Features of knurling for lathes

Thread rolling using special rollers is a popular and versatile option used by most craftsmen in production. This solution not only made it possible to achieve high precision threads, but also ensured the compliance of the finished product with the necessary requirements and accelerated the processing of parts.

general description

Knurling, carried out on lathes, is a special technology used to form various surfaces of products. With the help of special tools, craftsmen manage to roll onto parts:

-

mesh;

-

corrugation;

-

risks;

-

notches.

Today, the rolling method of material processing followed by threading is considered a universal option that makes available:

-

improving the working and strength characteristics of products;

-

elimination of defects - cracks, scratches and other deformations;

-

increasing the corrosion resistance of the product;

-

modernization of the element in order to improve operation.

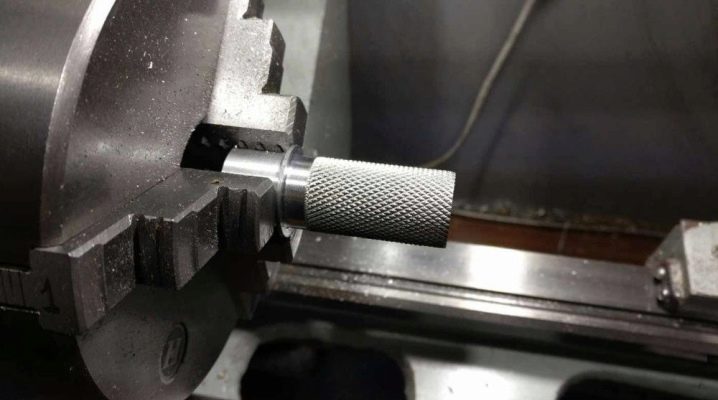

Some details require a rolling procedure so that they can be conveniently used later. For example, special grooves are often made on the heads of screws or handles.

Views

Metalworking involves the use of two types of knurling in lathes.

-

Shaping... They are used when it is required to form teeth and threads. Basically, cylindrical parts are subjected to processing. And also knurling is used to make notches on measuring instruments, which will later become measurement scales. In many industries, knurling is also known as a skewer.

-

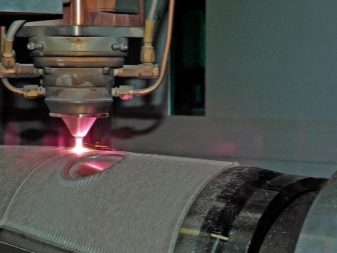

Hardening... Using this technique, it is possible to increase the wear resistance of the product, thus extending the service life. And also knurling increases the strength characteristics of the processed element. In the process of processing, work hardening is applied to the surface of the material, due to which the operational properties are improved. Basically, hardening knurling is used in the manufacture of fasteners, shafts or bushings.

Rolling is carried out using special tools - base and rollers, made of durable stainless steel. The dimensions of the teeth on each of the rollers determine the shape and size of the future thread or other type of processing.

There are the following types of videos.

-

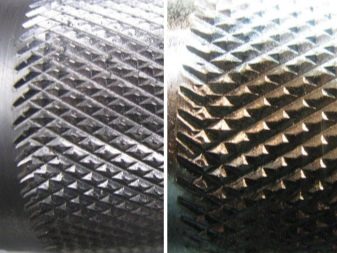

Rolling... Elements are used to form a relief on a surface. To achieve the desired result, it is necessary to install the roller in the holder, which will then be mounted in the tool holder. Knurling rollers are additionally divided into one- and two-sided. The former are in demand when forming a straight pattern, the latter are necessary for mesh corrugation.

- Toothed... Applicable for the formation of teeth, used mainly for machining cylindrical parts. With the help of toothed rollers, the desired parameters can be achieved in one go.

- Universal... They make it possible to form corrugations on various elements: from handles to fasteners. They are also designed to create scratches and notches.

- Standard... These rollers are ordinary balls assembled from hard alloy steel or hardened iron. Some of the elements are equipped with a spring for uniform pressure on the part. The advantage of these rollers is the ability to adjust the pressure force. More often, using standard models, parts of minimum rigidity are processed.

To carry out the work, it is worthwhile to carefully approach the choice of the roller, since the result will depend on the size, shape and performance of the element.

Nuances of use

To complete the procedure, turning equipment is required - a machine. Before starting work, it is necessary to set the revolutions on the equipment - no more than 100 per minute. Powerful models and professional machines are capable of handling the task at once. At home, you will need to roll the product several times.

There are four types of rolling:

-

direct;

-

angular;

-

cross;

-

semicircular.

The first two options involve using a single knurled roller. Cross rolling requires two parts.

The peculiarity of rollers performing semicircular rolling is a special semicircular groove with a radius where cutting takes place. To prevent the part from going beyond the edges during the procedure, the radius of the groove should exceed the radius of the rounding of the part by about half the knurling step.

Other features of using knurls.

-

For straight and cross knurling, the dimensions of the chamfers must be taken into account.otherwise, burrs will form on the surface.

-

When rolling, the diameter of the product increases by an average of 0.5 knurling steps. This must be taken into account when choosing rollers.

-

The knurling step is calculated based on several parameters: the diameter and characteristics of the material, as well as the length of the surface to be processed... For example, for hard materials, choose a coarse step. The same goes for parts with large holes.

-

The thread rolling procedure should be started before finishing the surface of the part.... This is explained by the occurrence of large stresses caused by the rollers, due to which the dimensions of the elements can change.

-

Almost any machine is suitable for the task, equipped with a high power tool post.

-

Before the procedure, the rollers should be thoroughly cleaned with a brush, so as not to harm the surface of the processed material.

Rolling is a complex process, before carrying out which it is necessary to take care of the preparation of tools, materials and assembly of the structure. To begin the procedure, you will need to install the roller in the holder. There are the following types:

-

floating head holder;

-

one- or two-sided;

-

U-shaped;

-

V-shaped.

Universal models of machines make it possible to work with a pair of rollers at once, due to which it is possible to achieve a cross pattern. Other devices allow you to change the depth of the grooves, expanding the capabilities of the equipment.

The comment was sent successfully.