Features of channels 18

A channel of 18 denomination is a building unit, which, for example, is larger than channel 12 and channel 14. The denomination number (item code) 18 means the height of the main bar in centimeters (not in millimeters). The greater the height and thickness of the walls of the unit, the greater the load it will withstand.

general description

Channel number 18, like all of its brothers, means that the product is produced in the form of a hot-rolled beam. Cross section - shortened U-shaped element. The production of channel elements is carried out in accordance with GOST standards, corresponding to a certain list of assortment samples. On the basis of these Gosstandards, the channel 18 is marked according to the final subspecies, allowing variations in values without a significant loss of strength characteristics. State Standard No. 8240-1997 allows the production of channel structures for general and special applications.

According to GOST 52671-1990, carriage-building units are produced, and according to Gosstandart 19425-1974 - for the automotive industry. The general standards are GOSTs for TU.

All channels (except bent ones) are hot-rolled units. First, blanks-strips of liquid, white-hot steel are poured, then the slightly solidified alloy passes through the hot rolling stage. Here, special shafts are used, which, until the unit has frozen and has not completely hardened, carry out the formation of the main element with the main and side walls. What has frozen and formed the channel elements is fed into the conveyor furnace, where heating and cooling are carried out according to a special algorithm, which includes quenching and, if necessary, dropping and normalizing. The products that have passed the stage of thermal annealing after cooling are stored and sent for sale.

Thanks to the use of low- and medium-carbon steels, this building material is easy to weld, drill, fasten with bolts and nuts, sharpen, cut. The processing of the channel of the 18th denomination is carried out by practically any methods - and without special restrictions, including manual inverter-arc welding. It is easy to saw, which allows you to quickly convert a batch of 12 meters to a batch of 6 meters and so on. According to GOST, a slight deviation in the direction of increasing (but not decreasing) the length is allowed: for example, a batch of 11.75 m can be sold as 12-meter segments. This small margin is made in order to prevent the collapse of the structure, for which the length is a little short.

Bent channel elements are made on a special bending mill. The throughput of this machine can reach hundreds of running meters of finished products per minute. Elements with equal flanges (bent) are made from coiled steel strip of a standard quality level. Steel has a high quality - it belongs to the highest quality structural materials. But elements with unequal shelves are made of steel of normal quality. According to GOST 8281-1980, steel may be low-alloyed.

Length variations correspond to the length of equal products. And the compliance of products with GOST standards guarantees a level of quality acceptable for all customers and contractors.

Assortment

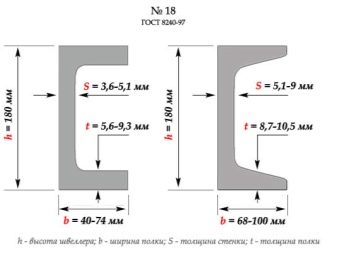

Channels 18P - parallel shelf elements. Channel 18U has a slope of the side walls, which lost their mutual parallelism during production. The slope of each of the shelves can reach several degrees - relative to the initial perpendicular state.18E products are an economical option, the walls and shelves may turn out to be somewhat thinner than in the case of units of the 18P / U type. 18L is about twice as light as 18P and 18U - this is indicated by the noticeably smaller width of the shelves and the main wall, and their somewhat smaller thickness. Theoretically, 18E and 18L can be obtained using thermal deformation (thermal stretching) of the channel components 18U and 18P with their direct "rolling" to the desired condition, but in practice, rolling is made according to the dimensional proportions already characteristic of the units of the "E" and "P" subspecies. The purpose of the rental is to provide acceptable values for width, thickness, length and weight.

In addition to 18-P / U / L / E, specialized 18C units are also produced. They also have non-parallel sidewalls. The 18th denomination is also represented by additional subspecies - 18aU, 18aP, 18Ca, 18Sb. These four modifications represent the accuracy class. The suffix "A" denotes a high class of accuracy, "B" - increased, "C" - normal. But "B" in some cases also means "carriage" products, therefore, in order to avoid unnecessary misunderstandings, sometimes this letter marker is put down twice. The tenth, last type - 18B - is oriented exclusively as a "carriage" product: on its basis, the carcasses of the rolling stock (motor) are built.

