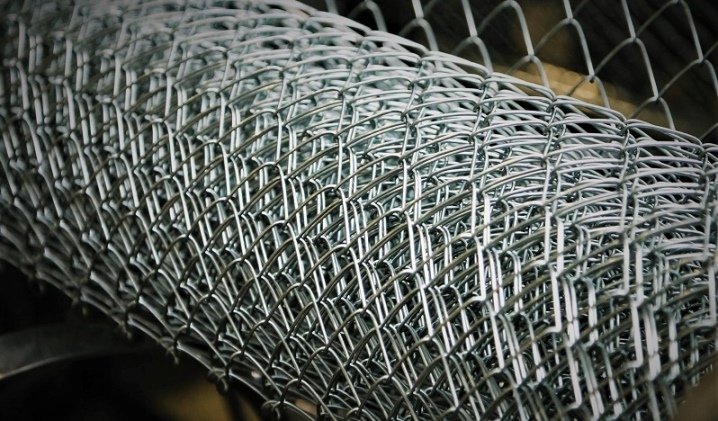

What is a chain-link mesh and how to choose it?

The netting-netting is one of the most popular materials for the manufacture of fences and enclosures for dogs, temporary hedges. Other areas of application are also found for it. The fabric is produced in accordance with GOST, which determines what kind of wire is needed for manufacturing. A detailed overview of this material, its features and installation methods will help to understand all the variety of mesh types.

What it is?

The material known today as the netting was invented in the 19th century. This name refers to all modern types of structures, woven from a single metal wire. In the USSR, the material was first standardized in 1967. But long before the chain-link mesh appeared in Russia, such products were used in European countries. German Karl Rabitz is considered to be the inventor of the woven mesh. It was he who, in 1878, filed a patent for a machine designed for the production of such products. But in the documentation for the invention, a fabric mesh was indicated as a sample. Nevertheless, the name Rabitz eventually became the name of a structural material.

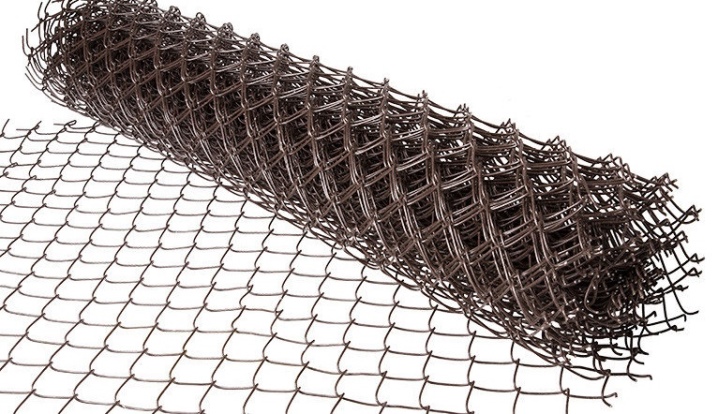

Simultaneously with the German specialist, similar surveys were carried out by engineers in other countries. The hexagonal wire mesh machine is known to have been patented in the UK. But officially, such material began to be released in 1872 in the United States. The netting type chain-link has its own characteristics. One of the main ones is the tetrahedral (diamond-shaped or square) type of cell, which distinguishes the material from all others.

Features of production

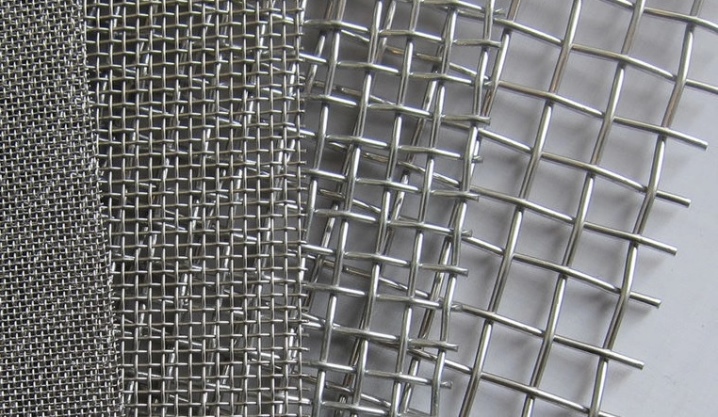

The production of the chain-link mesh is carried out on machines that are quite simple in their design. The manufacturing process involves screwing the spiral wire base in pairs, one into the other. Weaving on an industrial scale is carried out on high-performance machines capable of forming fabrics of considerable length. The raw materials used are mainly carbon steel products, less often - aluminum or stainless steel.

The wire may not have a protective coating or undergo galvanizing, polymerization.

