Range of channels 10 and areas of their application

The range of channels is very diverse. Profile number 10 has its own purpose and use. In the article we will talk about the nuances of its production, varieties, characteristics and areas of application.

Features of production

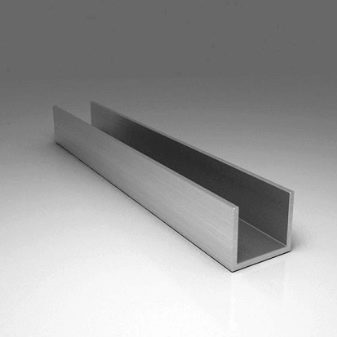

Channel 10 - a metal profile that strengthens metal structures and structures. It belongs to shaped rolled products, in diameter it is similar to the letter "P". "Channel" in translation from German means "skirt". The height of its wall is 10 cm. A profile with a U-shaped section is produced in two ways: hot-rolled and bending metal strips. Hot-rolled steel production method is regulated by GOST 8240-97 and other standards. In the course of creation, a profile is obtained with low weight, small cross-sectional dimensions, and high strength.

Ordinary steel is performed in accordance with the standards of GOST 19425-74. Equal flange profile is produced in accordance with GOST 8278-83. Unequal - in accordance with GOST 8281-80. This channel has a democratic cost and a varied assortment. It is produced from stainless steel or high-strength alloys. Due to this, it has a high resistance to external mechanical stress. It has a high level of resistance not only to axial but also to bending loads. It is characterized by dimensional accuracy, ease of transportation and assembly.

Channel bars are made from alloys with the inclusion of different grades of steel. The compositions differ in technology and raw materials. Most often, constructional carbon and low-alloy steel is used in production. Steels have different chemical compositions. In order not to confuse them, they are given markings St3sp, St3, 09G2S, S245. In addition, aluminum and ferrous metal are used for manufacturing.

The choice of one or another steel depends on the different method of operation. For example, a roll-formed channel weighs less than a hot-rolled channel. It is suitable for the construction of lightweight metal structures.

Heat treatment takes place during the hot-rolled process. Its result is the recrystallization of the steel grid. Due to annealing, the internal stress of the metal decreases, and the indicators of plasticity and toughness increase. Normalization improves the surface quality. Due to the U-shaped section, the resistance to deformation and destruction increases. Due to its shape, the profile is invulnerable. During production, a rectangular metal blank is heated to a specific temperature. Then the soft metal is fed to a rolling mill with rotating shafts.

Due to them, crimping and the acquisition of a U-shape occurs. Initially, the central part is processed. During it, the shape of the channel is M-shaped. Then the alignment and calibration process takes place. The profile is brought to the specified geometry. After cooling, it is sliced, packaged and sent for sale. It is produced with and without hardening. Raw materials are supplied to processing with a small margin, since under heat exposure and shaping, the workpiece slightly decreases in size.

In general, the technique is laborious, but this is justified by the high accuracy of the finished product. However, this rolling is not suitable for a specific alloy profile that changes its physical characteristics when heated. In the manufacture of profiles by cold rolling, specialized roll forming equipment is used.

The principle of operation is based on the use of paired press rolls. They put pressure on the metal sheet from 2 sides.As a result, it takes the desired shape. The process of creating channels is automated, which increases the volume of finished products.

Views

The profile may differ in configuration. In the 10P variety, the edges of the shelves are parallel. The difference between the analogue 10U is a slight slope of the inner edges of both shelves.

The range of channels is great, each letter designation has its own decoding. For example:

- С - special type with customer's parameters;

- L - a profile made of light metal (for example, aluminum);

- E - economical type with less metal volume;

- B - a variety for machine and car building;

- T - channel for tractors.

Steel metal channels are resistant to rusting and allow work at height. The slope of Y-type profiles can vary within 4-10%.

Different types of channels have their own operational tolerances. The marking determines the accuracy of production:

- A - high accuracy;

- B - increased;

- B - standard.

Products differ in the type of strength. Marking "A" indicates a high level, "B" indicates normal values. Channels are stored at specially equipped sites, shipped by weight or meter. The type of material of one kind or another determines its properties and performance. For example, aluminum varieties withstand torsional and bending loads very well. Can withstand vertical impact. They do not come into contact with water. Steel analogs are universal and suitable for use in any spheres of the economy. They can withstand heavy loads with low weight and metal consumption. The geometric characteristics of the section affect the design. Modifications with angled inner edges complicate installation. Analogs with parallel edges are more constructive. Their fastening is universal. It can be a core structure, a column, a tie, a roof girder. By design, the profile assumes a wide range of applications and can be specialized.

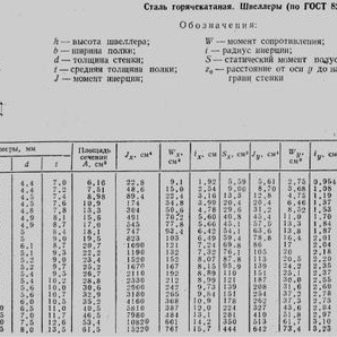

Dimensions and weight

Channel 10 is marked differently. If it is marked in mm, the decoding of size 100 indicates 100 mm of the shelf width. The parameters of a typical profile are 9 m in length. For a profile with a slope of the inner edges, the width of the shelf is 4.6 cm, the wall thickness is 0.45 cm, and the thickness of the shelf is 0.76 cm. The weight of 1 meter of a conventional profile is 8.6 kg. Dimensions of individual products may vary. For example, the length of economical profiles, as agreed with the customer, can vary from 2 to 12 m and more.

The parameters of the counterparts with parallel edges have identical dimensions. For modifications of the economical type with parallel edges, the wall thickness is 0.42 cm. The weight of 1 m is 8.47 kg. The cross-sectional area is 10.90 cm2. The radius of the rounding inside is 0.7 cm, the rounding on the shelves is 0.3 cm. The mass of the channel depends on the length of the perimeter of the cross-section, the thickness of the wall and shelf, and the height of the wall.

The price is indicated per ton and varies from 25,900 to 36,600 rubles. It depends not only on the geometry of the faces, but also on the type of metal.

Application

A profile of this standard size is often used in low- and heavily loaded building structures. He found application in the construction of garages, private houses. It is purchased for the construction of viewing platforms and their supporting elements. It is needed to create longitudinal and transverse stiffeners. It can be a load-bearing and supporting element. It is used as an independent part, or welded into a single structure. With its help, floors and walls are reinforced, communications are laid. It is used in the construction of architectural objects.

In the construction industry, it is also an element for reinforcing concrete structures. In addition, the profile is used in machine tools, shipbuilding, carriage, machine building and heavy industry. Cold-rolled profile type is purchased for repair and reconstruction. It is irreplaceable when assembling greenhouse frames.Channel bars are often used as a budget replacement for I-beams. They are used to reinforce roofs, and are used in multi-storey construction. Their use extends the service life of structures, due to the wear resistance of the material. They do not need straightening and adjustment before starting repair work.

Due to the U-shape, they are universal. Suitable for any construction task. Have an even distribution of the load under static pressure. They have a low price, the number indicates the strength class. Can be used in an aggressive environment, inert to biological effects. They can be used in the construction of structures operated in different climatic conditions, including regions with cold climates, places with high humidity.

Depending on the variety, they are used in landscape design. Suitable for installation in environments with special requirements for hygienic cleanliness.

The comment was sent successfully.