Characteristics of the plastic mesh-netting and its fastening

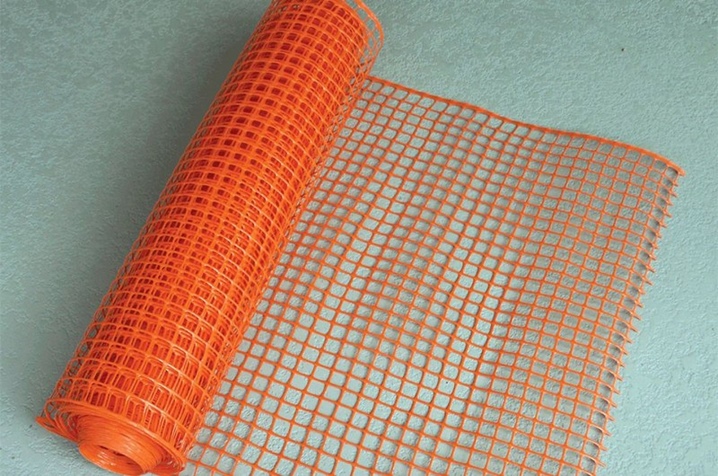

The plastic mesh-netting is very popular among the owners of summer cottages and backyards. With this in mind, manufacturers offer a variety of colors, sizes and designs of this material. It is worth talking in more detail about which lamellas and corners are suitable for attaching the mesh-netting, what is the difference between the green version with PVC-coating for the fence and the white plastic one, what other options are there.

Peculiarities

Plastic mesh-netting is a relatively new material in the construction market. It is used to organize a fence on an ongoing basis, as well as for zoning a site. A garden fence of this type compares favorably with analogs made of metal materials, wood. The use of plastic mesh for fences avoids their destruction under the influence of atmospheric factors.

Consider the main operational characteristics and features of the material.

- Light weight. A running meter of mesh has a weight of up to 200 g, the whole roll - up to 8 kg.

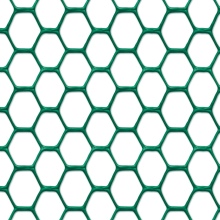

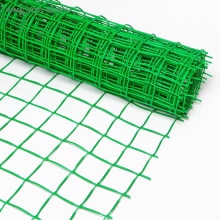

- Diverse cell shape. It can be diamond-shaped, rounded, in the form of honeycombs, squares, rectangles.

- Color spectrum. The most popular are green, white, blue, red, gray nets, as well as more complex camouflage colors.

- Lifetime. He reaches 40 years old.

- Lack of complicated care. It is enough to rinse the material with water from a hose to put it in order.

- Heat resistance. The plastic mesh can withstand operation at temperatures down to -50 degrees and heating up to +80. And also the material does not fade, retains its original temperature in the sun.

- Ease of installation. Thanks to the manufactured accessories, you can easily do the installation yourself.

