Varieties and selection of desktop lathes

Almost every production process is associated with the need to use special equipment - lathes. However, it is not always possible to organize the installation of dimensional devices. In this case, craftsmen give preference to table-top lathes, the features and types of which are worth considering in more detail.

Description and purpose

A desktop lathe of Russian or foreign production is an ideal solution for craftsmen who want to work at home. The installation is suitable for placement even in small spaces:

- garages;

- workshops;

- offices.

The unique equipment has a wide functionality that is in no way inferior to factory units. The only difference is the more compact size. Thus, the mini-machine is an exact, but reduced copy of the overall installation. It is suitable for processing small workpieces of various shapes and sizes. Also, a small machine makes it possible:

- drilling;

- turning grooves;

- thread formation;

- trimming the ends;

- leveling the surface.

The machine is easy to use, which has been confirmed more than once by the reviews of satisfied craftsmen. To organize safe and fast work, the equipment is placed on a special stand or a stable table. For fixing, fasteners are additionally used if you do not want the unit to move during operation. Most of the bench-top machines are in demand in small workshops, lathes and other premises. Recently, however, such equipment has also been popular in schools, factories and other large facilities.

Species overview

Desktop lathes are in demand among owners of small workshops and those who like to work in the garage. The advantages of such equipment include:

- light weight;

- compact size;

- the possibility of installation in rooms of a small area;

- inexpensive price;

- work from a voltage of 220 V;

- adaptation for connection to a three-phase network;

- long service life with a competent approach to operation;

- economical energy consumption.

The desktop setup is easy to learn, so the user can get up and running quickly. Even for a beginner, processing materials on a desktop machine will seem simple.

Manufacturers produce a wide range of compact models, regularly updating and modernizing catalogs. It is worth considering the main classifications of lathes.

By modification type

Depending on the type of fastening, precision machines are distinguished with the following parts.

- Collet. With its help, it is possible to fix elements of small thickness.

- Drill chuck. They are equipped with machines where fastening of parts of different shapes and sizes is required.

- Flatbed. Option for processing large and complex elements. However, when using such a chuck, it becomes more difficult to center the part about the axis.

Manufacturers produce machines both with a separate type of chuck and universal models.

By type of incisors

Table lathes are equipped with different cutters. Classification implies division into the following options.

- Finishing. The equipment is often used for thorough and high-quality finishing of parts.

- Medium. With the help of such installations, it will be possible to quickly process the surface of the element, but at the same time the quality and accuracy will be lower.

- Rough. Cutters for work from scratch where rough material is required.

The choice of machines is determined by the needs of the user, as well as his financial capabilities and the nuances of the room.

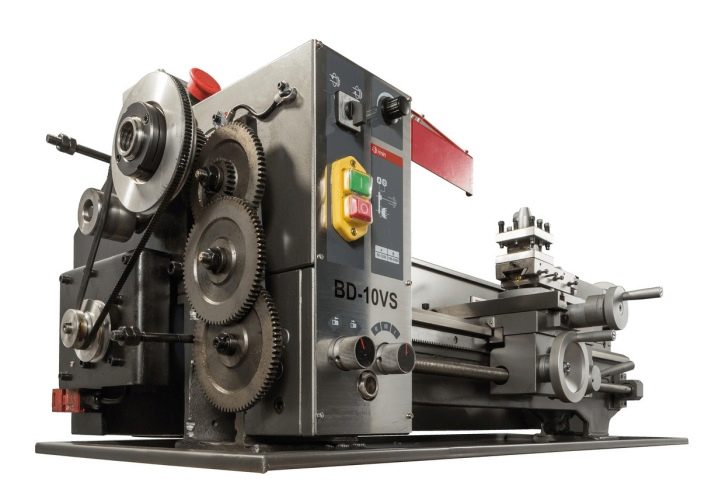

Manufacturers

Today, the production equipment market is represented by a wide range of various machine tools, including bench-top ones. Among the huge variety of companies, it is worth highlighting two whose equipment is considered the most in demand.

- "Anchor". Russian brand that produces high quality machine tools. The manufacturer's equipment is distinguished by increased reliability indicators, demonstrates excellent performance and a long service life.

- Jet. A manufacturer from America, which is engaged in the production of machines that meet modern requirements. The company cares about the quality of its products, so the user can be sure of buying a safe and reliable unit.

There are other companies that build benchtop lathes as well. However, the listed manufacturers are considered the best on the market.

