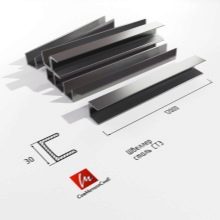

Features of channels 30

Channel 30, along with 40 and dozens of other denominations, is most often made from simple medium-carbon steels. It is used as the main assembly unit for structures for building and other purposes.

general description

Channel - element with main and side walls. It is subdivided as a type of H-shaped (two-sided-shelf) and ordinary (unidirectional, resembles a truncated letter "P") subspecies. The H-structure is like a mirror image of the U-contour, however, the thickness of the main wall does not double, as with full-fledged mirroring. "Reflection" is not mutually exclusive, but is complemented by a P-construction.

Channel assemblies, operating at a high level of wear, are made of special steel alloys, for example, from 110G13L. So, this alloy is marked by a high level of wear resistance, is able to withstand high-temperature impact and shock-vibration forces of high values. Steel 110G13L belongs to austenitic alloys; it is not used for welding, although it does not crack when released. Linear dynamic compression does not exceed 2.7 mm per meter, it is also heat treated at a temperature of 1075 Celsius.

After hardening, the workpieces can be cooled in oil and water.

Dimensions and weight

Hot-rolled steel channel for general and special purposes is produced along the width of the main wall of 5-40 cm. The width of the side strips is 32-115 mm. The values of these parameters are controlled by Gosstandart 8240-1997. However, according to another GOST, channel 30 is produced as a hot-rolled product (according to Gosstandart 8240-1989). Cold-rolled channel products are manufactured according to a similar standard - 8278-1983.

The slope angle of the shelves is most often the same: it makes no sense to release excessively bent strips, since this loses the load capacity of the products. They approach the characteristics of conventional double-thickness strip steel. Hot-rolled channel is produced most often from steel St3ps, St5 and 09G2S-12. The latter has a slightly higher hardness and elasticity than the classical St-3-St-6 alloys (due to alloying with manganese and silicon in somewhat larger proportions).

Types

The differences between the assortment of this type and rolled products are only in the arrangement of the shelves at a certain angle. Channel 30 is a unit produced in the "P" and "U" modifications. The first means that the side strips of the product are parallel to each other, the second means that they, on the contrary, are bent inward at a slight angle. The classic channel element implies a perpendicular arrangement of the side strips relative to the main one, but in the “U” modification this perpendicularity is violated. Parallelogram channels are produced only for individual orders and in small batches, their shelves are parallel and curved in the same direction.

Such elements do not carry any additional advantages either in strength (elasticity, hardness) or in load resource, therefore the shelves are bent counter-isosceles (along the bend angle). Thus, the denomination of 30U and others, equal to it in execution, appeared. Channels 30P and 30U are produced in the form of hot-rolled (with sharp bends) and cold-rolled (smoother in the corners, bent design).

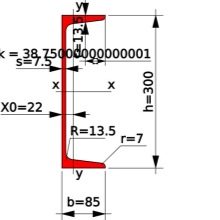

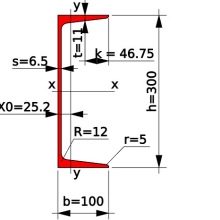

The measured value of the length of one channel unit is 11.75-12 m (coincides, for example, with pins A3 / A500-C). The width of the main wall is 30 centimeters. The denomination number indicates the value in centimeters, not in millimeters. Cold-rolled "thirty" is produced from 3 calm or semi-calm steel.The weight of 1 meter (running) of hot-rolled channel 30U is 31.8 kg, in a ton of rolled steel of this nominal value is 31.45 m. The width of the 30U shelves is 10 cm. The thickness of the main edge is 6.5 with an accuracy of 1 mm, the value for curved shelves is 11 with an accuracy of 1.5 (the error is allowed according to GOST).

The bend radius of the flanges of the cold-formed channel element is no more than 12 mm. At the request of the customer, a twelve-meter element can be cut into pieces of 6, 4, 3 and 2 m (division of a 12-meter unit). Skewing of the side edge is not allowed more than 1.5 ppm from the value of its width, otherwise such unevenness is noticeable to the eye and can cause weakening of the structure. For a channel of 30 nominal, carbon steel alloys with a low or close to average content of alloying impurities are used. Deflection of the main and side strips of channels should not exceed 1 mm based on the total length of the channel unit. The total weight of the channel is calculated based on the specific value for most steels. The specific gravity of steel alloys is 7.85-7.95 t / m3, this value is multiplied by the actual volume of space occupied by the channel element.

Curved channels have equal and unequal flanges. Hot-rolled elements are cast (baked) from scratch, so the angle remains sharp, since the shape that forms sharp corners has already been set, and it is very difficult to bend a sharp corner into a smooth one.

Application

The channel is used for the construction of industrial, office and residential buildings with a structure with significant spans in length. It is used to assemble frames and cases for mechanisms of machine devices, all kinds of special equipment. Channel elements have the ability to withstand significant loads without being destroyed. Such are, for example, products made of semi-calm 6 steel grade St. Even when the load slightly exceeded the calculated ratings, even if the bending of the products down occurs, it is insignificant: only the master will notice it by eye, standing up from the end of the ceiling for a detailed view.

However, repetitive alternating loads with a high frequency will lead to the accumulation of fatigue stresses in the product. Microcracking, as a rule, occurs long before the complete exhaustion of the product resource. You can recognize the proximity of a structure to a breakage, say, by knocking on it: an ideal solid steel rings, and does not emit a dull sound, the frequency response of which is significantly distorted when a sound wave is transmitted through the thickness of the material. One of the typical applications of the channel is support poles and towers of power lines and cellular networks.

It is relatively easy to weld and screw on a high support using channels, angles and fittings with a professional pipe.

The comment was sent successfully.