All about radial drilling machines

Knowing everything about radial drilling machines is necessary to equip home workshops and small industries. In this case, it is absolutely necessary to take into account what the purpose and structure of CNC machines is, what models exist. It is also worth understanding what it means if the machine has the largest drilling diameter, what are the general scheme and characteristics.

Peculiarities

The main purpose of the radial drilling machine is to process large, heavy workpieces. This technique is readily used both in one-off production and in the production of small series. It is often purchased by repair enterprises, machine-building (including transport) plants. Such a device can work with workpieces at any point without reinstallation. Therefore, less time is wasted and the overall drilling accuracy is increased, since misalignment is eliminated.

Instead of the part itself, the spindle moves. What attracts attention in the description of the radial drilling machine is that it works very quickly. Drilling takes place in a short time, even when handling hard metals. Simplicity of technical service is also an important advantage. As a result, production manipulations are performed not only quickly, but also very efficiently.

Radial drilling equipment allows you to get both through and blind holes. The main nodes that make up such a technique:

- taps for cutting;

- drill;

- countersink mechanisms;

- sweep.

Additionally, other equipment is installed. If you have a CNC, you will also need an electronic unit. All parameters of the planned production operation are entered into such a computer device. The drilling pattern may differ because the angle to the surface of the part varies widely. The holes can be in the form of a cylinder or a cone.

All details are thoroughly fixed before starting work. The size of the machine itself can vary significantly. Work with parts made of various materials is allowed.

Radial drilling equipment is capable of performing both roughing and semi-finishing and main (finishing) machining. It is also possible to work inside the end holes.

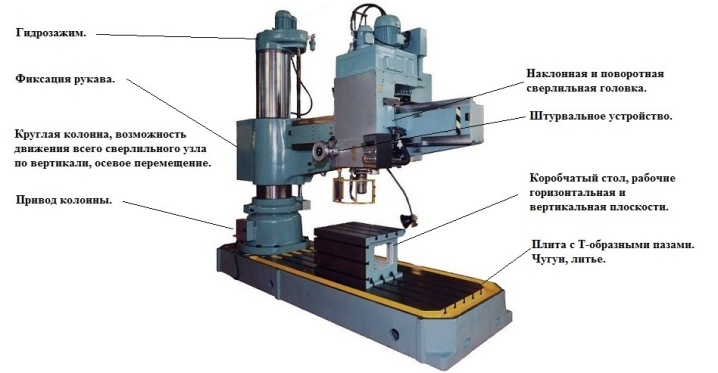

In addition to the bases characterized by high rigidity, the following are also envisaged:

- columns in the form of a cylinder;

- traverse;

- drilling head;

- electrical and hydraulic systems (including gearbox).

The twisting and movement of the spindle quill play a key role. The basic principle of operation involves the alignment of the midpoint of the channel and the axis along the coordinates. In this case, the workpiece remains stationary. Corner processing is carried out exclusively when mounting at a certain angle using special equipment. The beds are predominantly cast from gray cast iron.

Small parts can be installed either on side tables, or on a specially processed area of the desktop. Taking workpieces out of the working field is rarely practiced. Each such action significantly reduces the accuracy of manipulations and can only be justified by unique requirements. An important role is played by the pivot column, which is placed vertically on the bed. Its rotation along its axis is on roller bearings.

From above, the column is complemented by a mechanism that raises or lowers the traverse. The movement of this mechanism is due to the connection of the electric motor.The console, aka arm or trunk, is mounted on a column. Such a part is equipped with a separate electric drive. For comfortable work, all control of the system is carried out on the drilling spindle head.

Species overview

Many industrial radial drilling machines are very large and heavy. They belong to the category of stationary equipment. This technique allows for general-purpose technological manipulations. In some models, a column is added that can move along the guides along the workpiece. Some large machines can themselves move along the workpiece along the rails.

Almost all modern models are supplied initially with CNC.

There is no particular sense in abandoning the use of such a technique. The elimination of electronic control components creates so many inconveniences and limitations that it outweighs any savings. The tabletop device is usually portable, which is extremely convenient for working in small workshops and private houses. Such models are widely represented on the market. Separately, it is worth mentioning the versions with a rotary table, which are produced by leading manufacturers.