Rigging

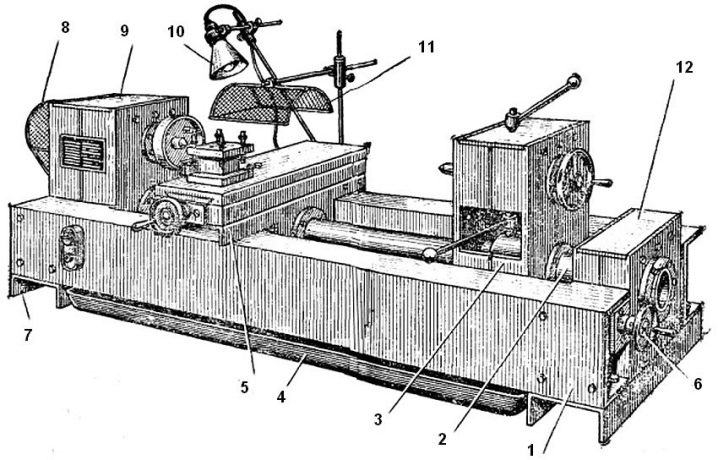

The main structural elements will be as follows.

- Stanina. The main part to which other parts are attached. Represents the main assembly, which then fixes the device on the table. The frame is predominantly made of cast iron to ensure that the parts can withstand heavy loads.

- Caliper. An element for fastening drills, cutters and other tools with which the material is processed. Provides reliable fixation of products and is responsible for timely movement of the drill in the required direction. The caliper moves due to the stroke shaft and the transmission element.

- Spindle. An equally important part of the machine is in the form of a cylinder, on the characteristics of which the functionality and performance of the device depend. It is included in the work due to the energy that it receives from the engine.

- Center for holding long parts during turning. It has the shape of an ordinary stand, which is set in motion by a special lever. When the element reaches the required position, it stops.

- Drive unit. The belt is mainly used, since this option is considered the most convenient and reliable. The mechanism stops if the workpiece jams for some reason.

The smallest models have only one place for the cutter in the holder. Therefore, the craftsmen have to constantly reinstall the part and adjust the height before starting work.

Some models are equipped with additional equipment that can improve the potential of the device and increase productivity. If necessary, the user can independently purchase slotting accessories.

Selection Tips

Buying a table lathe is a complex process that needs to be approached carefully. If you are not careful about the choice, then it will be difficult to use the purchased device or it will not work at all. You need to take into account several nuances.

- Purpose of the device. For example, craftsmen often purchase models with advanced functionality, where the equipment is able to grind parts, grind material.

- The size of the suggested parts. Here you should pay attention to the diameter, length and other technical characteristics.

- Accuracy of operations. An equally important question, on which the cost of a future purchase depends.

- Scale of work and frequency of use. You shouldn't buy an expensive machine if it will only be used once a year.

When you think over all of the above, in your thoughts it will be possible to collect an approximate image of the desired model. Only after that you can go to the store for a purchase. In this case, during the hike, the following parameters should be taken into account.

- The way of mounting the machine and the weight of the structure. Craftsmen believe that the heavier the equipment, the higher the quality will be. But in reality this is not the case, so it is better to immediately take into account the place where the machine will stand. It is better to give preference to a compact and lightweight model, which, if necessary, can be easily transferred.

- Working voltage. When using the device at home, keep in mind that the mains voltage is 220 V, which is ideal for small installations. Larger models of desktop machines may require a voltage of 380 V, and then it will be necessary to urgently change the wiring or model.

- Power. In this case, there is a direct relationship, and the higher the power, the better the processing of the material will be. However, for home use, machines with a power of up to 400 watts are quite suitable.

- Shaft and spindle rotation speed. It is also worth paying attention to the possibility of adjusting the speed modes.

- Division value, which is located on the dial scale. The higher the indicator, the lower the accuracy of the instrument.

- Distance between headstock. Parameter for determining the maximum length of the material that will be put into processing.

Additionally, the masters recommend clarifying the diameter of the quill, since vibration and noise depend on it.

Operating rules

The trouble-free operation of bench-top lathes and a long service life are ensured by competent operation, which is impossible without the creation and observance of optimal working conditions. Here are the basic rules and guidelines.

- In the workshop where the machine is located, the temperature must be maintained no higher than +35 degrees. But parameters below +1 should not be allowed. If the unit was previously located in a cold room or outside a building, where the temperature is below zero, it must first be warmed up for 8 hours.

- The humidity indicator in the room where the machine is located should not be higher than 80%.

- With regular operation, it is necessary to change the oil in the box in a timely manner, as well as to inspect the engine for the presence of various contaminants. If any have been identified, they must be removed immediately.

- At the end of the work, the surface of the machine should be cleaned from construction debris in the form of shavings and dust.

During the processing of the material, it is also worth monitoring the observance of safety measures.

The rules here are:

- work should be carried out in personal protective equipment: glasses and clothing that fits snugly to the body;

- all foreign objects must be removed from the working area;

- the control and switch handle must be located outside the hazardous areas of the installation;

- before starting the equipment, it is required to carry out mandatory control of the reliability of fasteners and the degree of fixation of the part;

- during operation, the coolant level must be monitored to prevent overheating of the equipment.

Violation of at least one of the listed rules can cause unpleasant consequences in the form of injured hands and eyes. Neglecting operation and safety can lead to serious injury.

The benchtop lathe is the first and most popular machine tool. A plus of small-sized models lies in their size, which allows you to install machines in almost any room.

The comment was sent successfully.