All about channels 40

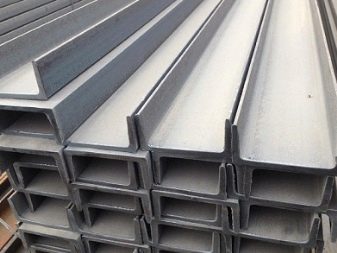

Channel products are the most common building material. Along with round, square (reinforcement), corner, tee, rail and sheet varieties, this type of profile has taken one of the leading positions in the construction and mechanical engineering sectors.

Description

Channel-40, like its other sizes (for example, 36M), is made mainly of steel grades "St3", "St4", "St5", 09G2S, as well as a number of aluminum alloys. Naturally, aluminum is several times inferior in strength and elasticity to steel structures of similar transverse dimensions and length. In exceptional cases - on an individual order - one of several stainless alloys with Russian marking such as 12X18H9T (L), etc., is used, but such products are more expensive than their other counterparts, made from less "exclusive" alloys. This product is manufactured by the hot rolling method - unlike a rounded, bent channel element, conventional production in conveyor furnaces is used here, and not bending of already finished sheet products (strips) on a profile bending machine

In fact, these elements are a slightly different type of profile, but they are similar to the U-part, in which the so-called. shelves, or side panels (side strips): they are much narrower than the main strip, which sets the rigidity of the entire part. GOST 8240-1997 serves as the standard for the release of the "40th" product denomination.

Compliance with uniform rules significantly reduces the cost of producing such parts and components, allows you to speed up and simplify the development of steel structures: from construction to machine, in which this channel is used. The values of the parameters of the channel 40 are known in advance.

Dimensions and weight

The dimensions of the channel 40 are equal to the following values:

- side edge - 15 cm;

- main - 40 cm;

- sidewall thickness - 13.5 mm.

Weight 1 m - 48 kg. Manually lifting such a weight is beyond the power of one person. The real mass is slightly different - due to small differences allowed by GOST - from the reference one. With a small mass of this product, the price per ton is not too high. The main qualities - resistance to bending and twisting under load - remain at a fairly high level. The height of the product does not fully depend on the series and standard size of the products. For the “40th” profile, it is fixed at 40 cm. The radius of the inner smoothing of the corner is 8 mm from the outside and 15 mm from the inside. The width, height and thickness of the shelves are indicated in the drawings, respectively, by markers B, H and T, the rounding radii (outer and inner) - R1 and R2, the thickness of the main wall - S (and not the area, as indicated in mathematical formulas).

For products of the 1st type, whose side plates are inclined inward, the average value of the thickness is indicated. This parameter is measured at the midpoint between the edge of the side strip of the channel element and its main edge. The accuracy is determined by the half-difference between the values of the width of the side wall and the thickness of the main one.

For channels 40U and 40P, for example, the cross-sectional area is 61.5 cm2, for the economical (less metal-intensive) version 40E - 61.11 cm2. The exact weight (without averaging and approximation) of elements 40U and 40P is 48.3 kg, for 40E - 47.97 kg, which fits into the GOST 8240 standards. The density of technical steel is 7.85 t / m3. According to GOST and TU, the real length and dimensions (in cross section) are indicated taking into account the following values:

- measured length - the value indicated by the customer;

- a multiple value "tied" to a measured value, for example: 12 m is doubled;

- non-dimensional - GOST sets a tolerance that the manufacturer and distributor will not exceed;

- some averaged or deviated - within the tolerance according to GOST - value - this value is permissible;

- measured and unmeasured values, due to which the batch weight differs by a maximum of 5%.

The channel is not produced in the form of huge coils, it is impossible to reel it into a bay - otherwise its radius would significantly exceed a kilometer. You can be convinced of this by comparing the channel with rail rental - and looking at the map of the once laid tracks. Channels are produced only in sections that can be longer or shorter, but no company can make, for example, a 40-kilometer channel 40 solid.

The slope of the 40U channel does not exceed 10% of the perpendicular location of the walls, which characterizes its counterpart - 40P. The distance between the side walls does not exceed 40 cm.

Products are produced by cold or hot rolling, the quality is average or above average.

Weldability of 40P and 40U channel elements is very satisfactory. Before welding, the products are cleaned from rust and scale, degreased with solvents. Welding seams are applied based on the thickness of the product: it is desirable to use the thickest (about 4 ... 5 mm) electrodes for electric arc welding. If this is not possible - a too responsible structure due to an excessively high load - then in order to avoid a rapid collapse and subsidence of the structure being built, gas welding of a semi-automatic or automatic type is used. However, multi-storey buildings, bridges and other structures are made using welded and bolted joints: here one complements the other.

Products are easily turned, drilled, cut by both a mechanical (using saw blades and saws) cutter and a laser-plasma cutter (accuracy is the highest, there are almost no errors). Available in 2, 4, 6, 8, 10 or 12 m sections. The cost of long-term rental - per meter - may be lower; the largest possible amount of waste (scraps), from which it is unlikely that it will be possible to make something useful. Basically, equal-shelf products are produced: varieties 40U and 40P do not imply the manufacture of products with different shelves.

Application

The construction of metal-frame monolithic buildings and structures is unthinkable without the use of corners, fittings and channel bars. After laying the foundation - as a rule, a buried-strip foundation with a monolithic structure - a structure is installed, thanks to which the structure takes on its basic outlines. The channel also allows you to reconstruct an already built building or structure. Modern technologies involve the gradual abandonment of the brick base, which has a significant impact on the foundation. This means that the cost of equipping the latter can also be reduced. Thanks to the appearance of the equal channel channel, professional shipbuilding became possible, for example, the construction of icebreakers. Another area of use is the construction of offshore drilling platforms, the task of which is to pump oil.

The mechanical engineering industry also involves the use of channel units in the form of a basic structure, which is subjected to the load from the axles of the wheels (running) of a moving machine.

The use of the same channel 40 reduces the metal consumption and material consumption of the facility being built or equipment under construction. And these factors, in turn, provide a reduction in investments, the most advantageous competitive position in the market.

The comment was sent successfully.