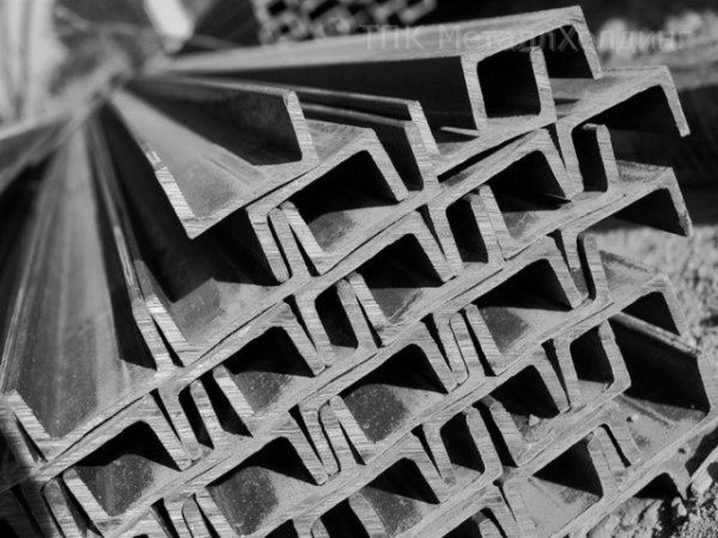

Channel bars 5P and 5U

Channels 5P and 5U are types of steel rolled metal products produced by the hot-rolled process. The cross-section is a U-cut, a feature of which is the mutually parallel arrangement of the sidewalls.

Peculiarities

The channel 5P is produced as follows. The height of the wall is chosen equal to 5 cm. The dimensions of the channel 5P in cross section are the smallest in relation to the range of products, which includes this standard size. Channel bars 5P and 5U are made, as well as their larger counterparts, from medium-carbon steel alloys. The production standards comply with the terms and conditions of GOST 380-2005.

Most often, there are products made from the composition of St3 "calm", "semi-calm" and "boiling" deoxidation. When this sample is supposed to be used in severe frosts - up to tens of degrees below zero Celsius, as well as with increased stationary and dynamic loading, then not St3 or St4 is used, but an alloy of special grade 09G2S, in which the mass percentage of manganese and silicon is increased. Using this combination, it is possible to preserve the characteristics of steel at temperatures of the order of -70 ... 450. Regions located in the zone of earthquakes and modern mountain building will also fall under this category.

Compositions St3 and 09G2S are among the low-carbon ones, due to which workpieces from them, including channel bars, are welded without any particular difficulties. Welding is carried out without heating, which cannot be said about channel elements made of stainless steel and other high-alloy alloys, which, on the contrary, require not only cleaning of the welded edges, but also preheating.

To protect 5P and 5U products from rust, primers are used, as well as waterproof varnishes and paints. A greater level of protection is achieved after preliminary galvanizing: channel billets, cleaned to a shine, are dipped in a bath of molten zinc.

The zinc layer is not afraid of fresh water, including precipitation in ecologically safe areas. However, zinc coating is not able to protect products (the main material from which the workpieces are made) from the effects of salts, alkalis and acids. Zinc, which is not afraid of water, is easily corroded by even the weakest acids.

Dimensions, weight and other characteristics

The parameters of the channel 5P and 5U are tied to GOST 8240-1997. The standards stipulated in these conditions assume the manufacture of channel elements with unbent side strips. The accuracy of the rental is marked with a marker:

- "B" - high;

- "B" is standard.

Typical length of a fragment is 4 ... 12 m, individual customized products are produced in lengths up to several tens of meters.

A channel section of 5P format is produced with a main side height of 50 mm, a sidewall width of 32, a main strip thickness of 4.4, and a sidewall thickness of 7 mm. The mass of 1 running meter is 4.84 kg. One ton of steel makes it possible to produce 206.6 m of channel-type building material.

The weight of 1 m of 5P products is associated with the density of steel - 7.85 g / cm3. However, according to GOST, minor deviations by hundredths of a percent of all the listed values are allowed.

Application

This element, even being massively installed in all kinds of metal structures in compliance with SNiP and GOST, cannot withstand the increased load. It is used in the course of reconstruction measures aimed at redeveloping buildings and structures for various purposes.

As a finishing tool - during a major overhaul - these products have few equal solutions. Reinforced concrete, reinforced with channels 5P and 5U, fully justifies itself in terms of the usual load on the structural elements of a low-rise building or structure. Renovation of the finish is done very often by changing or overlaying the cladding of buildings and structures - here the 5P and 5U elements serve as a frame, for example, to cover the building with soffits.

In some cases, 5P is used for the installation of siding, however, this option is supplanted by the usual thin-walled U-shaped profile, which is not, in fact, channel products. 5U (reinforced element) will withstand finishing of any severity, including steel facing tiles of any configuration.

Elements 5P are used to improve landscape design, the exterior of commercial sites and buildings. A common option is the use of this solution as an improvement of the adjoining area, the creation of architectural compositions.

Channel bars 5P or 5U are able to protect electrical, electronic and hydraulic communications suitable for a building or building, including those lines that are part of the same engineering system and pass inside the object itself.

Channel 5U is used for mechanical engineering. In particular, machine tool construction is a widespread area here: channel elements can be used as composite roller guides, whose surfaces serve as a perfectly flat base for rolling rollers and technological wheels.

The second example is the creation of a production conveyor line, which at certain stages does not experience colossal overload, but directs (almost) finished products to the place of their re-assembly and the final exit from the conveyor.

Channel bars 5P are used for the production of frame vessels, as well as not quite ordinary devices on production lines for all kinds of purposes.

For channels of large dimensions, samples 5P and 5U are intermediate components, but do not bear the main load. Also, these products are used to create the main unloaded metal structure, which nevertheless performs a load-bearing function. To increase the strength of the same structure, frame components for auxiliary purposes (of the second order) are welded or assembled on bolted joints from these channel elements.

The comment was sent successfully.