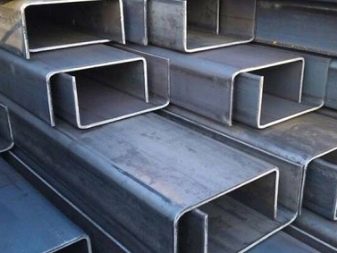

However, products of the 18th denomination are also produced as a bent channel. This means that the product is obtained by the method of cold "sheet-bending" rolling - finished sheets, cut into strips, are passed through a bending machine. The advantage of the cold-rolled channel 18 is the more respectable appearance of its edges, namely a particularly smooth surface. This is important when the structure is not supposed to be hidden from prying eyes in a closed plastering or under a wooden (or plasterboard, panel) flooring. The bent channel 18 is produced as units with equal and unequal shelves in width.

Dimensions and weight

In order to determine the total mass of the channel-bar lot and choose which truck is used for delivery in each specific case, an important characteristic comes to the fore - the weight of 1 m of product. Since the channel beams are cut - at the request of the customer - into segments of 2, 3, 4, 6 and 12 m, they take into account how these segments will be lifted up during the construction of the object (for example, when it is planned to build a full-fledged interfloor ceiling even during the construction of a country house). The thickness of the sidewall for 18U, 18aU, 18P, 18aP, 18E, 18L, 18C, 18Ca, 18Sb is 8.7, 9.3, 8.7, 9.3, 8.7, 5.6, 10.5, respectively, 10.5 and again - 10.5 mm. For the first four (in the list) samples, the thickness of the main face is 5.1 mm, then the values are in the following order: 4.8, 3.6, 7, 9 and 8 mm.

The width of the shelf here is, respectively, 70, 74, again 70 and 74, then 70, 40, 68, 70 and 100 mm. The inner radius of smoothing between the main wall and the sidewalls will be, respectively, 4 times 9 mm, then 11.5 and 8, then 3 times 10.5 mm. The weight of one meter of samples represents the following values:

- 18U and 18P - 16.3 kg;

- 18aU and 18aP - 17.4 kg;

- 18E - 16.01 kg;

- 18L - 8.49 kg;

- 18C - 20.02 kg;

- 18Са - 23 kg;

- 18Sat and 18V - 26.72 kg.

The density of steel is taken as an average - about 7.85 t / m3, this is the value for steel alloy St3 and its modifications. A significant difference with the above values could appear, for example, when replacing St3 with stainless steel, however, stainless steel channels are a huge rarity: it is irrational to produce them as such, since steel is easily galvanized and primed (painting elements with primer-enamel for rust).

Applications

The height and thickness of the walls are not the last characteristics. When calculating the beam weight (load) characteristics, both its own weight and the pressure in kilograms exerted on each square centimeter (or meter) of the channel base are taken into account. When calculating the load from the supporting channel structure on the downstream walls, it is important to optimally position the channel elements so that they do not sag under the weight of other building materials, as well as, possibly, people, furniture and equipment in the building or structure. Due to its ability to be installed both “lying” (on the channel wall) and “standing” (on the shelf edge), the channel bars work effectively against bending effects. However, under a load that exceeds the allowable safety margin, the channel units will begin to bend downward.Excessive bending will lead to the failure of individual sections or to the complete collapse of the entire floor.

The main area of application for channel 18 is construction. The construction of horizontal ceilings (between floors), as well as sheds and purely vertical structures - frame-monolithic components - fell under this category. Channel 18 can even be poured into the foundation - from those sides where it is planned to create additional stiffening ribs. Small bridge crossings are also built from channel 18. For the construction of full-fledged road-rail bridges, however, much larger elements are used - “forty” channel, and not relatively small ones, like the 12th ... 18th denominations. Channel metal products are also used in mechanical engineering. The "carriage" element 18B is proof of that.

Channel 18C is used in special conditions - for example, when the foremen were faced with the task of changing or retrofitting a tractor or bulldozer, as well as making a separate trailer for a passenger car. These products are tolerant to both linear and axial loads of increased values.

The comment was sent successfully.