Features of channel 20 and their application

Channel products are like two corners located parallel to each other and welded together with a longitudinal seam along the line of contact. Such a channel can be made, but in practice, ready-made products are produced - from a solid strip, bending it from the edges at a softening temperature.

general description

Marking a channel, for example, number 20, does not mean that this is the size of its central or side walls in millimeters. For such purposes, there is a simple P-profile, the walls (central, as well as side shelves) of which are approximately equal in thickness, and not twice (or more than twice) narrower than the main, central one. Channel 20 has side flanges of equal or different widths. The height (width) of the main wall is 20 centimeters (and not millimeters, as a beginner would think when he first encountered workpieces of this type).

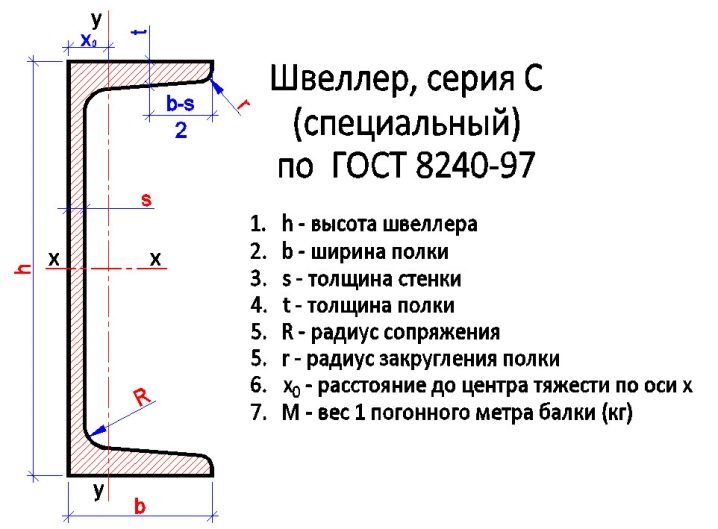

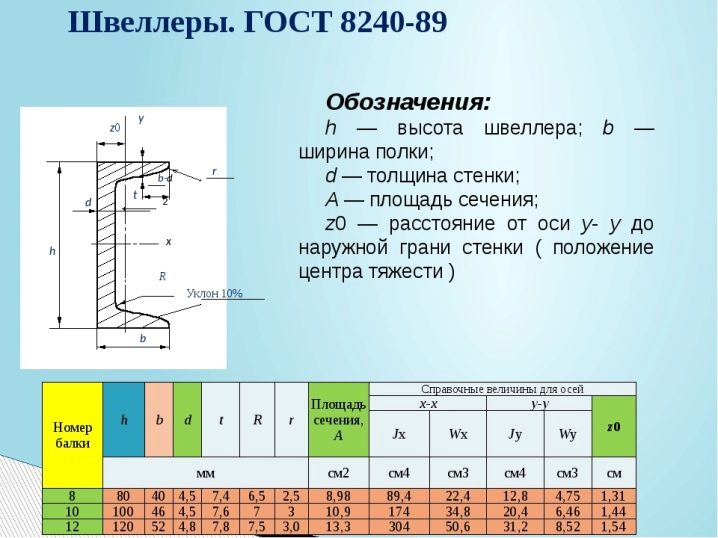

A channel with side walls equal to each other is a hot-rolled product, in some cases it is indeed bending... Bending of the steel strip is carried out lengthwise on a profile bending machine. Rental is made in accordance with with the standards GOST 8240-1997, bending - in accordance with GOST 8278-1983. If the channel has side walls of different widths, then bending of the sheet sources is carried out, followed by cutting them after the bending procedure. The same channel 20 is made from low-alloy steel like 09G2S.

The channel is mainly produced from black and similar modifications of steel, less often - it is made from stainless steel (in a very limited quantity). The usual execution of shaped channel profiled steel, used as component parts, passes, depending on the type of use, through the stages of one of the technologies.

- The steel billet is converted into a channel element after a hot rolling procedure - on a machine with a huge throughput.

- Thin-shelf elements, made mainly of non-ferrous metal, are formed on a profile bending machine. In this case, cold pressing is used.

As a result, the manufacturer and his customers receive a flat channel element that is smooth on all sides, immediately suitable for construction and some other sectors of the national economy.

Technical requirements

In most cases, ordinary steel St3 or alloy C245, C255 is used for making channel 20. The main requirements for safety and labor protection (construction of buildings, structures where such a channel is used) in terms of technical indicators are as follows.

- The safety factor should be threefold. For example, the weight of brick (foam block) masonry above the lintel of a window or door opening, for example, 1 ton, must correspond to a three-ton load on the channel element. The use of 20 or another value of the channel depends on the design recalculation of the structure or building. Between floors, although the main load from the overlying floors is taken by the slabs of reinforced concrete floors, part of the load still falls on the channel lintels of window and door openings. This means that at first the most reinforced channels should be installed on the floor. If all these requirements are violated, then in this case the 20 channel will not withstand the entire load. As a result, the element can bend and fall out, which, as a result, is fraught with the destruction of the house.

