Differences between a channel and an I-beam

I-beam and channel - types of metal profiles that are in demand both in construction and in the industrial sphere... Steel products have high strength characteristics and a long service life, but at the same time they have several differences and are considered absolutely different from each other.

What is the difference visually?

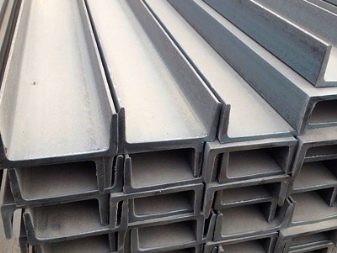

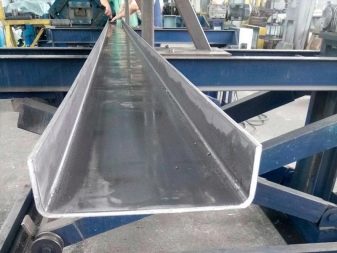

First, you need to figure out what each rental is. Channel - a product with 2 shelves fixed on the wall, has the shape of the letter P. A similar profile is divided into:

- channels U-shaped section hot-rolled;

- channels U-shaped section bent.

Regardless of the type, it regulates the production of channels GOST 8240, which also indicates the regulatory characteristics of existing brands and subspecies of channel blanks.

I-beam - a metal product consisting of two vertical shelves, the centers of which are connected by a wall... It is characterized by increased deflection strength and reliability, is produced in lengths from 4 to 12 meters and has a solid H-shaped section.

The production of such elements is regulated by two regulatory documents: GOST 8239 and GOST 26020.

What is stronger and more durable?

It should be noted right away that I-beam surpasses the channel in any way and is considered the most reliable among rolled metal. Now we need to figure out why. The element is equipped with two shelves, each of which protrudes from the wall by a certain length. The main load falls on the shelves, so the strength of the product increases in comparison with the same channel. The peculiarity of the structure of the I-beam is that the loads act vertically on the profile. The wall, in turn, begins to resist them, not allowing compression forces to destroy the section. Therefore, it is rather difficult to twist the beam.

The forces that the channel takes are much higher, and the reason is the shelves, which act as a one-way lever... In addition, the degree of load is determined based on where the force is applied and how it is subsequently distributed over the shelves. So, the rigidity of the I-beam wall of the shelf is provided from two sides at once, and the channel is provided only from one side, and this is one of the main differences between the strength characteristics of the profiles. You can view the compression resistance indicators and other parameters in GOST for both the channel and the I-beam. As a result of comparing the data, it will be possible to conclude that the indicators of the latter are much higher.

The main criterion for comparison is the moment of inertia, and it is higher for I-beams.

Differences in application

I-beams are rolled products in demand in construction, which are used as load-bearing beams in the construction of large objects:

- bridges;

- high-rise structures;

- industrial buildings.

The channel is best used in low-rise construction. It is also often used in the construction of outbuildings. It is worth noting that, regardless of the purpose, both elements are used both as floors and as roof elements.

Comparison of other characteristics

The difference between the two profiles also lies in the peculiarities of production. I-beams are produced by welding flanges and webs. Production includes several stages, the main ones:

- preparation of blanks;

- assembly of the profile structure;

- welding elements with each other.

Very rarely, I-beams are produced by the hot-rolled method, which cannot be said about channel bars.... In addition to this technique, GOST allows the manufacture of channel profiles by bending blanks. Hot-rolled production of channels involves heating the material to a high temperature using special equipment, followed by shaping the billet into the required shape. Bent elements are made in a cold way, bending the edges of the sheets at the desired angle.

If we compare both materials in terms of price, then the channel will be more expensive, since it is heavier. I-beams are lightweight per linear meter, so the profile is popular in many areas.

The comment was sent successfully.