Choosing a coordinate table for a drilling machine

Drilling machine is a special equipment for processing various materials. An additional device in the form of a coordinate table will help to improve and speed up the operation of the installation. It is worth considering in more detail the features of the product, the possibilities and nuances of choice.

general description

The XY table is a movable platform made of high strength alloy steel. The surface of the device is treated with anti-corrosion compounds. The main purpose is to fix the workpiece being processed on the machine. There are several ways of attaching a part, among the common ones:

-

the use of mechanical fasteners;

-

the use of vacuum devices;

-

the use of its own weight of overall structures.

Coordinate tables have a different number of degrees of freedom: from 2 to 3. Some of the models produced are capable of moving exclusively in the horizontal plane, the rest can change their position vertically.

Tables with two degrees of freedom are used mainly for processing flat workpieces. The latter are suitable for working with parts with a complex configuration.

Such tables are installed on machines that are in large industrial enterprises where large amounts of material are processed.

The table is attached to the machine so that it can be moved later. The following types of drives are responsible for changing the position of the device:

-

mechanical;

-

electric;

-

with a CNC system.

Each table also has a base, which ensures a long product life and increases its strength. Usually the base is made from:

-

become;

-

cast iron;

-

light alloys.

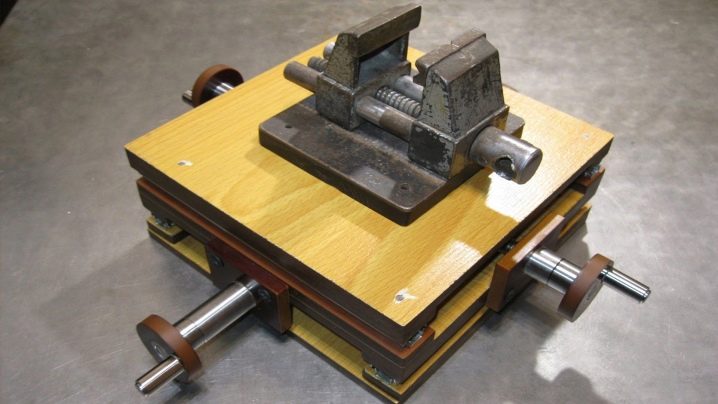

The latter are based on aluminum. It should be noted that such structures are suitable for processing light parts, since they are not able to withstand heavy loads. More often, wood and plastic materials are processed on tables with an aluminum base. Steel and cast iron tables are installed mainly on industrial machines, where we are talking about weighty loads.

Additional table elements.

-

Guides. One of the important components that ensure the movement of the table in planes. The product moves with the help of carriages mounted on rail guides. Elements can be of different lengths. If necessary, docking with other guides is possible, if this does not impair the movement of the overall structure.

-

Mechanical transmission. They are responsible for converting the rotational movement of the shafts into the translational movement of the carriages, ensuring the timely movement of the structure. Manufacturers use three types of gears: rack and pinion or belt, as well as ball screw.

The coordinate table is an indispensable element of any machine where workpiece fixation is required.

Varieties

Manufacturers produce different models of XY tables. Classification according to the design scheme provides for the division of products into:

-

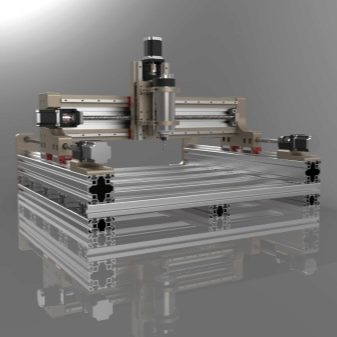

cross;

-

portal.

Tables assembled according to the first scheme are installed on universal drilling machines. Such devices are suitable for processing complex parts, since they provide reliable fixation of the workpieces and open access to the part from three sides. The latter is achieved due to the design features of the table.

Gantry products are mounted on machines that require the formation of holes in the workpieces.It is worth highlighting the long tables made of aluminum, which are mounted on professional machines used in large enterprises. The use of such a device increases the functionality of the installation, allowing you to fix:

-

tool connectors;

-

cooling and lubrication drives;

-

neutralizers of harmful substances;

-

devices for removing dust and shavings.

Fixation of additional equipment takes place on a workbench provided by the table design.

Popular brands and models

Pivot tables are updated every year. In addition, manufacturers regularly release new models, and it is not surprising that the user is lost in such a wide range. To speed up and simplify the search for a suitable device, a rating was formed from the top 3 coordinate tables.

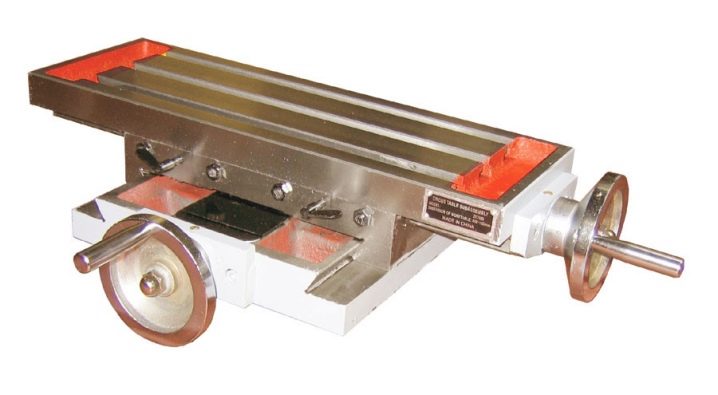

KRS-185 Visprom, Proma

Standard model with no pivot capability. It is used for installation on machines where milling, drilling or grinding of workpieces is planned. The table provides secure fixation of the workpiece using the provided T-slots and fasteners. Pros:

-

compact size;

-

long service life;

-

high-quality performance.

