Lathes for wood

Wood lathes are one of the most common types of equipment in workshops and industrial enterprises. The device for a home workshop and the specifics of its work deserve attention. And also it is worth understanding the differences between industrial, table-top machines and school apparatus for crafts.

Types and characteristics

Desktop

Usually, such a wood lathe is used not in professional industries, but at home. Nevertheless, such equipment allows you to perform quite serious work. With its help, piece and small-scale products for household needs are often produced. Sometimes such equipment is purchased even for large woodworking industries - more precisely, for their subsidiary and auxiliary sites. Desktop hand-held devices are universal and are often installed in baguette shops. They are used to receive:

- legs;

- boxes;

- coasters;

- dishes;

- racks and the like.

School

Such devices are designed for fairly simple operations with wood raw materials. They usually cannot boast of a large caliber, operation at high speeds or equipment with advanced automatic control systems.

But on the other hand, such models allow you to demonstrate the manufacture of basic types of products and achieve real beauty. Household utensils and souvenirs are made without any problems.

Having worked the skills on a school lathe, it will be easier to master advanced CNC models in the future.

Industrial

Among them there are both small and very large models. Much depends primarily on the required performance and speed of rotation of the working parts. The milling versions allow the production of both structural and decorative items. Panel saws are used to prepare blocks, then used in furniture and other industries. The power of an electric motor of 0.35 kW is usually not enough in industry; at least 1.5 kW is needed there.

In addition to this point, other technical parameters must be taken into account:

- length, width and height;

- the approximate size of the parts to be processed;

- reverse;

- spindle torsion speed, the ability to adjust it;

- types of processed wood;

- performance;

- power consumption;

- life time;

- mass.

Device and principle of operation

The main parts of any lathe are:

- bed (main support);

- tailstock and headstock;

- an electric motor, thanks to which knives or other rotating tools work;

- tooling parts that are attached to the main units, most often to the bed.

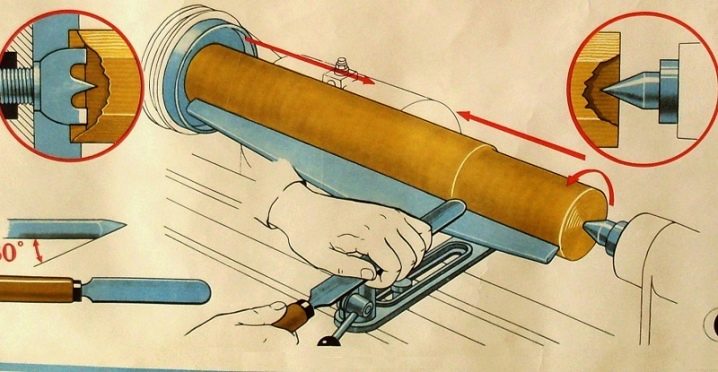

The main support is made of cast iron or steel alloy. It is always monolithic and guarantees minimal vibration of the apparatus. The role of the front headstock is manifold. It is designed for fastening the workpiece. The same unit also transmits the torque through the spindle; special belts are used for its broadcast.

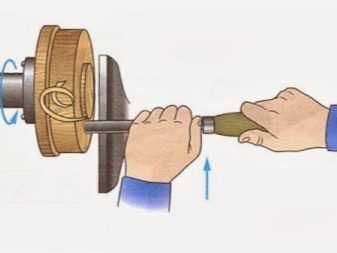

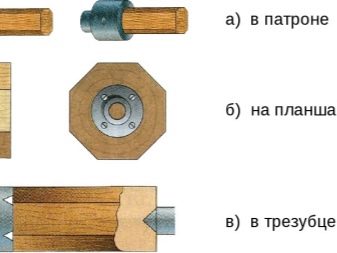

The standard scheme involves holding the workpieces in the spindles using a driver chuck. If you need to process a blank, damp its vibration, use a tailstock with a cartridge inserted into it. The faceplate is also important, with the help of which the blank is attached in the process of turning the ends. In other operations, a center-to-center fastening is used, and the part must be located exactly between the centers, otherwise the runout will go too strong.A handcuff is a knot that acts as an additional support for cutting devices; it is usually executed in the form of the letter T.

The role of a stop in a woodworking machine is to clamp and feed the bars. The positioning accuracy of the workpiece will be maintained very efficiently. Sometimes they do such a detail with their own hands, using a channel or a flat board.

The design, known as the ball point, lives up to its name. With its help, you can grind out spherical blanks. Balloons are also sometimes made with their own hands.

A trident is also useful. If it is placed on the machine, it will prevent the workpiece from turning axially during chip removal. Visually, such an element looks like a crown with a sharp serrated edge. There may be a sharp spike in the middle, but this is not at all necessary.

Wood turning is unthinkable without various cutters. Reyer is used at the initial stage of parts preparation. It is an elongated steel blade in the shape of a semicircle. At the final stage (when fine-tuning), a meisel is needed - a detail that looks more like a boot knife. There are also shaped cutters: rings, chisels, combs, hooks and triangles, the choice of which is determined by the target shape of the workpiece.

