All About Lathe Chucks

The rapid development of the metalworking industry would have been impossible without the improvement of machine tools. They determine the grinding speed, shape and quality.

The lathe chuck holds the workpiece firmly and provides the required clamping force and centering accuracy. This article discusses the basic nuances of choice.

Peculiarities

This product is used on general and special purpose machines to clamp the workpiece to the spindle. This provides a firm hold and high clamping force at high torque.

Views

A huge number of chucks for lathes are presented on the modern market: driver, pneumatic, diaphragm, hydraulic. They are all classified according to the following four criteria.

By the design of the clamping mechanism

In accordance with these parameters, lathe chucks are divided into several types.

-

Guide chuck. Such products are the simplest and are used for processing the center. If the flanks need to be sharpened, choose the options with notches or pins.

-

Self-centering spiral.

-

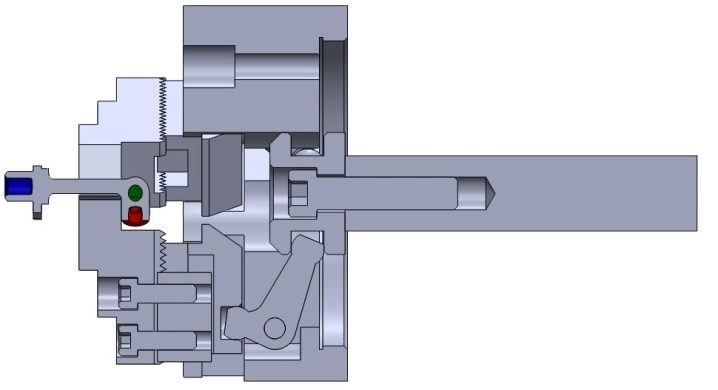

Lever... This type is characterized by a hydraulically driven connecting rod. The product boasts an increased demand in small industries.

-

Wedge-shaped... It resembles a lever, but has a higher centering accuracy.

-

Collet... Such an assembly can fix samples only in the form of rods of small diameter. Despite its reduced versatility, it is popular for its low radial runout, which has a positive effect on quality.

-

Drilling - to connect the drill to the machine.

-

Shrink fit chuck... It is used on the same machines as the collet but requires shrink fit.

-

An alternative to the collet is the hydraulic pneumatic chuck. Lathe chucks grip the tool under the pressure of the working fluid, so less force is needed to securely grip the tool.

Let's take a closer look at the structure and features of some of the popular varieties.

Collet

An important role is played by the metal sleeve, divided into three, four or six parts. Their number determines the maximum diameter of the item to be fixed.

By design, they can be divided into two types: feed collets and clamping collets. They consist of a hardened steel bushing with three non-perforated cutouts, the ends of which are pressed together to form a petal. The ejector collets are spring loaded and vary from model to model.

As the collet moves in the chuck, the groove narrows, the grip of the retainer and the workpiece increases.

For this reason, this type of chuck is often used for reworking already machined workpieces. If the type of workpiece does not match the shape of the collet, craftsmen resort to using replaceable inserts.

Lever

Central to the design of this device is a two-armed lever that drives the holders and clamps. Each of them has a different number of cams. This feature allows you to machine parts with complex geometries. The chuck on lathes takes longer for auxiliary work, which reduces productivity.It is nevertheless a suitable tool for make-to-order production in small factories.

This type of machine can be adjusted with a wrench (which moves the cams at the same time)... The position of each piece can also be adjusted independently.

After the workpiece is clamped, a lever-type product is usually chosen for roughing, since the slightest play can affect the shape of the future part.

Wedge

The wedge chuck for lathes is a more advanced version of the lever-type design. Several independent drives are used to adjust the position of the clamps. As a result, workpieces with complex geometries can be clamped and rotated in any direction. Among other things:

-

you can process products with a small error and precise shapes;

-

a uniform force is applied to each cam;

-

high-quality fixation at high speeds.

However, the complexity of the setup and the setup time before work are significantly increased. In many cases, lathe chucks have special clamping models adapted to work with CNC devices.

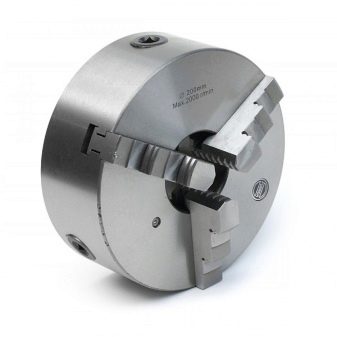

By the number of cams

The products described below are in greatest demand.

