm, closed - up to a centimeter, together with the silicone coating. The closed tape can be used in rooms with high humidity, in the rain or immersed in water - the conditions are responsible for the moisture protection class from IP-65 to IP-69. Non-waterproof tapes are classified as IP-20 - IP-40.

Type and variety of LEDs

Having decided what width, thickness, length and power (light output) the tape is needed, it is not superfluous to clarify which LEDs were used in the production of light tape, the coil of which the user wishes to purchase.

So, SMD-3528 LEDs are characterized by a rather high fit, however, their heat-dissipating characteristics are noticeably worse than that of SMD-5050 light elements.

Due to the impaired heat dissipation, you should be extremely careful when powering the SMD-3528 LEDs: it is better to slightly lower the supply voltage, and with it the output light flux. If the heat does not have time to dissipate onto a metal or composite substrate, the LED will accumulate excess heat in a few minutes. Working practically overheated - the temperature of the LED reaches 42-75 degrees - the light crystal will burn out after a few hundred or a couple of thousand hours of continuous operation, since its so-called operating point of the current-voltage characteristic is violated, eventually going into the zone of thermal breakdown, which is unacceptable.

Features of light tape power supply

Some craftsmen advise to additionally include voltage-reducing rectifier diodes in the LED strip circuit. Either use an adjustable power supply or a driver in which the voltage (or current) is set using a standard resistor slider that acts as a kind of potentiometer. In this case, on a white LED, the voltage should be approximately 3 V (2.7-3.3 are allowed), on a color - red, yellow, blue or green - about 2 V (optimally 1.8-2.2). This applies to light strips of any width, power and number of LEDs per linear meter.

The comment was sent successfully.