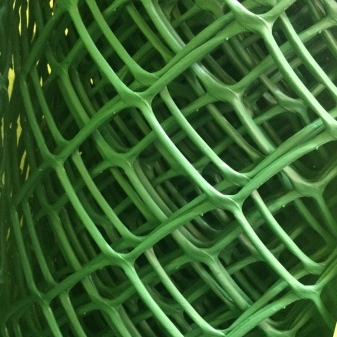

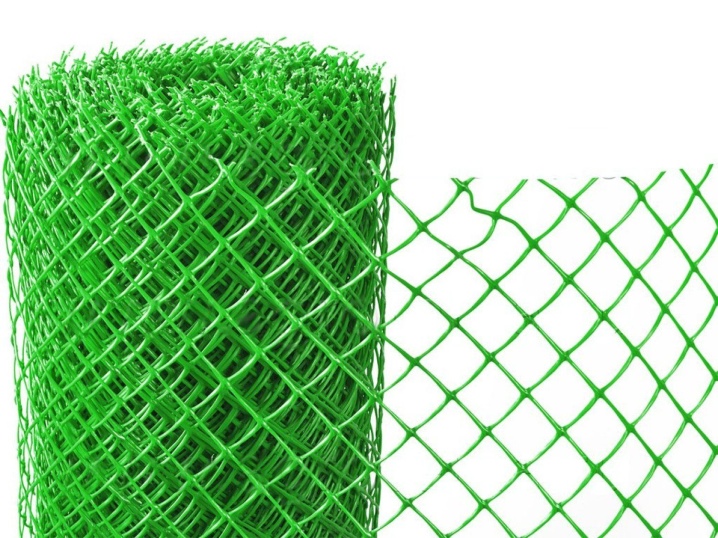

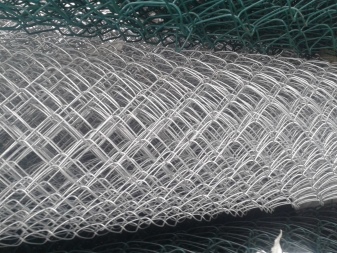

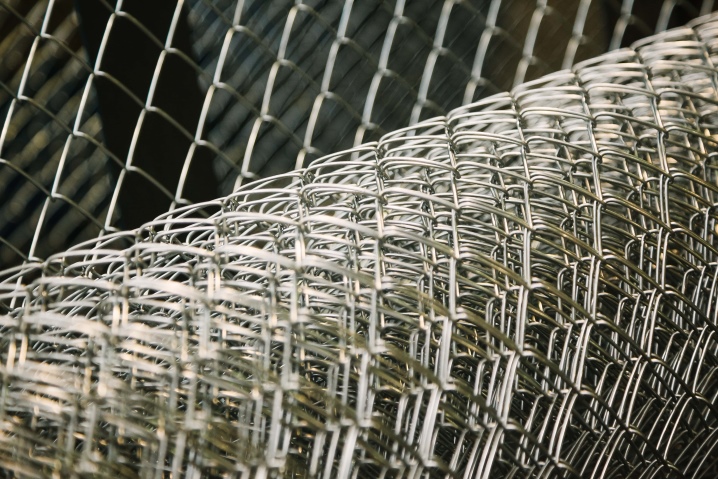

By its design, the plastic mesh is divided into completely polymer and metal with a PVC coating - the so-called plasticized. In terms of its parameters, it is completely similar to galvanized steel, but it is better protected from the influence of atmospheric factors. The PVC braid can have different colors, it is mounted in the same way as the classic options, it looks presentable.

With such a fence, the site is well protected from the penetration of strangers, this option can be used for zoning the territory, as a basis for vertical gardening.

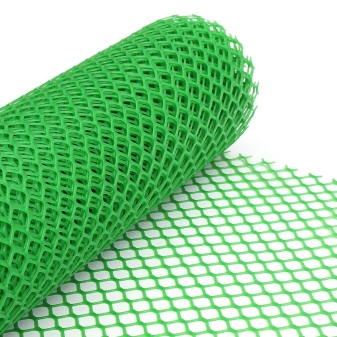

Completely plastic nets are also quite in demand by summer residents and owners of garden plots. They are made from extruded polymeric materials that are first stretched into fibers and then woven into the desired range of meshes. Coloring is done in bulk, which avoids color unevenness. The net is produced in rolls up to 100 m long, the width varies in the range of 1-2.5 m.

There are several varieties of polymer-based products at once.

- Garden mesh. This is a universal option for zoning the territory of a garden plot. It is distinguished by an increased level of rigidity, has cells with a section of 20x20 or 10x10 mm. The material is used as a lattice for climbing and climbing plants, as a fence for lawns and flower beds.

- Decorative fencing. These types of plastic mesh-netting are characterized by a variety of cell shapes, most often round, rectangular and "honeycomb" options. Sometimes cells are combined.The main difference from other types of this fence can be called the embossed surface of the material, combined with an improved ability to withstand aggressive UV radiation.

- Rabitz. The all-plastic construction is made of PVC with or without reinforcement, the weave looks similar to that of metal. Fences made of such a mesh have an average degree of rigidity and withstand operational loads well. The size of the cells can be from 55 to 18 mm, they are always diamond-shaped. In terms of external characteristics, this type of mesh is the simplest, no frills.

- Emergency net. This type of product is distinguished by high strength characteristics and is able to withstand significant shock loads. The color scheme of such meshes is the most diverse - they are often painted in bright, well-visible shades. Such structures are installed as fencing on the territory of construction and sports grounds, separating sectors during concert and entertainment and other public events.

- For shading. This version of the mesh can act as an independent fence or an auxiliary element as part of other types of fence structures. Its distinguishing feature is its ability to shade space. This indicator varies in the range from 35 to 100%, but the structure itself does not have stiffening ribs, its strength is minimal.

Plastic mesh-netting have the widest application. They are used for fencing sports and construction sites, children's playgrounds. In the dacha sector or on a personal plot, they are installed as part of stationary and temporary fence structures.

You can use such fences in the frame of lawns or corrals for small farm animals.

Top manufacturers

A galvanized mesh-netting in a PVC sheath or a classic plastic lattice is an excellent solution for creating temporary and permanent fences. White, green, red - it is produced by dozens of manufacturers in Russia and abroad. It is worth finding out in more detail about which companies produce material with and without braiding in order to avoid possible mistakes.

Several brands can be distinguished among the leading companies in the plastic fence mesh market.

- "LEPSE". Russian company specializing in the production of chain-link of various types. In addition to metal options, the plant also has a line of polymer nets. The company also sells accessories for installation.

- Conwed Plastics. Sales leader among foreign companies. The brand manufactures products at its own factories in the USA and Belgium. The nets meet the requirements of European standardization systems, the polymer fabric is flexible, elastic, and can withstand significant loads. The brand's products are distinguished by their aesthetics.

