Features of stainless steel channels

Features of stainless steel channels are just the information that many consumers of metallurgical products need. These channels can be bent and other types of steel AISI 304 and 12X18H10T. Welded channels 120x50x3 and other sizes deserve attention.

Description and production features

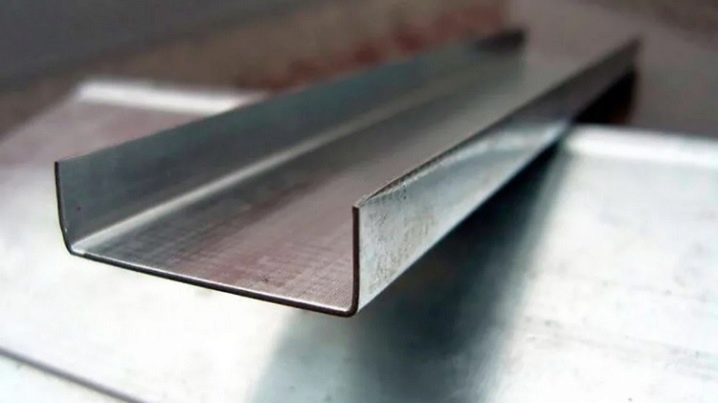

The modern stainless steel channel is shaped like the letter P. The use of such structures is very wide. They are made from a wide variety of metal combinations. Channel bars, including bent ones, are usually made of AISI 304 steel. But AISI 316 alloy can also be used. Such metals are strong and resistant to the effects of various substances of natural and natural origin. The combination of strength and reliability is largely due to the specific section of the product. It is precisely its shape that guarantees excellent resistance to mechanical overload.

Channels can be produced by hot rolling or by laser welding. In the first case, the metal is heated to high temperatures and driven through specially designed machines. This technique is very time-consuming. However, its disadvantage is its high cost. Changes in the composition of steel during hot rolling often lead to unacceptable consequences.

Laser processing is energy-intensive, but it is carried out only locally, directly in the areas where structures are connected. The laser makes it much easier to make a stainless steel channel than a rolling machine.

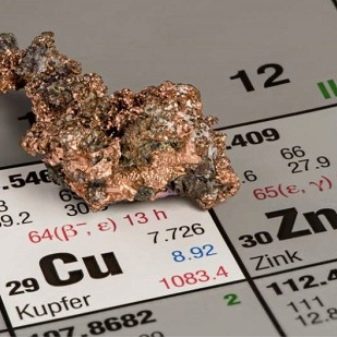

AISI 304 is a good all-round grade. It perfectly tolerates acids and other corrosive substances. The cost of such a substance meets the needs of consumers. For alloying use:

- nickel;

- chromium;

- copper;

- manganese.

Steel 12X18H10T contains 0.12% carbon... This austenitic alloy is produced in electric arc furnaces. Corrosion resistance is ensured with a large amount of chromium. The combination of titanium with silicon helps to suppress the corrosion between crystals. The growth rate of the grains when heated will be less.

Views

Stainless steel channel 120x50x3 mm is very popular. And also there are dimensional positions:

- 50x30x2;

- 80x40x3;

- 100x50x4;

- 60x30x3;

- 160x64x5 mm.

Laser welding, despite its disadvantages, has an important advantage - it allows you to get products of different sizes. The cold-formed profile can also be used in practice.

However, it will invariably have rounded corners. Because of them, the scope will be limited. The service life, regardless of the manufacturing method, will be very long.

Application

Corrosion-proof channels are actively used to strengthen load-bearing metal structures. They are used to strengthen columns and frames. Such products are in demand not only in construction, but also in the food industry. It is very important that the parts being produced are not mechanically stressed. By using AISI 316 steel, a higher resistance to caustic and corrosive substances can be guaranteed.

And also channels can be designed for use in:

- automotive industry;

- arrangement of shafts of coal mines;

- production of wagons;

- construction of bridges;

- equipment of overhead lines.

The comment was sent successfully.