All about channels 12

Channel-12 is one of the smallest products in this line. The characteristics of the channel in comparison with sheet steel and corners are such that it maintains a significant weight of the structure. Channel-12 is produced in the form of H- and U-shaped elements.

Manufacturing feature

Channel products, like other types of ferrous metallurgy rolled products, are produced by the hot rolling method. Hot-rolled products are cast (baked) in the form of simple blanks, which then undergo a stage of additional processing (cold rolling), or immediately go on sale as roughly processed components. A feature of hot-rolled-channel products is the use of structural elements at those points and along those vectors where the design load is low. It is inexpedient to use the “14th” and larger dimensions instead of the “12th” channel: the steel consumption would come out unjustifiably high.

The production of the 12th nominal channel is subject to the requirements of GOST 8240. Units produced according to this state standard have some differences from other elements of this type. For the production of steel channel products of the 12th rating, steel S345, S245 or ST3, ST4 (or composition of another number), 09G2S are used. The hot-rolled channel is used as load-bearing elements. Internal beams and supports are built from it, which, in turn, are the basis for structures, whose role is to serve as a reliable support for the flooring and all kinds of prefabricated partitions.

The second area of application of channel 12 is secondary structures, which are assigned the role of additional stiffening ribs.

Dimensions, weight and other characteristics

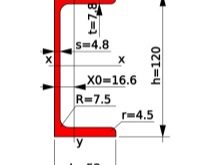

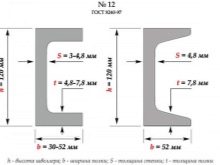

With a height of 12 cm, the channel products have different characteristics. So, for 12U, the side edges extend 52 mm wide, the side wall thickness is 7.8 mm, the main edge thickness is 4.8 mm, the bending radius is 7.5 mm, and the turning radius at the side wall edge is 3 mm. For 12P products, these values are 52, 7.8, 4.8, 7.5 and 4.5, respectively - they almost completely repeat the values of the previous version. For 12E products - 52, 7.8, 4.5, 9.5 and 3 mm. Finally, 12L - 30, 4.8, 3, 7, and turning around the edges of the side edge is not performed. The cross section of different products has the following values: for 12U and 12P these indicators were 13.3 cm2, for 12E - 13.09 cm2, for 12L - 6.39 cm2. From which it follows that 12L channel elements are more than twice lighter than those of their counterparts. This pattern is immediately confirmed in practice: elements 12U and 12P weigh 10.4 kg per 1 running meter, weight 12E - 10.24 kg, 12L - 5.02 kg.

The weight of a product is directly proportional to its cross-sectional area: the volume of steel spent on its production, equal to the product of the base (section) by the height (like a straight prism or rectangular parallelepiped), when multiplied by the density of any steel grade (for example, when elements of all types are made of steel St3Sp) allows you to determine the real weight of the product, confirmed by the values from the reference book. The deviation from the mass according to GOST should not exceed a fraction of one ppm. The density of steel is 7.85 t / m3 - its average value has been chosen. The entire assortment is produced in 12-meter segments, which can be cut into fractional sizes: 2, 3, 4 and 6 m each.A variant is possible when the 12-meter segment is divided into 9- and 3-meter, but such an arrangement of length is made, again , according to the individual order of different customers.

Views

The curved channel of the 12th denomination is not produced, except for the cases when an individual customer order is fulfilled. The fact is that, according to GOST, this is one of the differences in the production of channel 12 from products of other denominations. All characteristics, taking into account possible deviations of channel products, are given in terms of one running meter. Products with a main edge height of 12 cm are subdivided into four product series. This accounting is given according to the geometric dimensions and the outlines of the cross-section of the elements.

- Products 12U - the side shelves are inclined towards each other. They are not perpendicular to the main wall.

- 12П - parallelism of the edges. These samples, on the contrary, have no bias. According to GOST, no deviation resembling a lopsided (like a parallelogram) channel is provided. This arrangement of elements makes no sense either from the point of view of strength and hardness, or from the point of view of elasticity and any geometric reinforcement of the element, which is usually performed in order to achieve higher load values.

- 12E is an economical option for channel products. In this case, the side walls are not bent or beveled.

- 12L - lightweight elements. Their sides are also not bent either outward or inward - neither separately, nor both at once.

Strength category refers to the hot rolling process of standard, high and highest precision.

Marking and stamps

In addition to 12U, 12P, 12E and 12L products, there are other specific brands that determine the specific application of these products:

- 12V - for the carcass;

- 12Т - for the frame of tractors;

- 12C - the decoding of this subtype assumes a special purpose that is not included in any of the above categories.

It is not recommended to use 12E and 12L for construction and heavy machine building, including machine tool building (conveyor building). Both vehicles and large mills, in which lightweight U-sections are used for the manufacture of frames and hulls, are almost guaranteed to collapse when a certain technological process involves a load that comes close to the maximum working load. The use of 12L channels for machines and machine tools is fraught with injuries to workers / drivers and accidents during work / movement. Products 12E have a thinner main strip, 12L - side walls shortened in width and a thinner main edge.

Application

Hot-rolled channel (GKSh) has significant resistance to bending and deflection. Its use is related to both the load-bearing and the auxiliary function in the prefabricated structure. Its scope of use is frame-monolithic or conventional frame construction. Lightweight modifications are used to assemble an additional frame for finishing, for example, for wall panels.

It is used when installing siding, to give the foundation an additional margin of safety. Channel products of the 12th denomination - 12P and 12U - are part of reinforced concrete stairs and fences. On its basis, machine equipment for plants and factories, which is not quite ordinary in its execution, is manufactured.

Bent products of the 12th denomination are most often produced in limited quantities. It has equal and unequal side walls. Equal-sided elements are produced in accordance with GOST 8278-1983, unequal ones - in accordance with GOST 8281-1980. Manufacturing accuracy categories are the same as for hot-rolled elements. Unequal products are limited in areas of use. In an isosceles curved channel, the weight of a running meter ranges from 4.87-10.28 kg, which allows it to be used in structures of thousands of individual types and varieties. In this case, the width of the side edges is 2.5-8 cm.

The specificity of its production is such that a profile machine, bending hot-rolled sheet steel, straightens out unevenness of the surface due to extrusion, which is why ideally smooth and even steel is formed at the output.

Under certain requirements, the bent profile is galvanized - this makes it possible to increase its resistance to rust formation. This means that the appearance of the elements looks much better, which makes it possible to use this product as a decorative, and not just a load-bearing element. In the simplest case, the channel is painted.

The comment was sent successfully.