All About Lathe Centers

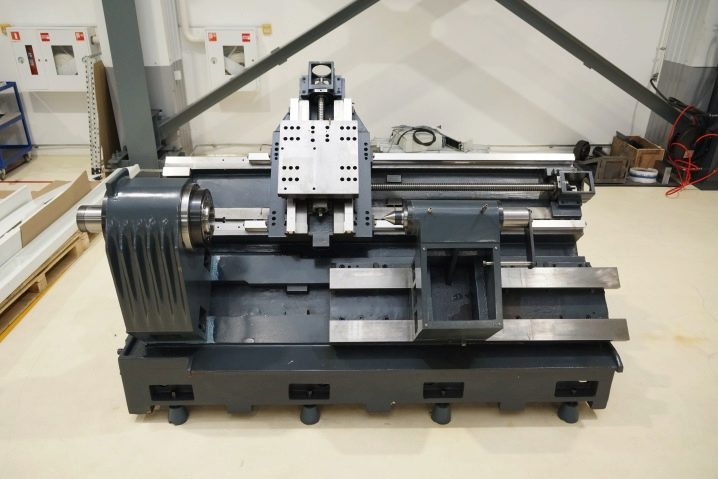

The lathe is the equipment demanded in the industry. The fixation of the elements on the installation is carried out using a special component called a turning center. The special design allows you to securely fix the part on the working surface of the machine, and organize efficient work at high speeds.

Peculiarities

The turning center is a strong and durable component used to fix workpieces into a tapered groove. Element construction includes:

- directly the center;

- ball or needle bearings;

- stops made of durable materials;

- conical shank.

The latter is responsible for mounting the center in a quill. In some machines, the center comes complete with a built-in device for determining the axial forces occurring during operation. The part is in demand when fixing large and heavy parts. The presence of the center ensures reliable fastening of the workpiece, preventing it from moving. It is especially important if you plan to form planing on large sections.

Turning on a lathe is a process that is impossible without fixing the workpiece in a special chuck. Fixing the product to the ends of the lathe is possible in the following cases.

- The lathe provides for the adjustment of the number of revolutions made... An increase in speed leads to the transfer of additional loads to the part, which reduces the accuracy with which machining takes place. Therefore, it becomes necessary to use the center. Otherwise, there is a high probability of a large error in processing.

- Workpieces with a large weight and medium length require secure fixation using a tailstock. Otherwise, the product will quickly deform under its own weight, and metal cutting will be ineffective.

- When you change two important parameters of the equipment - the speed and the turning mode of the spindle - the likelihood of a strong cross-type feed with subsequent unpleasant rollback increases. If this moment is not taken into account, and if you do not take care of additional fixation of the workpiece in a timely manner, the cutting accuracy will decrease.

Pivot centers solve the problem of fixing the workpiece and prevent any deviations during cutting and planing. The pluses of the element include a number of factors.

- Versatility... The use of a nozzle allows processing of different sizes and configurations, but it is worth purchasing a nozzle for this.

- High performance... The centers are more reliable than standard clamps and have a long service life.

- Efficient work even under excessive loads... The part is able to withstand increased loads, many times higher than those that conventional clamps can withstand.

- The only drawback is the radial runout of the part. The problem can be solved by using reverse tooling or reducing equipment speeds during finishing.

Fixing the workpiece with a turning center is an effective way to obtain a high quality product. You can install the mount yourself without the involvement of specialists. The procedure will not take much time, while making the workpiece motionless.

Views

Manufacturers produce different types of turning centers, each of which is suitable for performing specific tasks or equipping specific models. All turning centers according to GOSTs can be divided into two types.

-

Thrust parts. In this case, the element has a shank and a tip of almost the same dimensions. For the production of parts, hardened steel or high-quality metal is used, regulated by GOST 13214-79.

- Fungal parts... A variant with slight differences from the previously named one. As stated in GOST 8742-75, the element should have an increased diameter and a truncated working cone. Fungal centers are additionally divided into fasteners equipped with a centered shaft or a special attachment. The advantages of such parts are the possibility of using a special device where bodies with hollow end holes are attached. This solution enables efficient processing.

To achieve optimal conditions for turning the workpiece with the unfavorable effect of centrifugal force, which is formed in the process, it will be possible with the help of a solid center, whose design also includes a bearing. The equipment can be varied, but the principle of operation, regardless of the type, is practically the same.

Features of operation

Before starting to work with the equipment, the turner should consider several recommendations for using centers and lathes with them.

- Taking into account the runout error. Deviations sometimes occur as a result of wear on the bearings or center tip, resulting in poor cutting or planing. Often the reason for this phenomenon is insufficiently rigid fixation of the element. Experienced craftsmen advise replacing the equipment with a more reliable or new one.

- Taking into account the location of the axes that pass through the center and the spindle. They must match, otherwise there is a high probability of getting errors during operation.

- Making allowances for finishing material. A mandatory procedure when it comes to the point of parts of an increased accuracy class. In this case, by means of the clamp, it turns out to ensure reliable fixation of the workpiece so that it does not budge. But at the same time, the rotation of the product must be free.

- Center beat accounting... The problem is the subsequent runout of the part about the axis. Failure to do so will result in the impossibility of machining the part on another machine due to the risk of axes mismatch. Therefore, if excessive runout is found, the tip should be replaced as soon as possible, or sanded with a tool.

Only after a thorough inspection of the workpiece cutting equipment and the rotating center can the metal processing work begin. In addition, it is worth noting that turning at high speeds significantly reduces the service life of the center tip and breaks the centering hole. To prevent the need for premature replacement, it is recommended that the handpiece be treated with special compounds such as lubricants.

For centers for lathes, see the following video.

The comment was sent successfully.