The product is capable of longitudinal and transverse feeds.

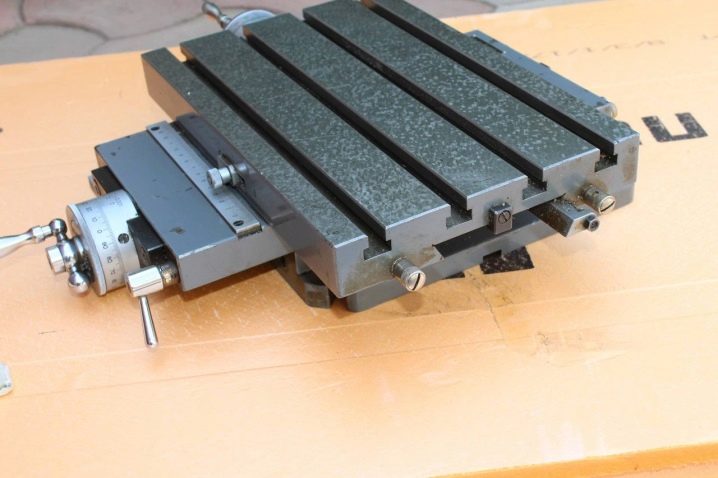

AKR-1-303, CNIC

Coordinate type with two degrees of freedom, capable of turning. It is used as additional equipment on various machines. The length of the working surface of the product is 330 mm, which makes the model compact. Pros:

-

expanding the capabilities of the drilling unit;

-

long service life;

-

high performance characteristics.

The only drawback is the lack of a coolant chute.

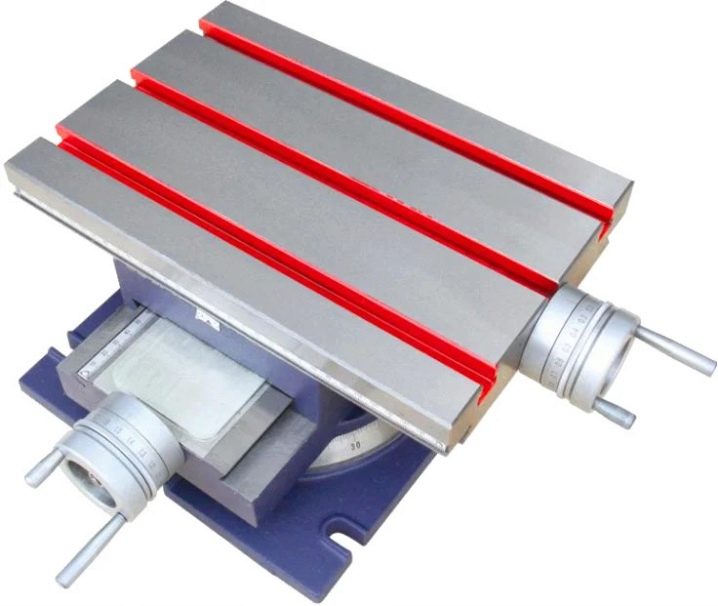

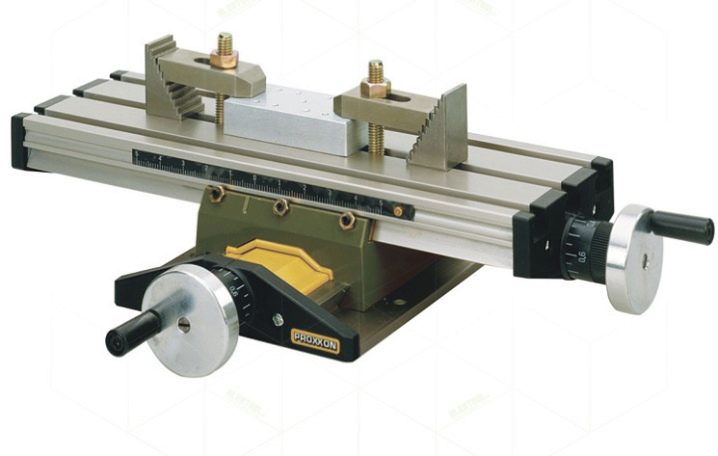

CT 70, Proxxon

A table for milling workpieces, which is installed on drilling machines with a bed. The device is compact in size and can be moved in both longitudinal and transverse directions. Features of the model:

-

the perfect combination of lightness and strength;

-

Smooth surface;

-

movable ruler;

-

adjustable handwheels.

The connection of the elements is manually adjusted. If necessary, the user can remove the backlashes.

Nuances of choice

Buying an XY table requires a responsible approach, as the market has a wide variety of models. When choosing a device, it is worth considering:

-

number of axes of movement;

-

dimensions of the coordinate pad;

-

type of drive;

-

way of control.

Additionally, it is worth paying attention to the capabilities of the product and the compliance of the product parameters with the requirements of regulatory documents. And also the masters advise to take into account the distance between the holes for fasteners, on which the reliability of fastening the table to the equipment depends.

Other factors are equally important when choosing an XY table.

-

Material. When working with large and heavy parts, preference should be given to steel or cast iron models. If you plan to process wood or other lightweight products, you can buy an aluminum model.

-

The quality of the grinding of the working surface. The drilling accuracy directly depends on it. And also it is worth clarifying the presence of a protective layer, which affects the service life of the product.

-

Guide type. The cheaper the model, the less fluid the movements will be. When considering this parameter, it is also worth paying attention to the type of drive.

-

Control method. It is advised to give preference to tables, the movement of which can be adjusted using the CNC. However, when using simple equipment, you can opt for standard manual fixtures.

The XY table is an important part of the design of any machine, which ensures reliable fixation of the workpiece and stable operation of the equipment.

The comment was sent successfully.