What are mini drilling machines and how to choose them?

For a number of craftsmen and just amateurs, it is important to know what mini-drilling machines are and what they are. Models for drilling printed circuit boards deserve attention. However, there are other types of small machines, and the specifics of their equipment, which makes the choice of miniature models not as easy as it seems.

general description

Large drilling equipment does not cover all the needs for this kind of equipment. Often, small mini drilling machines are much more practical for punching holes in parts made of different materials. They can hardly make large cross-section passes. However, in their segment of tasks they cope well and even demonstrate high accuracy. The capabilities of such equipment allow you to create threads and perform other technological manipulations.

The small dimensions of the machines allow them to be installed in any convenient place, even in small workshops. Current consumption will be limited, almost always you can get by with a connection to a regular 220 V network. Mini drilling machines can be used for drilling on glass or for processing printed circuit boards. In both cases, they work very subtly and successfully perform precise manipulations.

Such devices are valuable for radio amateurs and modelers alike.

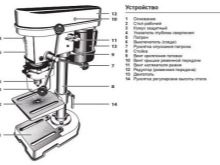

The mini drilling machine accomplishes the task with 2 movements. The main one is the twist of the drill, which is fixed in the spindle head. But the vertical movement of the drill, or, as they say, the feed movement, is also important. The key structural element is always the support base. The vertical stand is based on it. The stand has guiding elements on the outside. The head moves along them vertically. The drive is installed from the inside of this head. The inner segment is sometimes provided with a box to adjust the spindle speed.

Advanced bench-top machines provide automatic oil flow to the working mechanisms and cool down the processing area. The rotating force is transmitted using gear and belt drives. The drill is held in the spindles by a cam or collet chuck. Fastening is done with a special key. The vertical movement of the spindle unit together with the drill is provided by a special handle located on the right of the working head.

Some devices allow you to automatically adjust the depth of the drilled holes.

Specifications

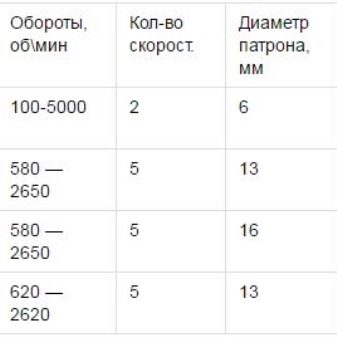

The characteristics are roughly the same as those of the larger equipment. The only difference is limited capabilities. The key parameter is power, which determines both the practical ability of the machine and the current consumption.... The rate of rotation of the spindle unit is also important; it can be from 200 to 3000 turns in 60 seconds. In advanced models, there are gearboxes that allow you to set up to 12 speeds of rotation.

It is worth paying attention to the gap from the end of the spindle to the plane of the working table. This moment will determine the highest height of the workpiece. It is also impossible to ignore the smallest and largest cross-sections of the drilled channels: this is one of the key parameters by which one can generally evaluate the machine.The mass and size of the bed must also be evaluated - both the ease of movement of the machine and whether it turns out to be stable depend on them. Finally, the last technical characteristic on the list (but not by value!) Is the variety of drills that can be used in working with a particular model.

Views

By construction type

The most common type is vertical drilling. It is capable of performing the widest range of technological operations. This technique is often chosen just for equipping workshops in the house. Radial drilling machines cannot be ignored either. They help to develop passages with predetermined steps.

Additionally, there are:

- jig boring;

- single-spindle;

- multi-spindle;

- boring;

- diamond boring;

- horizontal drilling machines extremely rarely used in the home segment.

By versatility

The most common miniature universal machines... They are suitable for a wide variety of operations. You can use them to cut threads, make holes, and countersink metal - and this list is far from complete. Special models are designed with the expectation of performing a small number of operations of more or less homogeneous content. Such operations can be done either one after the other or simultaneously.

For workshops, it is also sometimes relevant to drill deep holes in the same type of products. This makes it possible to carry out relatively large orders. A specific group of mini-drilling machines is intended for this purpose. They, like the previous version, can usually perform several operations. However, some of them are designed for only one job.

Rigging

Basically, drilling mini-machines are designed to work with fiberglass printed circuit boards. Simple drills do poorly with this material and quickly lose their sharpness. Carbide drills are preferred. They work much better on fiberglass. But such a working part can easily break from lateral loads, so you should be more careful with it.

However, it does not work out to restrict oneself to drills alone. In addition to them, for work you will need at least another rotary vise, which makes it easier to clamp the parts. A rotary coordinate table is also useful. They use it for any complex manipulations. Chucks, bushings, spindle adapters are used in the same way as on large machine tools.

A boring head can also be considered a device for a mini-drilling machine. Additionally, parts are used that simplify work and guarantee greater safety. Measuring devices are distinguished into a separate category. Along with rotary tables, inclined coordinate tables are also used. You can hold the workpieces to be processed using not only a vice, but also clamping bars.

The types of planks are very diverse. They are made in the form of a bracket, a T-shaped retainer and other products. Vices differ from planks in a more serious mode of operation. In addition to the actual bar element, they also contain a base and a screw device.

Bushings and adapters fit directly into the spindle head. They have only one task - to adjust the diameter and performance of the spindle itself. The chucks are much more perfect, they allow you to fix the drills much easier. The drill chuck also makes it possible to adjust the inner diameter. In addition, nozzles and many other devices are also used - but almost all of this will have to be bought on your own, since such accessories are not added to the basic delivery sets.

Auxiliaries are primarily lighting and lubrication devices. It is not necessary to illuminate the work area with ordinary bulbs.... In some cases, advanced diode devices are used, which provide parameter adjustment.

A high-quality product makes it possible to quickly change the position of the light source and the intensity of the glow, sometimes even the color - which is very important for precise work.

What to consider when choosing?

First of all, you need to focus on the range of tasks to be performed. Or rather, on the cross-section of the drills that can be used. If you have to work with large parts, it makes no sense to choose mini-machines with drives less than 1000 W. You should also pay attention to:

- operating mode;

- reviews about a specific model;

- the depth of the passable holes;

- the ability to perform auxiliary operations (countersinking, threading, and so on);

- the ability to work with a specific material;

- equipping with cartridges of a certain type;

- overheating protection;

- power reserve;

- number of speeds;

- organization of management.

The comment was sent successfully.