Varieties of tapes for polycarbonate and their application

Construction is a rather complicated and complex process. For it to be as effective as possible, you need to use a variety of materials. One of the most important building materials is polycarbonate tape. You should know what types of material exist, as well as what they are used for.

Description and purpose

Polycarbonate tape is a material that is used to protect the ends of sheet material during the construction and construction of various structures. Thanks to the use of such a tape, it is possible to increase the service life of the building. A large number of varieties of these tapes can be found on the market today. In addition, the material is available in different sizes, therefore, it is suitable for different purposes. The distinctive characteristics of the material include several of its most important properties:

- the presence of a layer of antifungal treatment;

- the product is used to protect against dirt, dust, insects;

- thanks to this material, it is possible to permanently drain the condensate;

- polycarbonate tape contributes to the fact that the processes of expansion and contraction of polycarbonate with sudden changes in temperature are as smooth as possible;

- the product extends the service life of the base material by several years.

It is thanks to these characteristics that polycarbonate tape is popular and in demand among users.

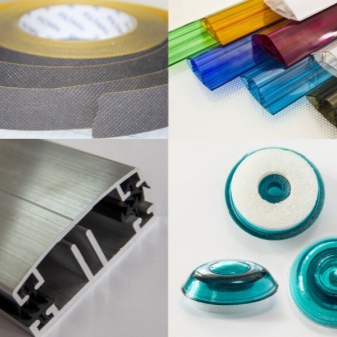

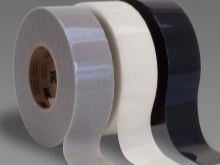

Species overview

Due to the fact that polycarbonate tape is an important (and in some cases irreplaceable) building material, several types of it can be found on the modern market. So, for example, you can purchase material options such as: protective, end, adhesive, vapor-permeable, heat-insulating (or thermal tape), sealed, self-adhesive tape, as well as material for gluing, protecting and repairing cellular polycarbonate. For the convenience of users, manufacturers of polycarbonate tape have divided the material into several categories.

Sealing

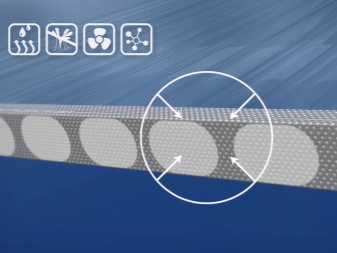

The sealing type of tape (also called "hermetic tape" or "sealant") is used to protect the seams and joints of polycarbonate sheets from negative influences from the outside (in other words, for sealing). Due to the fact that polycarbonate is a material that consists of cells (or honeycombs), there is a need to prevent moisture, dust and any other unwanted debris from entering them.

Polycarbonate sealed tape consists of several layers. The external one acts as a direct sealant and consists of plastic, durable and reliable in its characteristics. On the other hand, there is a special adhesive on the inside, which is characterized by a long service life.

In addition, the distinctive characteristics of this type of tape include the fact that it has a high level of flexibility. Accordingly, its use is possible on any surfaces (regardless of their shape).

