All about vertical drilling machines

After reading this article, you can learn everything about vertical drilling machines with and without CNC, tabletop and column-mounted products. Their general purpose and structure, the scheme of the machine tool for metal and the main units are characterized. Models and key nuances of choosing such a technique are described.

Peculiarities

The main purpose of vertical drilling machines is the production of blind and through holes. But they can be used not only for drilling in the narrow sense; auxiliary processing of holes obtained by other means is also allowed. It is possible with the help of such a device to drill out passages that require the highest possible accuracy. These systems are especially effective for internal threading and metalworking to create discs. Therefore, we can conclude that this technique is almost universal in its application.

On the listed operations, the possibilities of using vertical drilling devices are not exhausted. Often such devices are bought for organizing small-scale production and for domestic purposes. But many other useful components can be added to the main nodes according to the scheme.

The basic principle of operation is to move the workpiece in relation to the tool. The active part of the device is fixed with special cartridges and adapter sleeves.

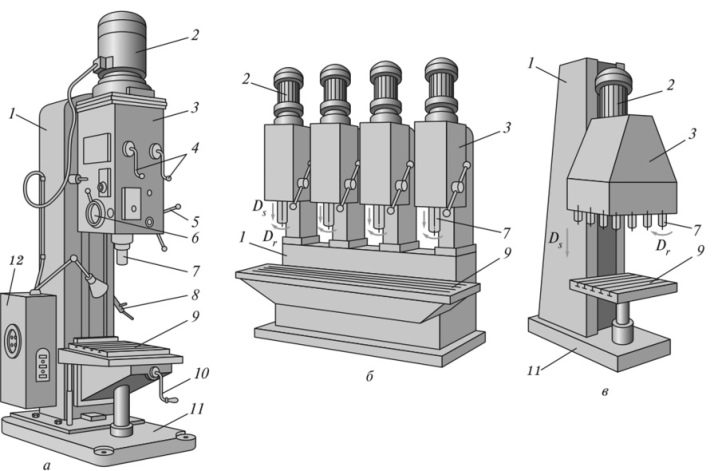

The structure is formed in such a way that it is most convenient to operate with large workpieces. The productivity of vertical drilling equipment is quite high. The descriptions usually also emphasize the simplicity of service work. The most typical scheme is based on the use of a base plate, on top of which a column is placed. But there are other options, each of which has strengths and weaknesses.

Drilling machines will be your faithful helpers in:

-

mechanical production;

-

assembly shop;

-

repair and tool production;

-

the work of repair shops at transport and construction, at agricultural enterprises.

Specifications

The key parameters of any vertical drilling machines, regardless of their brand, are:

-

the composition of the processed materials;

-

the ability to drill holes of a certain depth;

-

spindle overhang and lifting above the working surface (these parameters determine how large workpieces can be processed);

-

distances between the top points of the spindles and work tables (base plates);

-

a variety of the number of revolutions at the spindle;

-

the distance the spindle moves in 1 full revolution;

-

number of spindle speeds;

-

weight of the device and its dimensions;

-

electricity consumption;

-

three-phase or single-phase power supply;

-

cooling characteristics.

What are they?

Tabletop

This version of the machine usually has a single-spindle type of execution. In this case, it is impossible to count on special performance. However, the compactness of the device is quite a convincing advantage. If you need to carry out several treatments at once, you will have to use multi-spindle heads. But this is nothing more than a half measure, compensation for weakness.

Fixed on a column

In such models, the support column serves as a support for power units, gearboxes and spindle heads. In many cases, an option is provided to shift the work table or set of spindles in the desired direction. The column itself is usually not installed on the floor, but is mounted on a machine bed. Along with highly specialized units, universal units can also be used, which allow performing various technological operations.

However, even the most advanced manual or semi-automatic equipment does not allow large holes to be produced in large workpieces efficiently enough.

It is necessary for such manipulations to use large gear units. Most of them have long been supplied with CNC, which further expands the functionality. In this case, it will be possible to prepare almost any hole with particularly high precision. Operators can be guided by the indications of the display unit. Some versions are supplied with an XY table and / or a vise to further improve handling efficiency.