Additionally can be applied:

- knurling;

- lunettes;

- caliper holders;

- rollers;

- cartridges.

Wood processing on a lathe is carried out using a cutting unit. It is fed to the right place either automatically or manually. Before starting processing, the required part is fixed in special clamps. By changing the design of the cutter, it is possible to produce surfaces of any kind.

To make the work go well, set the optimal speed of turning the workpiece, and the feed angles; the pressing force is also normalized.

Appointment

You can also simply cut a piece of plywood or board on a lathe. But its capabilities are much wider than experienced craftsmen use.... When processing wood, it is even possible to carve a vase. For example, walnut, with inserted elements of oak and wenge (although the wood species is chosen at your discretion). Machining is many times faster and more productive than making the same crafts by hand, and it is on lathes that the main part of decorative wooden goods is made. You can also make candlesticks or a rolling pin on a lathe. It will not be more difficult to make spoons. And where there are spoons, there is also the manufacture of dishes - plates, a festive dish, a glass.

Fans of original decor should try their hand at creating caskets or even chess (the latter version of products is more complicated, requires an accurate eye and a firm hand, fine polishing). Many decorative items cannot be obtained without turning balls. But spherical blanks are also made for other purposes. They become handles in a wide variety of equipment, in furniture. Just for furniture, they can be decorated with decorative carvings; children's toys and beautiful Easter eggs also require special grace.

Separately, it should be said about segment structures, which are cut in parts and then glued together in a special way.

Model overview

Whatever product you are going to create, you need to pay attention to the capabilities of specific devices.

- For example, JET JWL-1443. Its frame is made of cast iron and is quite massive. The headstock is quite flexible. The variator on a V-belt base has 10 typical speeds, the control as a whole is very simple. They note that this machine is made at the level of worthy professional models. You do not need to stop the 750 W induction drive to change the speed. Processing of workpieces and large size is allowed. The device can be connected to a home power supply. The total weight of the machine is 103 kg (packed 121 kg).

- As an alternative it is worth considering Holzstar DB1100... The power of such a machine is also 0.75 kW.It weighs only 92 kg, and the variator allows you to change the spindle speed from 500 to 2000 rpm. It will be possible to process parts up to 110 cm long and up to 35.8 cm cross-section.

- At home, it will work well and Proma DSO-1000. This machine handles both hard and soft wood species. The copier guarantees the production of small series of identical parts. The device is also suitable for construction organizations in need of independent production of certain types of products. Cylindrical, conical and shaped surfaces are successfully developed; current consumption is only 0.4 kW.

Selection rules

It is difficult to choose a lathe clearly, because there are a lot of models in the catalogs. However, some recommendations must be taken into account in any case. Vibration is the main enemy of any turner, regardless of the material being processed and the product being created. The heavier the car, the less it vibrates. This property is especially important in case of insufficient balance of the workpiece.

The distance between work centers is normally 760-915 mm. Longer beds are potentially more efficient, but the risk of vibration is greater. It is better to limit yourself to the length that you really need. The larger the diameter of the workpieces being processed, the more convenient the apparatus.

In professional production, large floor models with powerful motors are used, in ordinary workshops - weaker modifications, which are more compact.

If there is a shortage of space in the room, it is worth choosing machines with shelves for storing accessories. The movement of the attendants should be as smooth as possible. The Morse taper is very useful, increasing the versatility of the equipment. Additionally take into account:

- convenience of speed adjustment;

- ease of startup and shutdown;

- the possibility of reverse (valuable in grinding mode);

- functionality (basic machines are suitable for normal use at home, but no more);

- the minimum size of workpieces;

- automatic or manual feed.

Exploitation

For beginners to work on a lathe, first of all, you should master the simplest techniques, and only then proceed to complex actions. Cutters should be used for soft wood. It is more correct to process hard rocks with chisels. Sometimes sharpening a workpiece correctly means leaving part of it unprocessed; a similar method is needed for round candlesticks and chess pieces. The lower turning style is especially productive, but accuracy is lost with it; the straight European concept is suitable for turning with a particularly low tolerance.

The basics of wood turning involve carefully fitting the workpiece to size. The rounder the disc, the better. The workplace is adapted to the growth of the turner. The detail should be strictly at the elbow level. Not only convenience considerations, but also safety precautions require a stable, comfortable posture, good lighting.

The workpieces themselves are fixed thoroughly. The handlebar is placed just below the torsion axis. The cleaner the job, the slower the spindle turns. Deep penetration of the cutter into the workpiece is life-threatening. It is necessary to work only in overalls, with short-cropped hair or with a headdress.

You can not start work without special glasses and the release of the protective screen... It is necessary to repair and adjust the machine in a disconnected state. The tools are clamped from above with one thumb. Putting other fingers on it is dangerous.

Before checking parts, including measuring them and evaluating the quality of processing, the machine must be turned off; in addition, you will have to take into account the instructions of the instructions and recommendations for specific types of turning work.

The comment was sent successfully.