How to transport polycarbonate?

Polymer plastic is a very popular, but at the same time rather fragile building material. If incorrectly transported, polycarbonate can be hopelessly damaged. Knowing some of the nuances of material transportation, you will cope with this task without unnecessary problems.

How to download?

To transport polycarbonate on a passenger car, you need to free up space in the cabin. Fold down the rear seats so that the free space is at least 60 cm wide and at least 215 cm long - from the windshield to the tailgate. In the resulting cargo opening, 4 thin sheets of 4 mm polycarbonate or one thick sheet of 6 mm are placed. The trunk door must be secured, because while driving, it can fall and break the canvas.

If it is not possible to clear the opening in the car, you should try to load the material from above. The maximum load on the roof of the car is 100 kg.

It is necessary to take into account the weight of the canvas and limit the number of transported sheets of polymer plastic. For example, in the case of a thin 4mm honeycomb material, it is best to immerse a roll of 8 sheets. Each sheet weighs 9 kg, which together equals 72 kg. In addition, the material rolls up quite tightly, so you have to immerse and unload the polycarbonate sheets in one roll. It is recommended not to do it alone, because the material is fragile and easily damaged.

After loading, the material must be securely fastened with enough ropes and ties to prevent the roll from turning and spinning. It is important not to forget that polymer plastic is fragile and must be handled with care. It is also necessary to take into account that there is a lot of wind load on the trunk. To prevent airflow from bending or deforming the inner polycarbonate sheets, secure the roll along the edge with tape.

Roll transportation of polycarbonate over long distances is undesirable.

When twisted, microcracks can form on the canvas, which will lead to a deterioration in the quality of the material.

The nuances of transportation

To transport cellular polycarbonate, it is wise to order delivery in a truck... The body parameters must correspond to the size of the canvas, and the bottom surface must be flat. Plastic must be placed in the machine only horizontally. If the sheet is placed vertically, the material may become unusable even before it arrives at the site - the polycarbonate will warp and the honeycomb will break. Polycarbonate sheets with a thickness of 4 to 8 mm should not protrude outside the body, thicker panels - with a thickness of 10 to 16 mm - can protrude no more than a meter.

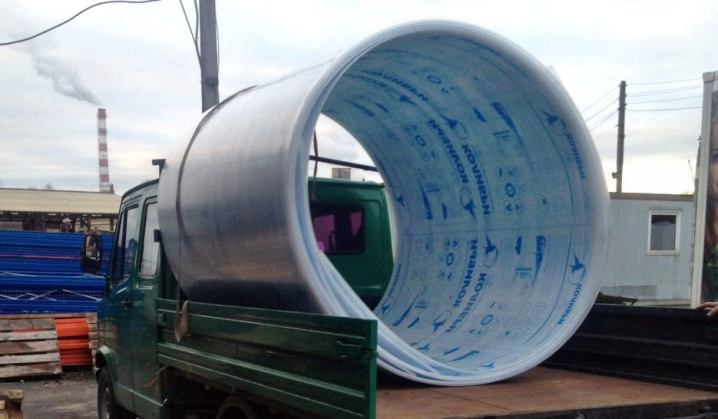

When transporting in a closed lorry body, polymer plastic must be placed rolled up. In this case, the internal dimensions of the body should be larger than the largest diameter of the roll bend.

There is an exception for transportation over short distances - the width inside the body can be 10% less than the allowable bending parameter.

If the transportation will be carried out on the trunk, then the polycarbonate sheets will need to be twisted, for this you need to know the minimum roll radius... For thin panels 4 mm thick, the radius is 80 cm. Thicker panels with a thickness of 8 mm can be rolled with a radius of 90 cm.

Unloading features

Before unloading, it is necessary to prepare a place for storing polycarbonate. This surface must be flat and clean, and all small debris must be removed.You should also cover the storage area with plastic wrap or cloth.

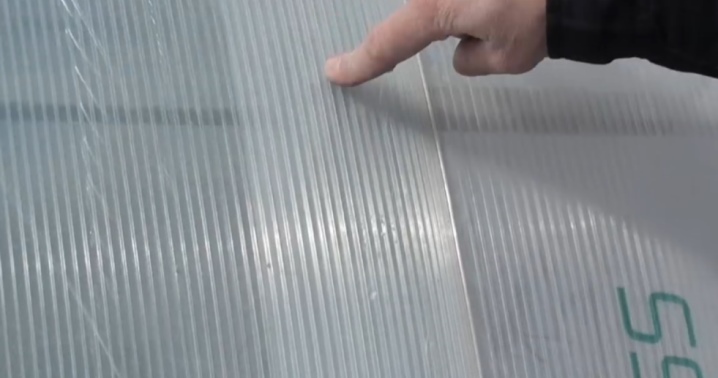

Polycarbonate has a special protective layer of polyethylene, it must never be removed during unloading. - this could damage the integrity of the material. Minor damages such as scratches or dents can spoil the original quality and properties of the plastic.

Now you can start unloading the polycarbonate from the car. Thin sheets can be transported in a stack, but no more than 5 pieces, and thick sheets only one at a time.

It is necessary to pull out the material without unnecessary haste and fuss. Gently shake the sheet so that an air gap separates it from the general stack. It is necessary to take out polycarbonate by the edge, if you take it in the center or from the side, you can break the integrity of the sheet.

If polymer plastic was transported rolled up, after arriving at the destination, the rolls must be carefully unloaded, unrolled and carefully aligned.

The comment was sent successfully.