The best manufacturers and models

The products of the Sterlitamak Machine-Tool Plant are valued for their high quality. For example, gear model CH16... It can drill holes with a nominal diameter of 16 mm in a steel surface. Other technical points:

-

weight of workpieces to be processed up to 30 kg;

-

height of workpieces up to 25 cm;

-

the distance between the spindle axis and the column is 25.5 cm;

-

net weight 265 kg;

-

the spindle taper is made according to the Morse 3 system;

-

working surface 45x45 cm.

You can also pay attention to the products of the Astrakhan machine-tool enterprise. First of all - АС 2116М. This system drills, reams and countersinks equally well. It can also come in handy when reaming and threading. The spindle stroke reaches 10 cm, the spindle taper is made in Morse 2 format, and the working surface is 25x27 cm.

An alternative can be considered Zitrek DP-116 - a device with a power of 0.63 kW, powered by an ordinary household power supply. Its practical features:

-

spindle overhang up to 6 cm;

-

cartridge 1.6 cm;

-

distance between spindle and table 41 cm;

-

device height 84 cm;

-

net weight 34 kg;

-

the table rotates 45 degrees in both directions;

-

the diameter of the functional column is 6 cm;

-

12 speeds are provided.

The ranking of the best includes PBD-40 machine from Bosch... This model is relatively inexpensive. She will be able, using special drills, to prepare holes with a cross section of up to 1.3 cm in metal. If you drill wood, the size of the holes can be increased up to 4 cm. Reliability is also beyond doubt.

A good choice is also worth considering Triod DMIF-25/400... Such a device is capable of operating at a voltage of 380 V. Other technical features:

-

power 1.1 kW;

-

spindle stroke up to 10 cm;

-

table size 27x28 cm;

-

the size of the holes drilled up to 2.5 cm;

-

racks 8.5 cm;

-

it is possible to switch between 4 high-speed modes at feed and 6 spindle speeds;

-

variable speed by means of a V-belt;

-

machine weight 108 kg;

-

deviation to the side up to 45 degrees.

Stalex HDP-16 cannot produce such holes, its working diameter is 1.6 cm. The column section is 5.95 cm. The height of the machine reaches 85 cm. 12 different speeds are provided, and the operating voltage is 230 V. The spindle cone is made according to the MT-2 system, and the quill is 7.2 cm in diameter.

It is appropriate to end the review at JET JDP-17FT... This belt-driven device operates at a voltage of 400 V. The table is 36.5 x 36.5 cm in size and can be tilted 45 degrees to the right and left. The total power of the electric drive is 550 W. The net weight is 89 kg and the spindle can move at 12 different speeds.

Selection Tips

The power level is one of the key indicators. Machines for 0.5-0.6 kW are well suited for home or garage use. When planning to create a workshop, you need to choose models for 1-1.5 kW. The most powerful samples are already connected to networks not 220, but 380 V. The drilling diameter is selected individually.

It is important to pay attention to how accurately the holes are made; in household models, the accuracy is lower than in professional equipment.

In addition to these points, you need to pay attention to:

-

security;

-

quality of management;

-

automatic feed option;

-

possibility of supplying lubricating and cooling liquid;

-

consumer reviews;

-

the frequency of use of the equipment, and the activity of its loading.

For home use, it is advisable to choose light, small-sized equipment. The easier it is to move it to the right place, the better. Minimum noise is also important. For the most part, the low-noise, compact vertical drilling machines have a bench-top format. Such models prepare holes with a cross section of 1.2-1.6 cm, in addition, they help to save very expensive electricity.

In garages, workshops, or even more so in workshops, there is no longer a special limitation on volume. Much more important is the level of performance and functionality. In such conditions, floor machines with stable footrests are the most attractive.

If you need to form the largest holes, you will have to give preference to gear machines. Taking the cheapest models will hardly be justified, except for those who work occasionally.

The comment was sent successfully.