-

Two-cam... These chucks have two cylinders, on one side, with a screw between the cams or a mechanical transmission. If the gap is offset towards the workpiece, the center axis will also be offset.

-

Three-cam... They are driven by a gear drive and allow quick fixing of parts without time-consuming readjustments. Centering is done using tapered or cylindrical shoulders.

-

Four-cam... It is fastened with screws and is completely autonomous, their axes are in the plane of the disk. This type of lathe chuck requires careful centering.

-

Six-cam... These cartridges have a low crushing force, and the compression force is evenly distributed. There are two types of cams: integral and assembled cams. They are not very popular, and you can buy them only by pre-ordering.

By clamp type

The chuck jaw is divided into a forward cam and a reverse cam. This has almost no significant effect on performance.

This is perhaps the most popular design. The mechanism works by moving the cam and clamp using a two-armed lever.

Accuracy class

There are 4 classes of accuracy in total:

-

h - normal accuracy;

-

n - increased;

-

b - high;

-

a - especially high accuracy.

Depending on the application, the material of the chuck body can be selected:

-

cast iron ≥ sc30;

-

steel ≥ 500 MPa;

-

non-ferrous metals.

Dimensions (edit)

There are a total of 10 standard lathe chuck sizes: 8, 10, 12, 16, 20, 25, 31.5, 40, 50 and 63 cm.

Manufacturers overview

In the modern market, German Rohm and polish Bison-Bial, which also have factories for the production of technical equipment, tools and machine tools. Although they are very expensive, producing anything without turning chucks is now simply unthinkable.

And also the cartridges of the Belarusian manufacturer "Belmash" are very popular in the CIS.

What to consider when choosing?

Improper design can lead to an increase in the number of defective products and machine breakdowns. According to GOST, the following points should be taken into account when connecting.

-

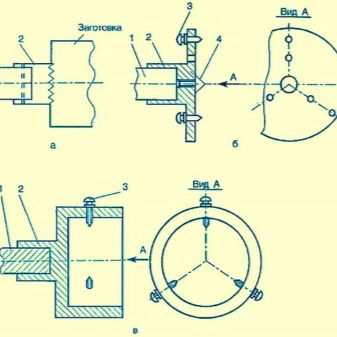

Mounting type on the spindle shaft. Centering straps, flanges, cam clamps and swivel washers can be used for fastening.

-

There is a frequency limit... Consider the maximum speed at which the lathe chuck will work.

-

Number of jaws, type of jaw (surface-mounted or combined), hardness and method of clamping, type of movement - all this determines the performance of the clamp and the time required for its readjustment.

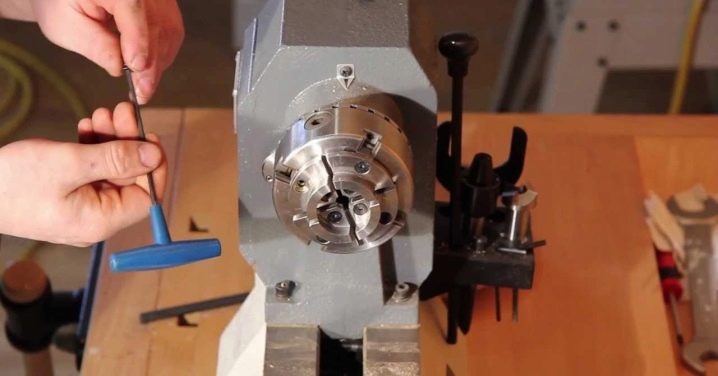

How to do it yourself?

Think in advance how the product will be fixed on the machine, and, if necessary, make or buy a threaded bushing. Then you can continue.

-

On the existing plate, mark a circle and two axes passing through its center and intersecting at an angle of 90 degrees.

-

Use a jigsaw to cut out the bezel at the mark, and sand it well.

-

Along the resulting axis, grooves are cut a few centimeters from the center and two to three centimeters from the edge.

-

Saw the corner into four equal pieces and drill a hole in each side with the same size drill.

-

Thread an M8 thread in the second corner strip and screw in the bolt.

-

Fit the threaded bushing for shaft mounting.

-

Secure the bracket to the bezel with bolts and washers.

