Features of DRO for lathes

The features of the DRO for lathes need to be known in order to use this technique correctly. We'll have to learn the general rules for choosing this type of installation. You should also familiarize yourself with an overview of popular DRO models.

Description and purpose

The machines are now mostly standard equipment. However, foremen and even at professional large enterprises often have a need to improve control of work, to perform it better and more accurately. For this purpose, they produce just the DRO for a lathe. Together with them, raster-type optical rulers are also used. Installation of such devices allows:

- display the most accurate indicators;

- check the position of the tool relative to the axes;

- move the tool during work in accordance with the set values, preventing the effects of wear and backlash inherent in various gears.

The DRO on the lathe allows operators to make fewer mistakes. All devices are equipped with a screen. It displays clear and unambiguous information collected by the sensors. Elementary calculations help to analyze this information. The system will show the real placement of the machine axes with full and incomplete selection of backlashes.

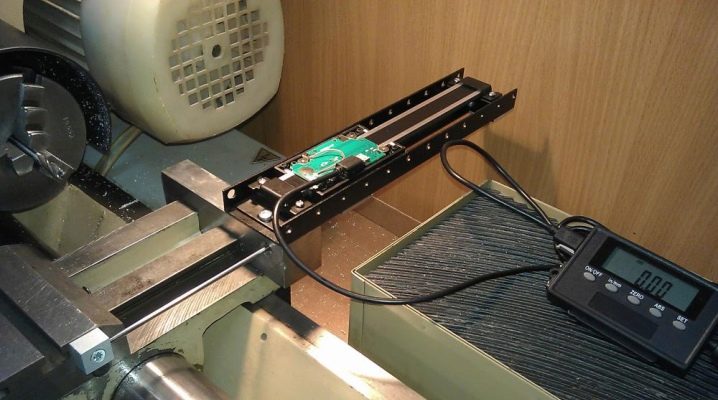

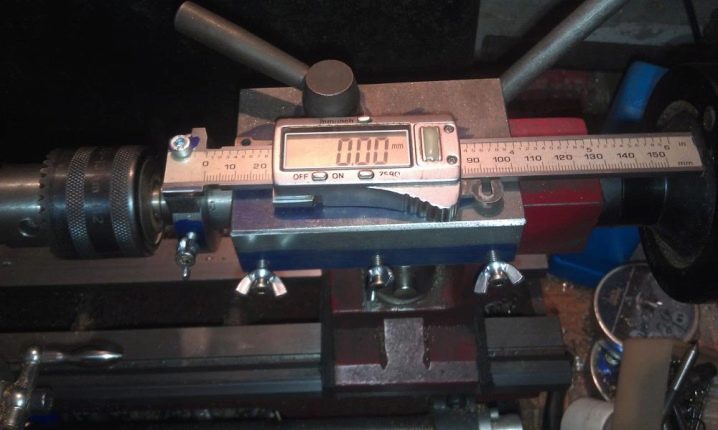

Optical rulers provide accurate measurement of the placement of working parts in relation to the selected axis. A blank is preferably used as such an axis. Optical rulers can also measure angular positions.

The study heads send a special optical signal. The required graduation scale is formed on a glass rail, and they are set there with very high accuracy.

Optoelectronic converters are invariably included in the DRO. They superbly track linear movement. With proper use of this technique, the number of defective parts is reduced. Modern models are distinguished by the presence of auxiliary options:

- calculate the radius of the circular arc;

- allow you to drill openings along inclined lines;

- make it possible to process corner surfaces;

- output to zero;

- replace the calculator;

- help to work out the internal grooves of a rectangular shape;

- serve as a digital filter;

- adjust the indicators for the section of the tool, if necessary;

- can memorize a large number of instruments (up to 100 or even up to 200 sometimes);

- convert angular indicators to linear, and metric to non-metric units.