- The steel should not be too brittle. The fact is that, often dismantling (breaking) old buildings, dismantlers are faced with the fact that from a blow with a sledgehammer or ingot on special equipment, channels that have not even been subjected to strong rusting break. But the channel is capable of breaking under a significant load. Brittleness is promoted by the composition of the steel from which it is made: phosphorus and sulfur in the steel alloy, exceeding the content of 0.04%, lead to the formation of red brittleness - structural fracture of the steel product with instant or long-term overload.

As a result, it is impossible to use any, the cheapest steel for channel bars. To prevent the channels from bursting suddenly, the sulfur content according to GOSTs should not exceed 0.02% (by weight of the composition), and the phosphorus content should remain in an amount no more than the same 0.02%. It is extremely difficult (and expensive) to completely remove all sulfur and phosphorus from steel, but it is quite possible to reduce their content to trace amounts.

- The steel must be sufficiently heat-resistant and heat-resistant... If suddenly a massive fire breaks out in the building, it will heat up. The channel, having heated up to a temperature of more than 1100 degrees, will begin to bend under the load of the wall built over it. For this purpose, even if not hardened, but sufficiently heat and heat-resistant steel is used, which does not lose its bearing properties even when heated to a bright red glow.

- Steel should not rust quickly. Although the channels are painted after the construction of the walls and floors of the building (before finishing work), it is desirable to use steel with a high chromium content. It is clear that channels are not produced from stainless steel (it is chrome-containing by 13 ... 19%), but steel with a mass fraction of chromium up to several percent is considered a standard solution.

Finally, so that the opening does not collapse, the tab of the indent from the window or door should be of the order of 100-400 mm.

If you save on the length of the channel and lay, for example, 5-7 (and not at least 10) centimeters of indentation (the so-called shoulder), then the masonry under the shoulders will crack from the edges of the opening, and the wall above it will crumble. If you lay too large a shoulder, the total calculated load on the foundation and the underlying floors will exceed the design one (in the project, all load values are clearly calculated). And although it will be within the limits of the maximum permissible standard, the building may still be damaged before its design MTBF passes. Sawing and subsequent welding of the channel with arbitrary pieces is not allowed - select in advance the fragments that provide optimal indents on both sides of the openings.

So, in this example, the 20P channel has a height along the main wall of 20 cm, a height along the side (equal) shelves - 76 mm, bending radii of the corners - 9.5 and 5.5 mm.

Assortment

- Marker "P" means that the side walls are parallel to each other: this sample of the channel is similar to a large-sized U-profile, whose side walls were shortened along the entire workpiece.

- Marker "L" reports that the accuracy of the shape of the channel billet is low (a lightweight sample that is easy to manufacture).

- "NS" means an economical version of the U-channel.

- "WITH" means that a highly specialized channel is made to order.

- Marker "U" - the channel has a certain (not right) angle of inclination inward: the side walls are bent (not outward).

- "V" - carriage channel,

- "T" - tractor. Both of the latter types have a clearly defined, specific field of application.

The standards for the manufacture of channel structures, including 20, have changed several times. The last Russian (non-Soviet) GOST determined the best values for the parameters of channel products, at which these blanks withstand an extremely high load, previously unattainable.

Dimensions, weight and other differences

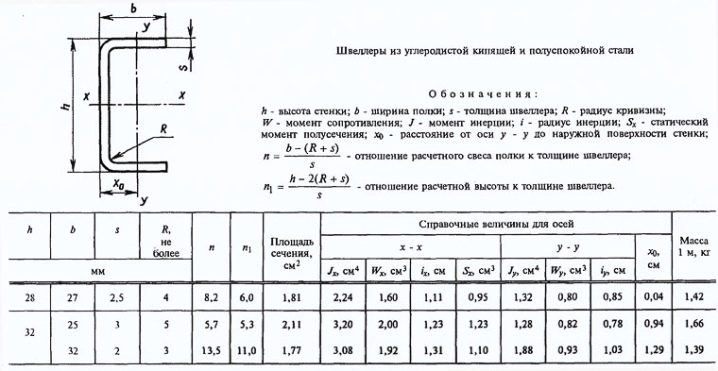

The range of the channel is represented by the following varieties. The steel used for the production of these blanks has a density (specific gravity) of 7.85 g / cm3. The cross-section of the elements is such that the optimal thickness corresponds to the declared one. The total surface area of the channel is equal to the sum of the external and internal components, summed up with the areas of both edges and cross-sections.

