Choosing a machine for a chain-link mesh

The chain-link mesh is widely used on the farm. Of course, most often fences are made from it or used in construction. The great demand for this material opens up opportunities for those who want to produce such a mesh not only for themselves, but also for sale. To do this, you only need to select a machine and high-quality raw materials.

Types of machines

Equipment for knitting mesh-chain-link is represented by a large number of machines. They differ in type, and sometimes it is not easy to choose the right one. When choosing, an important condition is the quality of the machines, which will make it possible to make a good chain-link. The weaving process should be easy to operate and highly manufacturable. The chain-link mesh is made on various types of machines.

Manual option

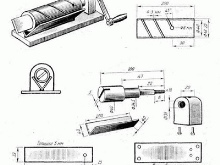

Suitable for weaving mesh at home. In order for this equipment to work, the constant participation of the worker is required. This makes the process unprofitable and time-consuming. As a rule, such a machine has a manual drive. Among the differences, it is worth noting the small size. For a manual unit, 3 square meters are enough. You have to wind and braid the spirals of the mesh with your hands. Such a machine consists of a strong supporting frame for fastening the working units (bed), a working element responsible for winding the mesh (auger), a drive lever, a gearbox, and guide rollers. These machines are not used commercially as they require the constant presence and intervention of the worker to operate. As a result, the process turns out to be unprofitable from an economic point of view and time-consuming.

Using a manual setting, you can make spirals from wire with a diameter of 1.5-6 mm. The cell size can vary from 0.3 to 0.6 in. This parameter depends on the different augers. Subject to experience in one shift, you can make 50-60 meters of chain-link fabric. It is difficult to produce commercial mesh on such a machine, and the machine has a short service life. On a manual unit, you can make a sufficient amount of chain-link to create some kind of fence (for a site around the house). A large number of units of this type are offered for sale, but among them the BMP brand stands out. Its features are simple design and fault tolerance.

In addition, the machine can be operated even without special skills.

Semiautomatic device

The semiautomatic device combines wide functionality and compact dimensions at the same time. Such a device is suitable for weaving mesh even in the garage. The cost of the unit starts from 45,000-50,000 rubles. A person must necessarily work on semi-automatic equipment, since some processes are manual. For example, this includes the folding of the mesh. The disadvantages of the device include inaccuracies associated with the human factor present. Most often, such machines are stationary and are distinguished by their significant weight and good performance. It is best to place them on 10 square meters. m, in a place where there is constant power supply.

Wire feeding and cutting as well as web weaving are carried out mechanically. The level of performance of such devices is sufficient for the average commercial production. Moreover, the quality of the mesh on the semi-automatic equipment is better than on the manual device. For a shift using such a unit, it is possible to produce from 120 to 160 running meters of mesh. A distinction is made between devices that do not have a control module (PS) and with a control unit (PS-A).Among the most popular options, PSR-2 is known, which works with a wire with a diameter of 0.1-0.3 cm. It produces a mesh with cells of 0.2-0.6 dm. In this case, the width of the canvas will be about two meters.

Machine

The machine is perfect for mass production of high quality chain-link. When working with such a device, the operator only loads the tray with raw materials, and then removes the finished roll. The automatic unit is highly efficient. In an hour, he is able to create 100-120 sq. m of mesh-netting. You can place such a device on an area of 15 square meters. m. When using the equipment, it is important to observe that the operating modes are performed correctly, and the machine is in good working order. The machine automatically curls spirals, weaves mesh cells, bends the ends and even rolls them into rolls.

Wire with a diameter of 0.8-6 mm can be used as raw material. In this case, the cell size can be obtained up to 8 cm, and the width of the web - 20-250 cm. Due to a good control system, one employee is enough to operate several automatic machines at once. In such installations, all parts are of high quality and reliability. The working resource of the units reaches 15-20 km of track.

It should be noted that the system automatically lubricates the wire, which reduces bending forces and increases the durability of the chain-link. Automatic devices are capable of working with different wires.

Top Models

The rating of machine tools showed that among the whole variety, three models stand out especially.

ACR15 / 2

In the first place is the ACP15 / 2 machine, which is distinguished by simple settings and controls. He makes small quantities of netting. Due to the low noise, any place is suitable for installation, even near residential buildings. Without an operator, the unit is able to independently bend the ends of the mesh, wind the web, cut and stop. As for all other processes, they are performed by a person. At the exit from the machine, a mesh with a mesh of 18-50 mm and a height of 2-3 meters is obtained. For knitting, wire is used in one thread. Moreover, it can have a polymer coating or be unevenly rigid.

Among the advantages of the device, it is necessary to highlight the gear motor as a whole, as well as the improved cooling system due to the emulsion pump. Guide bushings serve for a very long time and without failures, as they are coated with special hard alloys. When the unit is forced to stop, the program settings specified earlier are not lost.

SPA 01-04

The second place went to a knitting machine called SPA 01-04. This machine creates a mesh with a mesh of 2-6 cm. Conveniently, one millimeter thick galvanized wire is suitable as a starting material. The unit works completely independently. The operator only prepares the work template in advance, as well as supplies the initial and removes the finished materials from the unit.

The device automatically unwinds the wire, weaves a chain-link, bending the ends on each of the cells. At the end of weaving, the finished fabric is rolled into a roll. If material becomes entangled at one of the stages of the device's operation, it will stop automatically. Conveniently, the unit is equipped with high-quality cooling to avoid overheating. The device is capable of producing 65-180 sq. meters of chain-link. If desired, the machine can be supplemented with special devices that allow the net to be wound on a separate coil. It is convenient that the unit can bend the ends of the chain-link on both sides.

All these models have a built-in controller that can be programmed.

BCA-97

The BCA-97 model also entered the top of the best chain-link weaving machines. With this device, you can get a canvas with a mesh of 10-60 mm and a width of 50-200 cm. Among the advantages of the unit, users note the universal design of the passage elements, which allows the use of any wire.Machine repairs can be carried out using simple car parts. You can find the latter in any specialized store, which are even in small towns.

To install the machine, you will need approximately 20 square meters of floor space. One operator will be able to work simultaneously with three such devices. The quality of the wire directly affects productivity. For example, with a stable feedstock, the machine can produce 50 square meters per hour. m of canvas with a cell of 50 mm. Also, many people like that the device is easy to configure and at the same time performs all the functions automatically.

Selection Tips

When choosing an apparatus for creating a chain-link mesh, it is important to decide for what purpose it is needed. If for home use, when the mesh must be produced in small quantities, then a manual unit is sufficient. It is worth noting that its performance will be quite low. For production, it is better to choose at least a semi-automatic machine. It is only desirable that its size be small. It is important that such a device allows adjusting the dimensions of the blade, the direction of the knife and the speed at which it rotates.

For the manufacture of significant volumes of mesh and with minimal intervention of the worker, only an automated version of the machine is suitable. However, such devices are most often purchased by large enterprises. In terms of productivity, these units replace three semi-automatic machines. Of course, the cost of one automatic machine is equal to the cost of five semi-automatic machines.

At the same time, it is important to take into account that a person must work at each non-automatic unit, who will have to pay.

In the next video, you will find an overview of the machine for the production of a chain-link mesh (automatic CA-2 with coiling of a roll into a compact).

The comment was sent successfully.