Popular models

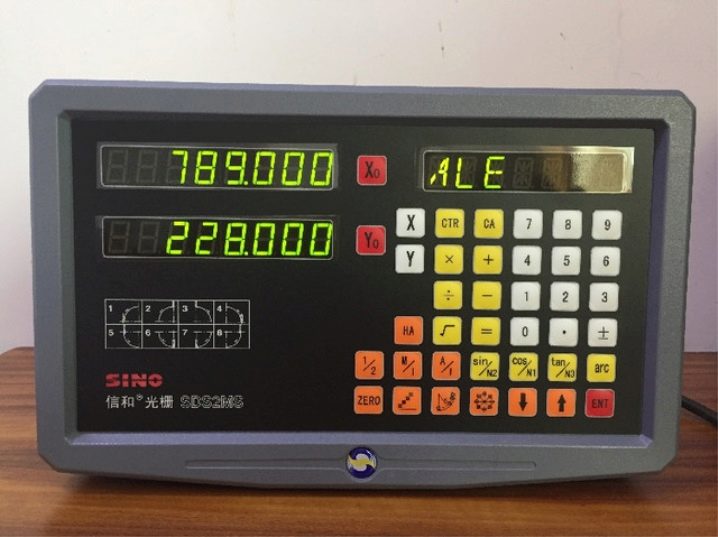

The DRO Lokshun SINO deserves attention. This is a budget series that has proven itself excellently not only on lathes, but also on other machines. The system is designed to use 1, 2 or even 3 function axes. Other parameters:

- range of measured length - up to 9999 mm;

- discreteness of the connected lines - 0.5, 1, 5, 10 microns;

- emitted signal in TTL format.

It is worth taking a closer look at Innova products. For single-axis measurements, the 10i is a good choice. It is also useful as adding an additional axis to the previously had a single-axis DRO machine. Main features:

- interaction with encoders of the TTL standard (both linear and circular);

- measurement accuracy is approximately 1 micron;

- power supply from a 220 V network;

- security of the steel body;

- admissibility of mounting with a bracket or in a machine board.

The 20i system works on 2 axes. It has the same level of accuracy as the previous model. Similar requirements apply to encoders. The steel body is also protected. The power supply from the household power supply is again provided.The indication of the number of the used instrument is supported.

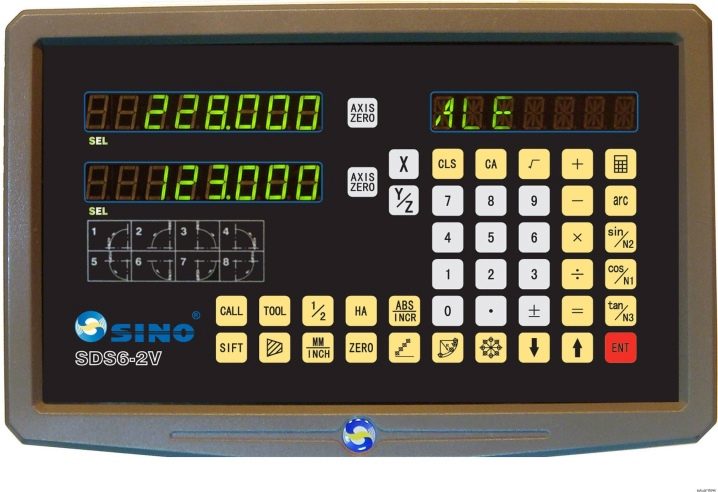

SDS6-2V can also be considered as an alternative. Such a DRO works on 2 axes. Potentially also compatible with milling and grinding machines. The screen is lit quite brightly. Other technical parameters:

- length measurement up to 9999 mm;

- generating a TTL signal;

- network cable 1 m long;

- power supply with voltage from 100 to 220 V;

- dimensions - 29.8x18.4x5 cm;

- dust cover;

- 2 neodymium magnets and 2 fixing brackets included in the delivery set.

Selection Tips

Opportunities should be preferred to digital readouts with liquid crystal displays. They are more convenient to use than old screens. However, there are also opposite opinions. Some experts point out that LED or fluorescent indication is visible at much larger viewing angles.

You must understand that The DRO cannot be cheap anyway. If there is no extreme need, it is easier to buy optical or magnetic rulers instead. It is important to understand the number of axes that will be used. Another nuance is the accuracy of determining specific values and the level of error.

Feedback on specific models may also be helpful. Otherwise, all the required information is contained in the technical data sheets.

The comment was sent successfully.