These machines are usually suitable for countersinking and reaming holes. They can often be used for end trimming with cutters. Sometimes other operations with body parts are possible in a mechanical workshop. Some models can be equipped with a variety of additional devices. Thanks to them, high-performance work in high-volume continuous production becomes possible.

Marking

The symbol always begins with the number 2, which indicates that this is a drilling device. The second number (5) indicates the radial type of drilling. The next two digits are the largest bore section that can be obtained. The letter at the end can denote a major upgrade (A) or increased accuracy (P).

The best manufacturers and models

Attention should be paid to the enterprise "DMTG RUS"... Large-scale assembly of equipment has been deployed there in accordance with the latest innovations in mechanical engineering. A good example of the products of this enterprise is considered Z30100x31... The spindle stroke reaches 50 cm, and the size of the working table is 80x125 cm. The spindle cone is made according to the MK6 system, the weight of the product is 20 tons.

An alternative is the model Z3050x16 from the same manufacturer. Its main characteristics:

- work table measuring 50x63 cm;

- spindle stroke - 31.5 cm;

- engine power - 4000 W;

- weight - 3500 kg.

You can also buy equipment "StankoMashStroy"... The production in this company is certified for compliance with ISO 9001. Machine Z3040x10 drills holes up to 4 cm in diameter. Its motor power is 2200 watts. The mass of the device is 1400 kg, and the section of the column is 24 cm.

The Gomel Plant of Machine Tool Units also has a decent reputation. Among its products are radial drilling machines, including 2K550V... They have been certified to meet the new EU requirements. The guide arms and columns in this model are made of heat-treated metal. Clamping of the sleeve in the column and clamping of the column in the plinth occurs automatically, and the machine weighing 3500 kg is able to drill holes in steel with a diameter of up to 55 mm.

From far abroad products it is worth paying attention to WEIDA Z3040... The sleeve unfolds at an angle of 180 degrees in relation to the inner column. 16 spindle speeds are provided. Any unit is made of especially durable metals and alloys. The main motor power reaches 4000 W.

What to look for when choosing?

Do not think that if the machine has the largest drilling diameter exactly what you need, then you can stop at this point. There are other characteristics that are definitely worth exploring.

Attention should be paid to the performance of the system (both the main engine and individual units).For private work, a power of 600 W is enough, but for some kind of serious workshop, at least 3000 W is needed.

It must be understood that the more powerful the machine, the greater the current consumption. Advanced devices have many different functions. But it's worth considering carefully whether you really need a laser pointer, illumination, and so on. You also need to consider:

- spindle speed (very good if there is a multi-speed reducer);

- the height (calculated from base to spindle);

- spindle overhang (an increase in this indicator allows you to make holes further from the edge of the part);

- power supply (for home - 220 V, for industries - 380 V).

An important point is how often and how intensively you plan to use the equipment. Continuous use means daily use of at least 2 hours. If the documentation stipulates "intermittent periodicity", then the machine can be started sporadically for several minutes. For home use, choose lightweight, inexpensive and mobile devices. It is also necessary to study the reviews.

Nuances of operation

Correct use of a radial drilling machine requires careful measurement of dimensions. They should be monitored repeatedly during work.... Before starting, you need to check whether everything is connected correctly, whether the fasteners are secure. Wear personal protective equipment when using the machine. The drill must hit exactly the right place; small parts are held with pliers or fixed with a vice.

Deep drilling is carried out in several stages. The drills are removed from time to time and clean the channel from the shavings. When preparing a through hole, it is necessary to slow down its movement just before the drill exit.

Before starting work, you need to check the condition of the floor. If it is bad, you cannot talk about the safety of the device.

Dust and shavings should be removed regularly. All working parts are checked for serviceability and quality of sharpening in advance. In the event of extraneous noise or unjustified heating of individual parts, you must immediately turn off the machine and eliminate the cause of the problem. Contact with cutting and other moving parts must be avoided when using the machine. In the event of a sudden shutdown of the machine or a power outage, the equipment is supposed to be de-energized, and work can be resumed only with a thorough full check.

The comment was sent successfully.