How and how to glue polycarbonate?

Polycarbonate is one of the most common and commonly used building materials. It is considered a fairly new raw material, from which greenhouses, both large and small, are made, livestock complexes, gazebos, fences and other structures. For their installation, metal, glass or film were previously used.

Polycarbonate, like any other building material, is subjected to certain seasonal loads (snow) during operation, which lead to deformations, cracks, and splits. In such cases, it is necessary to take repair measures, namely to glue the material.

Types of glue

Polycarbonate belongs to strong, reliable, durable, innovative materials, it is widely used today in various fields of human activity.

Polycarbonate is characterized by transparency, wide assortment, and availability. But even despite a number of advantages and features, it happens that the material requires urgent repair.

There are several reasons that can lead to deformation of polycarbonate, namely:

- wrong choice in thickness;

- errors were made during the installation process;

- exceeding the permissible load.

Whatever the reason for the appearance of cracks on the polycarbonate, there is only one way out - to glue the material using special glue for this. Currently, there are many types of adhesives and adhesives that can be used during renovation work.

In practice, two types of repair glue are used.

- One-component - contains one substance. This option is preferable when gluing a simple product, which will not be subject to a large load. Using one-component glue during installation or repair, a polycarbonate sheet can be glued to rubber, plastic, metal, as well as an identical material. The connection is very strong, reliable, resistant to temperature changes and precipitation.

- Multicomponent - the composition contains several effective ingredients. This glue is used only if a heavy load is constantly applied to the polycarbonate structural parts. The connection is characterized by a high degree of strength and reliability.

There are 4 types of glue, depending on the predominant substance in the composition.

- Polyurethane. The most reliable and high quality gluing. It guarantees the chemical, mechanical and thermal strength of the finished joint. Also a distinctive feature is that the seam is transparent. Most often, professionals use polyurethane glue in their work, since it is quite difficult for them to glue polycarbonate.

- Silicone. Provides a reliable seam, resistance to various weather conditions and mechanical stress. It comes in different colors: white, black and gray. It follows from this that the seam will be noticeable in any case.

- Ethylene vinyl acetate. It is the easiest and most primitive glue to use. The polycarbonate connected by it, most likely, will not last long: the seam will not withstand a heavy load.

- Acrylic. Suitable for gluing a flat sheet. With its help, polycarbonate can be glued to glass, mirrors and other furniture elements.

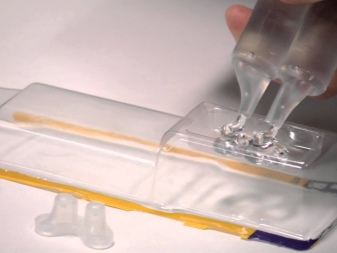

There is another type of adhesive that belongs to two-component - hot hardening glue.

It is ideal for repairing oversized polycarbonate sheets.To work with such glue, you need a special gun that converts a solid into a liquid state.

The most reliable and preferred is a polyamide-based hot curing adhesive.

Bonding process

Many today are wondering whether it is possible to glue polycarbonate sheets together at home using special adhesives. Of course you can - and even more! With your own hand, knowing the specifics of the work and using the right glue, you will be able to glue polycarbonate to iron, wood, aluminum and other materials.

The process consists of 4 stages.

- The first step is to decide on the gluing method. Polycarbonate can be glued either overlap or end-to-end. The first method is relevant if it is necessary to ensure maximum strength and high reliability of the seam. The method of gluing structural parts joint to joint can be used only if high load and mechanical stress are not provided.

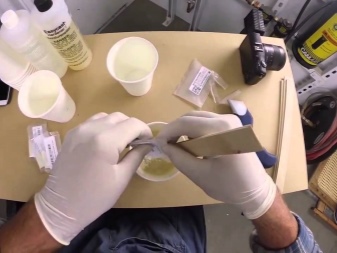

- It is good to clean the work surface from dust and dirt. Experts also recommend treating the surface of materials with a special compound before gluing. This will allow the glue to adhere well and quickly.

- Prepare the tools you may need.

- Apply glue using a special glue gun to the edges, cuts. The ends of the materials must be especially well glue-treated.

The adhesion time depends on the chemical composition and characteristics of each glue individually.

When gluing polycarbonate with a material of a different type and structure, it is advisable to use, in addition to glue, also a special double-sided tape. The use of tape is important if you need to connect two flat surfaces. The connection itself will be more durable and reliable.

Tips & Tricks

In order for the connection to meet all the requirements, to be of high quality, reliable, durable and withstand high loads, it is necessary to adhere to important recommendations during the repair process.

- When choosing an adhesive for repair, carefully study its composition and purpose. Each manufacturer is obliged to indicate the technical parameters and material properties.

- If cracks or any other type of deformation has formed on the monolithic polycarbonate, silicone or polyurethane-based glue can be used for repair. To repair cellular polycarbonate, it is desirable to use a composition with a polymer.

- Do not buy glue that contains a solvent.

- Use a special glue gun during the repair process. This attribute will not only speed up the gluing, but also make the seam better and more accurate.

Of course, the most important thing is to take into account the purpose of the structure to be repaired and the load that it can withstand.

It is also best to give preference to reliable and well-known glue manufacturers who can confirm the quality of the products by the availability of certificates.

Don't forget about personal protective equipment. It is best to work with gloves and a respirator to protect the respiratory system from harmful glue fumes. This is especially important if you are using hot curing glue.

If you doubt the success or are afraid to completely destroy the structure, it is best to contact a specialist.

How and how to glue polycarbonate, see below.

The comment was sent successfully.