Main characteristics

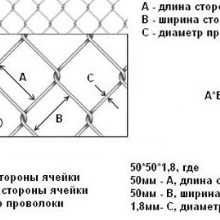

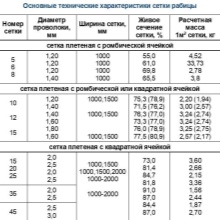

The chain-link mesh in its standard version is produced according to GOST 5336-80. It is this standard that determines what kind of indicators the material will have. The diameter of the wire used ranges from 1.2 to 5 mm. The standard width of the finished mesh fabric can be:

- 1m;

- 1.5 m;

- 2 m;

- 2.5 m;

- 3m.

Chain-link meshes are made of spirals in 1 wire. The standard roll weight does not exceed 80 kg, coarse-mesh versions can weigh up to 250 kg. The length is usually 10 m, sometimes up to 18 m. The weight of 1 m2 depends on the diameter of the wire, the size of the cell, the presence of a zinc coating.

Applications

The areas of use of the mesh-netting are quite diverse. It is used in construction and repair, as a main or auxiliary material, and is used in landscape design. Among the most popular areas are the following.

- Construction of fences... Fences are made of mesh - temporary or permanent, gates, wickets. Depending on the size of the cells, you can change the degree of light transmission of the fence.

- Screening of materials. For these purposes, fine-mesh nets are used.Screening is used to separate materials into fractions, remove coarse debris and foreign matter.

- Creation of pens for animals... From the chain-link, you can build an aviary for dogs or make a chicken coop with a summer range.

- Landscape design... With the help of a grid, you can arrange a front garden, separating it from the rest of the site, frame a perimeter with a hedge. The nets are used for vertical gardening - as supports for climbing plants, they strengthen crumbling soil or rocky slopes.

- Mining trades... Here the workings are fastened with a chain-link.

- Construction works... Meshes are used for thermal insulation of buildings and structures, as well as in the process of applying plaster mixtures.

These are the main directions in which the chain-link is in demand. It is also used in other areas, used in the reinforcement of glass or other brittle materials that require strengthening.

Views

There are many options for the netting being produced today. The easiest way is to classify it according to the following criteria.

- By release form... Most often, the netting is supplied in rolls - ordinary or tightly wound with a smaller diameter. For fences, it can be realized with ready-made sections, already stretched over a metal frame.

- By the shape of the cells... Only 2 types of products are produced - with square and diamond-shaped cells.

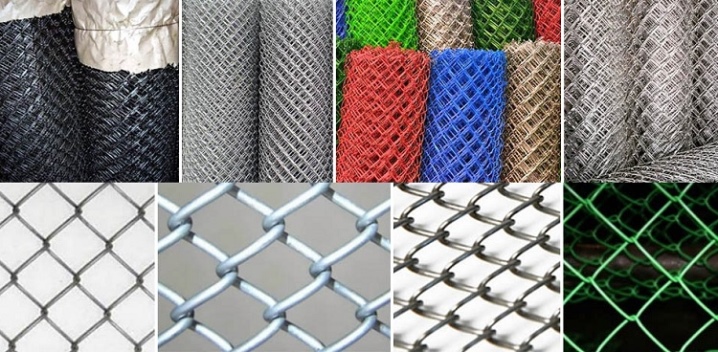

- Coverage availability... The chain-link mesh is usual - without additional protection against corrosion, it is usually painted. Coated meshes are divided into galvanized and polymerized. The second option most often has colored insulation - black, green, red, gray. Such nets are better protected from the influence of external factors and are suitable for use as an element of landscape decoration.

- By cell size. The fine mesh allows less light to pass through, but has maximum strength and withstands significant operational loads. Large is used only in construction, as an element of the fence.

These are the main features by which a mesh can be classified. In addition, the type of metal from which it is made matters.

Materials (edit)

The first patents for the chain-link involved the use of exclusively metal wire in the manufacture of products. But modern sellers also offer fully polymer products under this name. Most often they are made on a PVC basis. According to GOST, only a metal base should be used in production. It can be made from different metals.

- Black steel... It can be normal - this is used in most products, as well as low-carbon, for lightweight products. The coating of such nets is usually not provided, which limits their service life to 2-3 years.

- Cink Steel. Such products are well protected against corrosion, thanks to the outer stainless steel coating of the wire, they can be used in environments with high levels of humidity or mineral deposits.

- Stainless steel... These nets are heavier, but have an unlimited service life. The composition of the wire is selected taking into account the operating conditions. Products are usually produced in limited quantities, according to individual orders.

- Aluminum... A rare option, but it is also in demand in a narrow list of areas of activity. Such meshes are very lightweight, not subject to corrosive changes, but more vulnerable to deformation and other damage.

