Valve for washing machine: device and repair

Every housewife is interested in high-quality washing of linen, but this indicator directly depends not only on detergents, but also on the serviceability of the machine itself. Sometimes, during the operation of the unit, situations may arise when water is drawn back into the tank, which entails a shutdown of the device. The cause of such a malfunction, as a rule, is a malfunction of the water supply valve. You can fix such a breakdown with your own hands at home.

Types

The inlet water valve for the washing machine (antisiphon) is one of the important components of the unit, which reliably protects the water filling system. It is versatile, as it is suitable for any model of washing machine and has a small size. Today the following types of valves can be found on the market: non-separable, segment, cut-in and wall-mounted. Each of the above types is slightly different from each other.

- Unbreakable. It is usually chosen for soft water pipelines and can reliably serve up to 3 years.

- Wall-mounted... It is considered an excellent installation option if the space between the back of the washing machine and the wall is too narrow. The disadvantage of the product is its high cost.

- Mortise. Suitable when a direct discharge into the sewer system is required. It got its name from the special installation, which is performed by inserting.

- Segment (electromagnetic). It consists of two or three sections, each of which has its own separate valve; a special coil is responsible for its opening. If the valve design provides for two coils, then the water direction along the third channel is performed by simultaneously opening two sections.

Many manufacturers equip modern models of washing machines with a new generation AquaStop filter with a spring.

It reliably protects the room from flooding, which can occur if the hose of the unit is damaged. Compared to other types of valves, this one is able to withstand pressures up to 70 bar.

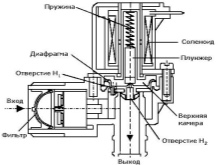

Principle of operation

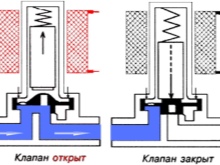

The valve for water in washing machines works simply because its design is primitive. This item can be installed both in the sewer pipe and in the drain hose or siphon. If a back pressure appears in the system, then the valve mechanism is triggered and it does not open, thereby protecting the unit from leakage. In this case, a rubber membrane and a spring act as a reliable shutter.

As for the solenoid valves, their principle of operation is slightly different compared to standard models.... As soon as the washing program starts, the control module immediately sends a signal to the valve. A voltage is applied to its coil, as a result, an electromagnetic field is created that opens the valve, and, therefore, water is supplied. As soon as the machine has reached the required water level, the voltage supply to the coil stops and the valve closes.

Possible problems

Sometimes, after washing, you may notice that the machine has been idle for a long time, and a lot of water has accumulated in its drum. The reason for this is usually the failure of the valve, which allows water to pass through.

If the unit is stored in a room with a subzero air temperature, then due to freezing of the liquid in it, the body of the device will begin to crack and more serious repairs will be needed.

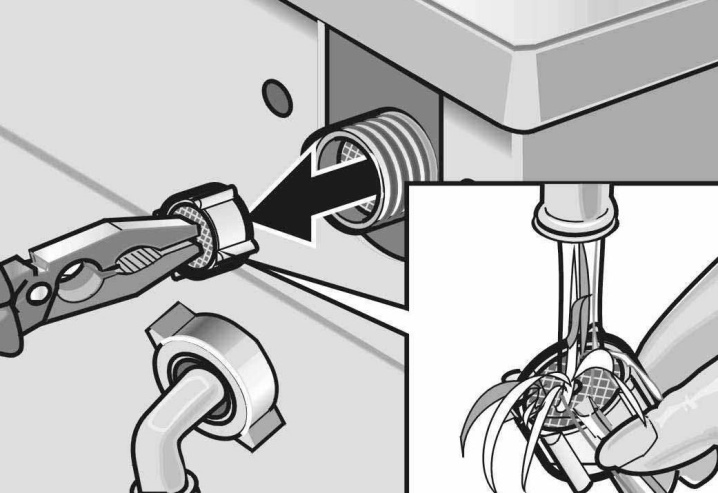

Valve failure can also be caused by clogging of the filter mesh. It is simple to eliminate such a malfunction - you first need to shut off the water, then dismantle the water supply hose and clean the mesh.

