Features of hot-rolled channels and their types

Hot-rolled channel refers to one of the types of rolled steel, it is manufactured using the hot rolling technique on a special section rolling mill... Its cross-section is U-shaped, thanks to which the product is widely used in various areas of construction and industry. We will talk about all the operational characteristics of such channels and their differences from bent ones in our article.

general description

Hot rolled channel refers to one of the most demanded categories of steel rolled metal products. It can be called a truly versatile product, since its area of use includes a variety of industries and construction. The production process is strictly regulated, the most widespread is GOST 8240-89. In accordance with this standard, the channel can be made from steel of various grades and is used in the construction of metal structures of various types, including load-bearing ones.

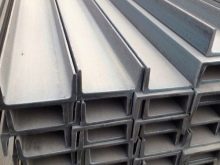

The method of manufacturing such rolled products is suggested by centuries of experience. It is enough just to remember how the blacksmiths used to work: at first they thoroughly heated the metal workpiece, and then intensively processed it with a hammer. In the manufacture of a hot-rolled channel, the same principle is used: a red-hot metal strip is rolled through a section machine, where it is given the required shape in the form of the Russian letter "P".

Channels are made equal flanges, while the shelves can be parallel or with a slope. The unique shape has become the main advantage of the hot-rolled channel and gives the rolled product the properties that are in demand in the carriage, mechanical engineering, and also the construction industry:

- rigidity, thanks to which the product can withstand the most intense forces;

- resistance to any kind of deformation, including tensile and bending loads: this makes it possible to use the hot rolled product for the assembly of weighted metal structures, including load-bearing ones;

- resistance to external mechanical influences: the features of the hot technology for the production of a channel in accordance with GOST completely exclude the slightest risk of weak zones in their structure, in which material destruction can occur in the event of an impact.

Another advantage of any hot rolled steel product is resistance to oxidation and corrosion.... This feature favorably distinguishes rolled products obtained as a result of hot rolling from products made of cast iron. It is no secret that in order to prevent cast iron from losing its high strength due to the appearance of rust during operation, it has to be poured with concrete.

If it is not possible to do this, you have to process cast iron with paint, primer or any other protective compounds. But this will be nothing more than a temporary measure, since after a while such a coating will crack or simply peel off. In this area, oxidation occurs and the channel begins to rust. That is why, when it is planned to erect a steel mill, in which the channel will be operated in aggressive environments (come into contact with humidity or be exposed to temperature extremes), then hot-rolled stainless steel alloy will be the best solution.

However, hot-rolled channels have one feature that somewhat narrows the area of their use. Hot rolled products are not highly weldable. In this regard, in cases where it is required to assemble a welded structure, it is better to give preference to products made by the cold method. Another drawback of a hot-rolled channel is its heavy weight.

However, this is not surprising, given that such a beam is made from a solid steel billet. The steel product has no other disadvantages.

Primary requirements

For the production of hot-rolled products, special alloys St3 and 09G2S are used. Less commonly, 15KhSND steel is used - this is an expensive brand, so rolled products from it are mainly made to order. Manufacturers produce channels as long as possible - 11.5-12 m, this is due to the peculiarities of their operation. However, within each batch, the presence of several metal products of an unmeasured type is allowed.

In addition, GOST accurately establishes the maximum permissible deviation from the established regulations for all indicators:

- the height of the hot-rolled beam flange should not differ from the standard level by more than 3 mm;

- the length should not deviate from the indicators specified in the marking by more than 100 mm;

- the limiting level of curvature does not go beyond 2% of the length of the rolled product;

- the weight of the finished steel channel should not differ from the standard by more than 6%.

Finished metal products are sold in bundles with a total weight of 5-9 tons. Channel with numbers from 22 mm and more, as a rule, is not packed: it is transported and stored in bulk. Beams packed in a bundle are not marked, the marking is contained on a tag attached to each bundle.

Large channel bars contain marking: it is applied with paint to finished products 30-40 cm from the end.

Assortment

Manufacturers offer several different options for the hot-rolled channel. The area of application of the product largely depends on its size and size. Therefore, buyers of rolled steel should know what the alphanumeric symbols on the marking mean. So, all types of channels produced by Russian manufacturers are divided by numbers. Moreover, this parameter corresponds to the height of the shelves indicated in centimeters. The most widespread channels are 10, 12, 14, 16, 20, less often beams with numbers 8 and 80 are used. The number must be accompanied by a letter: it indicates the type of steel product. For example, 30U, 10P, 16P or 12P.

According to this criterion, there are five basic categories of products.

- "NS" means that the shelves of the product are placed parallel to each other.

- "U" The shelves of such rolled products provide for a slight inward slope. In accordance with GOST, it should not exceed 10%. The production of channels with a more significant slope is allowed on an individual order.

- "NS" - economical equal channel channel, its shelves are located in parallel.

- "L" - channel with parallel shelves of lightweight type.

- "WITH" - these models are classified as specialized, the scope of their use is significantly limited.

Dealing with the types of channels is easy. With parallel ones, everything is obvious: the shelves in them are located at an angle of 90 degrees in relation to the base. The first claim for specificity is the models where the side shelves provide for a slight slope. For the products of the "E" and "L" groups, their names are spoken: such models have their own characteristic features in terms of the material of manufacture and the thickness of the profile, which distinguish them from the standard parallel-shelf version. They are made of lightweight alloys, so 1 meter of such a channel weighs less. In addition, such products are slightly thinner, they are used for some specific purpose. The same applies to the C channel bars.

In addition to the listed options, there are also classes of rolled products that are taken into account when creating hot-rolled products: "A" and "B". This designation indicates channels of high and increased accuracy, respectively.

This classification means the method of finishing the product and thereby informs the specialist about the possibility of fitting metal parts in the assembly.

Application

The scope of application of channels obtained in the hot rolling technique is directly related to the product number. For example, a channel with parameters 100x50x5 is widely used as a reinforcing element of metal structures used in the construction of buildings. Channel 14 has a higher density and strength. It is able to withstand significant loads, therefore it has found its application in the assembly of load-bearing structures. As a result of using this type of channel, the structure is as light as possible, while much less metal is required for installation.

Beams made of various types of steel also have their own operating features. Rolled products made from low-alloy alloys are most in demand under conditions when the erected metal structure will be operated at low temperatures. For example, when constructing buildings in the Far North, any other metals become brittle and begin to break. Channel bars are used to strengthen load-bearing structures, carry out engineering communications and erect building frames. The high safety margin of rolled products determines the long service life of the structure: houses with such a "skeleton" will stand for more than a dozen years. The channel is widely used in the construction of bridges. And any columns with monuments in most cases have a base of metal channels with a U-shaped section.

Channel profiles have been used for many years in machine tool building and in the manufacture of road construction equipment. Due to their increased strength, such beams can withstand vibrations and loads of large-sized machines. They are also included in the skeleton of railway cars, where channels are included in the frame elements and bases for fixing the engine.

Without the use of strong beams with a U-shaped section, these machines would hardly have been able to withstand the loads that arise when large trains are moving and during hitching on all kinds of slides.

The comment was sent successfully.