These are the main materials used in the production of chain-link. Polymerized products can have a base of black or galvanized steel, depending on the purpose of the material, its operating conditions.

Top manufacturers

Today in Russia, more than 50 enterprises in the sphere of small, medium and large businesses are engaged in the production of nets of the chain-link type. There are many manufacturers among them that deserve attention.

- "Constant" - factory of nets.An enterprise from Novosibirsk specializes in a chain-link made of black steel - galvanized and uncoated. Deliveries have been established far beyond the region.

- ZMS... The plant from Belgorod is one of the largest suppliers of chain-link in the Russian market. The company carries out a full production cycle, standardizes products in accordance with current regulations.

- MetizInvest. A manufacturer from Oryol makes wicker nets in accordance with GOST, provides sufficient supply volumes throughout Russia.

- "PROMSET"... The plant from Kazan provides many construction companies of the Republic of Tatarstan with the netting. The range of products includes steel and galvanized materials in rolls.

- "Omsk Mesh Plant"... An enterprise that manufactures products for the domestic market. Works in accordance with GOST.

There are also factories in this profile in Irkutsk and Moscow, in Yaroslavl and Kirovo-Chepetsk. Local products are usually more affordable.

Secrets of choice

Mesh-chain-link is a material on sale in a wide range. You can find a colored and galvanized version, take an option with a larger or smaller cell. It's just that it can be quite difficult to understand which version is best suited for specific needs. Some features of woven nets are important to consider when choosing so that the further use of the material does not cause inconvenience.

- Dimensions (edit)... For the fence or fence of the front garden, grids up to 1.5 m wide are suitable. Larger-format options are used in industry, mining, in the construction of corrals for animals and poultry. The standard roll length is 10 m, but it can be 5 or 3 m, depending on the thickness of the wire, the width of the material. This is worth paying attention to when calculating.

- Strength... It directly depends on the thickness of the metal wire. Most often, a material with a diameter of at least 2-3 mm is used. If we are talking about a galvanized or polymerized variety, it is worth taking the option with a thickened base, since a protective coating is applied over it. With equal diameters, the thickness of the steel in a conventional mesh will be higher.

- Cell size... It all depends on the purposes for which the mesh is purchased. Fences and other fences are usually made of material with cells ranging from 25x25 to 50x50 mm.

- Material... The service life of the mesh directly depends on the presence of a protective coating, such as metal. Most often we are talking about choosing between a galvanized and ordinary chain-link. The first option is good for permanent fences, retains its properties for up to 10 years. The black metal mesh will require regular painting or will deteriorate from rust in 2-3 seasons.

- Compliance with GOST requirements. It is these products that undergo complete quality control. It is also worth checking the correctness of the packaging, the accuracy of the geometry of the rhombuses or squares. Traces of rust and other signs of corrosion are not allowed.

When choosing a chain-link, it is imperative to study the marking on the accompanying documentation. The exact parameters of the roll, the thickness of the wire, the type of metal are indicated here. This information will be useful when calculating purchase volumes, planning loads on a fence or other structure.

The nuances of installation and painting

The mesh-netting is one of the most popular materials for quick installation of structures. Installing it as a framing for a hedge or fence is straightforward, even for builders with minimal experience. It is enough just to prepare the place by removing excess vegetation or debris. You will also have to pre-calculate the number of support pillars, dig in or concrete them, and then pull the mesh. When performing work, it is worth considering important recommendations.

- You need to pull the chain-link from 1 post from the corner of the site or from the gate. The roll is installed vertically, the rolled edge of the net is fixed on welded hooks. It is attached to concrete or wooden posts with steel wire.

- Tensioning is performed at a distance of 100-150 mm from the ground surface... This is necessary to prevent corrosion.

- The web is completely unwound. It is important to calculate the position of the posts so that the end of the roll falls on the support. If this cannot be ensured, it is worthwhile to connect the individual elements of the sections even before tension, by unwinding the wire along one of the edges.

- At the end of the work, the support pillars are covered with plugs.

Fences and other structures made of chain-link can hardly be called aesthetic. They do not allow for the proper degree of privacy of private life. In the fight against this, summer residents often come up with a variety of tricks - from planting climbing plants on a fence to hanging a camouflage net.

It is also possible to improve the overall aesthetics of ferrous metal mesh. To do this, paint it quickly enough, at the same time protecting it from corrosion. You can use fast-drying acrylic compounds or classic oil, alkyd mixtures. They can be applied in the classical way - with a roller or brush, spray gun. The denser and smoother the coating is, the better. The mesh already having traces of corrosion is preliminarily smoothed with sandpaper.

The comment was sent successfully.