|

GOST channel 20 |

Name |

Main partition height, cm |

Main partition thickness, mm |

Side wall width, mm |

Side wall thickness, mm |

Running meter weight, kg |

|

Gosstandart 8240-1997 |

20U |

20 |

5,2 |

76 |

9 |

18,4 |

|

20P |

18,4 |

|||||

|

20L |

3,8 |

45 |

6 |

10,12 |

||

|

20E |

4,9 |

76 |

9 |

18,07 |

||

|

20C |

7 |

73 |

11 |

22,63 |

||

|

20Ca |

9 |

75 |

25,77 |

|||

|

20Sat |

8 |

100 |

28,71 |

|||

|

Gosstandart 8278-1983 |

the same brands |

3 |

50 |

3 |

6,792 |

|

|

4 |

4 |

8,953 |

||||

|

80 |

10,84 |

|||||

|

5 |

5 |

13,42 |

||||

|

6 |

6 |

15,91 |

||||

|

3 |

100 |

3 |

9,147 |

|||

|

6 |

6 |

17,79 |

||||

|

180 |

25,33 |

|||||

|

Gosstandart 8281-1980 |

also |

4 |

50 |

4 |

there are no strict standards for the weight of the workpiece |

Letter markers allow you to immediately clarify how specific samples were produced and what parameters they should have. Channel billets are available hot-rolled or cold-formed.

Reference parameters of a separate type and name of channel products are recalculated per one running meter in accordance with the tabular values... Having received information about a batch of blanks, the total length of which was a certain number of meters, the deliveryman will calculate the total weight (tonnage) of the order, not taking into account the increments (or disadvantages) in terms of permissible errors. The weight of channel products that does not correspond to the declared one by more than 6% is not allowed - on the basis of the requirements of the relevant GOSTs.

For example, according to the standards GOST 8240-1997, hot-rolled channel products are produced as follows. Channel 20 hot-rolled (GOST 8240-1989) varieties "P" and "C" - weighted. Signed with marker "A". The length of the workpiece is from 3 to 12 m. The discrepancy in length takes into account its increase by a maximum of 10 cm, but it is prohibited to sell the length of the workpiece less than the declared length. Craftsmen who cut to order, for example, 12-meter into 3-meter workpieces, know about this.

The preparation period for a heavy, lightweight and "economical" channel is determined by the workload of suppliers, but cannot be more than a month from the date of order. These standards are also spelled out in GOST, TU and other relevant regulations. The billets of structural shapes by the hot-rolling method are mainly produced from the composition of St5, St3 of the "calm" or "semi-calm" (not "boiling") version. This requirement is noted in Gosstandart 380-2005. Low-alloy steel 09G2S, 17G1S, 10HSND, 15HSND can also be used - this tolerance is regulated by Gosstandart 19281-1989. The last two compounds are corrosion resistant.

The parameters of the source material used in the manufacture of channels can significantly reduce the mass of metal frames on which the main part of the building or structure is supported.... At the same time, the initial parameters of the erected building are retained until the period of its normal operation expires. The small mass of the cold-formed channel section does not significantly affect the deformation resistance, including bending and twisting.

Using the calculated data, in order to reduce the workload of the master, it is determined whether they need an equal-flange channel blank (in a certain number of copies) or whether it is possible to do with its different-flange modification. But lightweight structures and shelters, devoid of massive brick and reinforced concrete superstructures (walls, frame monolith on a significantly recessed foundation), allow replacing the classic steel channel with a cold-formed aluminum channel.

If there was no option on sale that would finally suit you, then the manufacturing company has the right to offer you an original solution - dressing of the products you requested according to individual values of characteristics that do not go beyond the specific requirements of GOST and SNiP.

So, having a running meter weight of 18.4 kg, the channel segment found use in the construction of hinged, pavilion, terminal, rail (used for a crane), overhead (for industrial workshop premises), bridge and overpass structures. Such channels in bulk (to order) are carried out serially in 60 tons, in the form of stacks or even piece by piece. Information on quality certificates, parameters and number of copies is attached.The channels are transported by truck or rail.

Applications

Shaped channel products are used for welding frame structures. Welded channel frames are characterized by increased physical and mechanical values of their key parameters. The channel is well cut, drilled, turned (milled). For cutting thick-walled (from a few millimeters) with approximately equal success, you can use a powerful (up to 3 kilowatts) grinder, and a laser-plasma cutting machine. Due to the use of ordinary medium-carbon steels as a starting material, channel billets are easily welded by any method - from automatic welding with a gas-inert protective medium to a manual method (after cleaning the edges to be welded along them.

Channel fragments do not lose their characteristics under high load - they are very similar to U-shaped professional steel for ordinary use. Channel products are widely used in a significant number of industries. It is found in the form of parts and components for special crane equipment, trucks, sea and river craft, railway tractors and rolling stock.

The channel is also a component of interfloor and attic-roof structures, ramps (they are used for driving bicycles, scooters, cars and wheelchairs), furniture items. In addition to lintels for organizing door and window openings, the channel is used as an important component for railings, fences and barriers, stairs.

For information on how to properly mount the channel, see the next video.

The comment was sent successfully.