-

The last step is to install the chuck on the lathe.

To secure the workpiece in this homemade chuck, the angle is moved and fixed by tightening the nut, and finally the workpiece is clamped with a screw screwed into the thread.

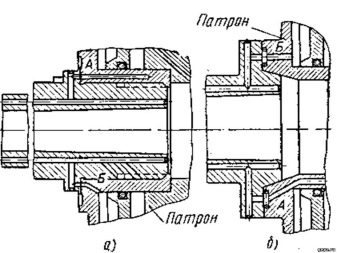

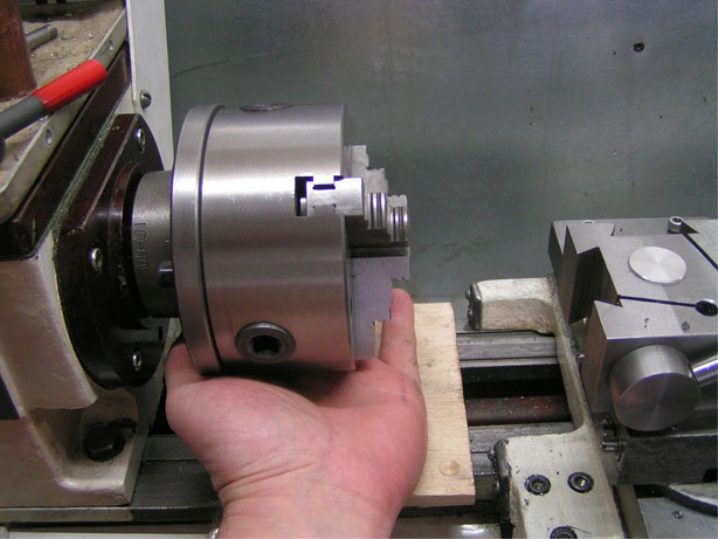

How to install and remove correctly?

The machine can be equipped with threaded or flanged chucks, it all depends on its size. The first type can be used on mini machines. The threaded chuck is not very heavy so assembly is not a problem, just align the threaded parts and screw them together. This can be done by one person without the use of tools.

The flanged version of the chuck can weigh more than 20 kg. The most popular type is the swivel washer mounted under the spindle.

Installation is carried out in several stages.

-

First, check the condition of the chuck and spindle and rectify any faults. The spindle runout should be no more than 3 microns.

-

The machine is put at neutral speed.... Next, the cartridge is installed on the mounting base. Now you need to center the chuck.

-

Install the caliper to the spindle at a distance of about 1 cm, aligning the studs with the holes in the flange. Then the tailstock is fed into the chuck, the guide runs along the entire length between the cams, then it is clamped.

-

In the next step, the chuck is pushed onto the spindle (the pin is inserted into the hole of the flange) and the quill is extended - movable headstock sleeve.

-

Then the cam is released, the tailstock retracts and the nuts are tightened. At the end of the work, check the end runout.

Next, we will consider how to remove the chuck of an automatic woodworking machine.

-

After removing the cam in advance, set the guide as far forward as possible relative to the chuck. Secure the tailstock.

-

Then the nuts holding the chuck in place are removed one by one. To do this, it is necessary to set the gear lever to the minimum rotation in order to prevent changing the position of the chuck.

-

After loosening the first nut turn the lever to high speed, and turn the chuck to the desired position.

-

Pull in the quill, and slowly detach the chuck from the spindle flange.

-

If the cartridge weighs quite a lot, it must be placed on some kind of support, then release the cam and remove the guide from its seat. That's all, the work is over.

Compliance with the rules for setting up and operating machines guarantees the quality of the results of processing workpieces, and ensures long-term trouble-free operation of the machine.

Operating tips

Correct use of the lathe includes the following.

-

Regular cleaning equipment and regular chip removal will help minimize downtime, breakdowns and rejects during turning. If maintenance is not carried out on a regular basis, equipment breakdowns can increase dramatically, durability can be reduced, and production costs can increase.

-

To avoid equipment failure, you should regularly check the condition of the cutting edges and backs of the working tools, promptly sharpen or replace blunt tools.

-

All the components you needsuch as oil, coolant, tools, lathe accessories and fasteners, must be of the appropriate quality and of the specified brand.

-

Replacement of defective parts and tools, elimination of simple malfunctions.

The comment was sent successfully.