Much less often the cause of valve breakage is malfunction of the electromagnetic coils. If they are burnt out, the stem does not retract and, accordingly, no water is collected. Since most of the valves are of a non-separable type, they cannot be repaired. Replacement with a new valve is required.

Repair and replacement

You can check the operation of the water supply in the washing machine using a simple test. First, you need to remove the valve from the unit and connect a hose to it. If you connect a water hose, the valve should open, let water in and, after the power supply to the coils is cut off, close. In the absence of a set of water, the element should be replaced or repaired, for this it will have to be disassembled. As practice shows, most of the reasons for valve failure are associated with its clogging, therefore, experts recommend that you first check and clean the filters:

- first of all it is necessary disconnect the unit from the power supply and turn off the inlet valve;

- then the intake hose is disconnected from the body (so that water does not accidentally spill, you need to substitute the container);

- the hose is rinsed under running water and gently using pliers the filter mesh gets out, and it needs to be cleaned.

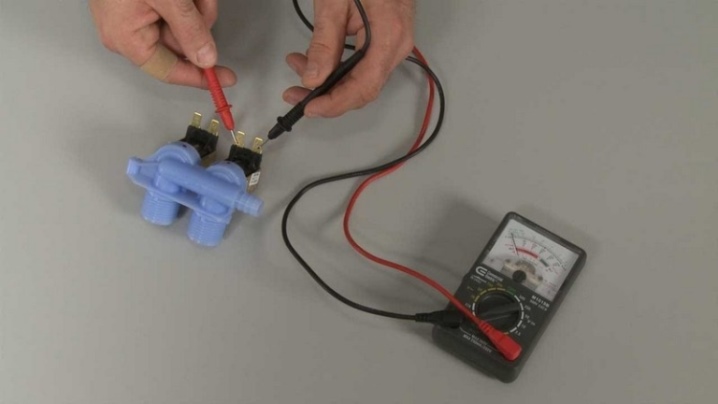

If the reason lies elsewhere, then you will have to open the back of the machine and check the operation of the coils. If, after applying current to them, the membrane does not open, then the coils are burned out. A special tester tool will also help to make sure that they are broken. - multimeter... It is set in the resistance measurement mode and the probes are applied to the coils - if they are in working condition, then an indicator from 3 to 4 kΩ will appear on the display. After that, it remains only to connect the pump and check the subsequent operation of the valve.

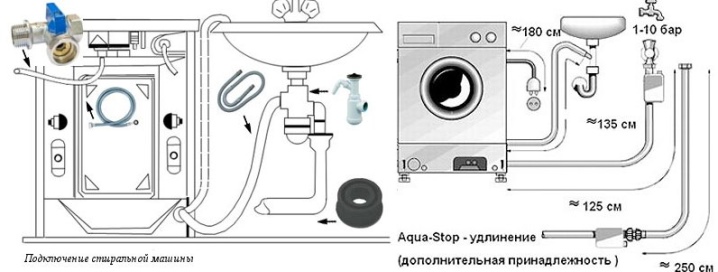

In the event that the valve does not work again, then you need to start replacing it. Any water valve is installed according to the same principle, the only thing is that when you replace the element yourself at home it is necessary to take into account its design features. The valve has 2 outlets of different diameters, the end of one of which is connected to the drain hose of the washing machine, and the other to the sewer. After the valve is installed, all joints should be sealed.

If the unit is correctly connected to the water supply and sewerage system, taking into account the height standards, then it is not necessary to additionally install an anti-siphon and the valve replacement is considered complete.

As for the repair of the water solenoid valve, this cannot be done., especially if it is broken inside or the coil is burnt out. In this case, the easiest way is to replace it with a new element. They do it like this:

- disconnect the washing machine from the power supply, shut off the water supply, remove the side or rear panel of the unit and unscrew the water hose;

- then remove all fasteners and carefully remove the broken valve, installing a new one instead;

- the replacement is completed by assembling the structure in the reverse order (so as not to confuse the placement of the hose and wires, take a photo before disconnecting them) and checking the operation of the system.

If everything is done correctly, the washing machine will start working. After starting it, it is imperative to check how water enters the tank and whether the valve mechanism is stopped in time.

For replacement and disassembly of the washing machine valve, see below.

The comment was sent successfully.