- TPK Polistren LLC. The mesh has been produced under the Stren brand since 2006. The company is considered a recognized market leader, cooperates with many large construction companies and agricultural producers.

- Tenax. The Italian manufacturer produces biaxially oriented mesh made of high quality polymeric materials. All products comply with European standards, the line includes a wide range of sizes and many color options.

Other well-known companies include Tenser from the USA, Russian SpiderNet, Slavros, SlavPlast. The last three brands offer original decorative weaving options and products with non-standard designs.

Selection Tips

The variety of plastic nets on the market makes it somewhat difficult to choose the right option. To facilitate decision-making, it is worthwhile to determine the basic requirements for the fence from the very beginning. Will it be solid or partial, decorative or functional, only the owner himself decides. Besides, the budget for the purchase is of great importance: prices vary from 60-70 rubles. / m2 up to 140 rubles./ m2, foreign-made products are more expensive.

Here are the basic guidelines for choosing.

- Appointment. If there are animals on the site that are capable of escape, small children who can lean on the fence with all their weight, it is better to immediately choose the emergency option. It will withstand maximum loads without deformation. For installation between the sites of neighbors, an ordinary chain-link is suitable; for the facade, it is better to choose a lattice that easily turns into a hedge.

- Cell size. It is also directly related to the purpose of the fence. To protect the territory from any unauthorized intrusion, a fine-mesh mesh is suitable. For decorative fencing, options with parameters 10x10 or 20x20 mm are more suitable for each weave. This parameter also affects the light transmission - the smaller the cells, the more shadows will be.

- Appearance. Meshes with an original design are well suited for creating façade fencing. Here, the unusual shape of the cells or their variable cross-section looks original and catchy. To cut off the territory from the neighboring site, you can choose a simple chain-link or an emergency option. If you want to combine the mesh with a hedge, it is better to make a sectional fence that can withstand such loads.

- Material. One-piece plastic mesh has significantly lower bearing capacity than metal mesh with polymer braiding. If you have a choice, you should give preference to environmentally friendly and durable PVC.

These are the main selection criteria. Besides, it is worth paying attention to characteristics such as the height and thickness of the mesh. Today fences of 2-2.5 m with rather strong and thick cells are popular. To make the fence difficult to cut or break, you can choose the metal-reinforced option.

How to fix the mesh?

Plastic fence installation requires compliance with certain rules during installation. Special slats, corners, strips help to fix the structure. In this case, the pillars are also often chosen from polymeric materials, since the load on the surface is not too high. The procedure includes a number of steps.

- Territory marking. It is necessary to determine the perimeter of the future fence, mark the location of the pillars. It is worth considering the length of the roll. If it is 15-18 m, the supports are placed every 3 m.In other cases, every 2-2.5 m.

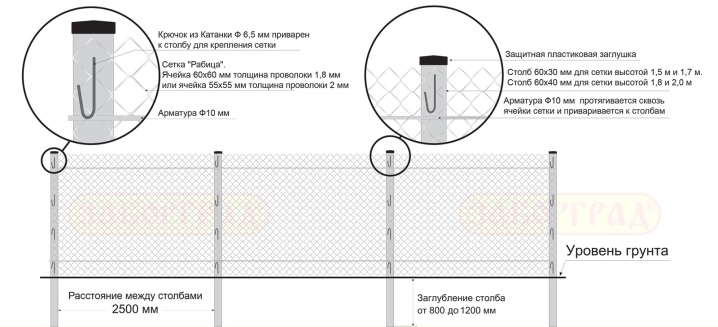

- Installation of pillars. For a capital structure, it is better to take metal, with a diameter of 50-100 mm, holes for them are dug 80 cm deep.First, corner posts are mounted, leveled from the ground, then control marks are pulled along them and the remaining points are marked with a plumb line. The installed supports are backed up with stone or broken brick, concreted.

- Hanging the net. It is pulled from the corner, secured with polymer clamps. Having hung the extreme section, you can move on to the next support, trying to stretch the canvas as much as possible. You can cut out the material, trim its edge with an ordinary pruner or scissors. If several rolls are used, at the junction for 1 post 2 parts of the canvas will be held at once.

When it is planned to make a sectional fence, in the process of work it will be necessary to make a frame from a bar. Installation is carried out from the inside, on brackets. The mesh is also fixed from the seamy side with small nails or special strips in the corners. Special fasteners are made under the sections on the pillars, depending on the mass, they are hung on self-tapping screws or bolts. The frame can be quite light as the loads from the mesh are low.

Given these recommendations, you can easily cope with the self-installation of a fence made of a plastic mesh-netting. With a minimum of tools and a small investment of time, the created fencing will successfully maintain an attractive appearance for many years.

You can see what kind of plastic mesh-netting to choose as a fence for your site in the next video.

The comment was sent successfully.