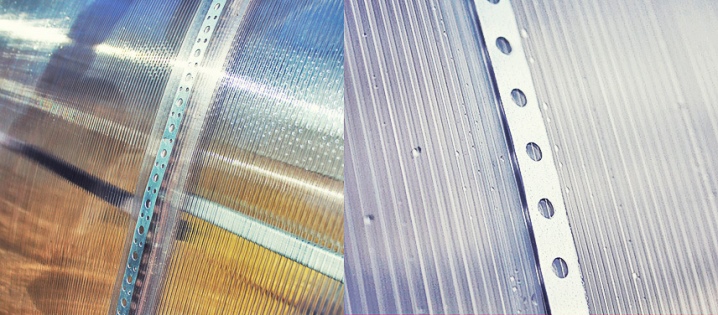

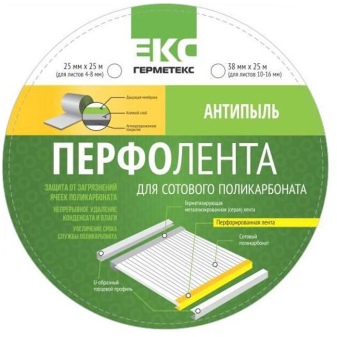

Perforated

Perforated tape (or punched tape) is used in situations where a variety of suspended structures (for example, an air duct) are being erected. In addition, the use of this material is relevant during the arrangement of the so-called warm floor (in this case, the product is used to fasten the cable). Another option for using punched tape is the installation of rafter systems.

Such widespread use of perforated tape is due to the presence of a large number of positive characteristics of the material. Among them, first of all, one can distinguish:

- possibility of use even in unfavorable conditions (for example, with high air humidity, variable temperature, UV radiation);

- high level of strength and reliability;

- resistance to corrosion processes;

- easy and straightforward installation process;

- affordable price;

- long term of use.

The distinctive characteristics of punched tape can also be attributed to the fact that it is equipped with a special microfilter, therefore this material is often called anti-dust. Perforated scotch tape for the ends creates an optimal microclimate and eliminates unwanted friction processes.

If we talk about the material of manufacture, then it should be noted that the raw material for the punched tape is thin low-carbon galvanized steel. And also the composition includes aluminum. Externally, the tape has a silvery tint. In addition, this material has a self-adhesive base, which is characterized by high adhesion.

Thus, we can conclude that The 2 main types of polycarbonate tape differ in their appearance, purpose and properties. When choosing, it is imperative to pay close attention to this.

Dimensions and materials

Since polycarbonate tape is widely used, manufacturers produce material in several sizes:

- 25 mm - suitable for polycarbonate from 4 to 8 mm;

- 38 mm - for material from 10 to 16 mm;

- 45 mm - suitable for polycarbonate from 16 to 25 mm.

In addition, it should be borne in mind that polycarbonate tape may differ not only in its size, but also in the material of manufacture. So, modern manufacturers use several materials in the process of making tape, namely: highly elastic polymers and adhesive acrylic glue.

How to choose?

The choice of tape for polycarbonate should be approached as carefully and responsibly as possible. At the same time, experts advise taking into account several key parameters.

- Appointment. Initially, you need to figure out what purpose you will use the tape for. What type and size of material you choose depends on this decision. Accordingly, you must make this choice even before purchasing the material.

- Manufacturer. Preference should be given only to those products that are produced by manufacturers who enjoy the confidence of consumers. This is due to the fact that only such a tape will meet all the necessary requirements, and its production will comply with generally accepted (state and international) standards.

- Place of purchase. You should buy polycarbonate tape only in specialized hardware stores, where you can get expert advice from sellers and managers.

- Reviews. Before purchasing a feed, you need to carefully study user reviews and comments. In this case, you will be sure that the quality declared by the manufacturer will fully correspond to the real state of affairs. Given these characteristics, you can purchase a tape that will 100% meet your needs and perform well its functions.

How to use?

Of particular importance is not only the choice of a suitable type of polycarbonate tape (in terms of variety and size), but also the correct use of the material. Experienced builders recommend adhering to simple instructions in the process of using the material and compulsorily following the recommendations of specialists.

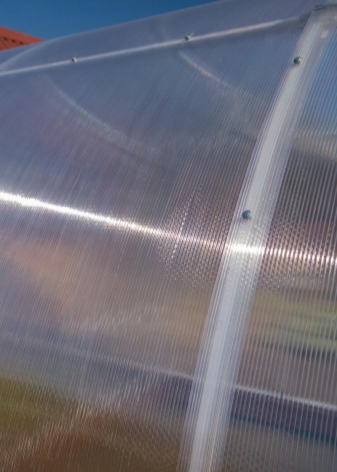

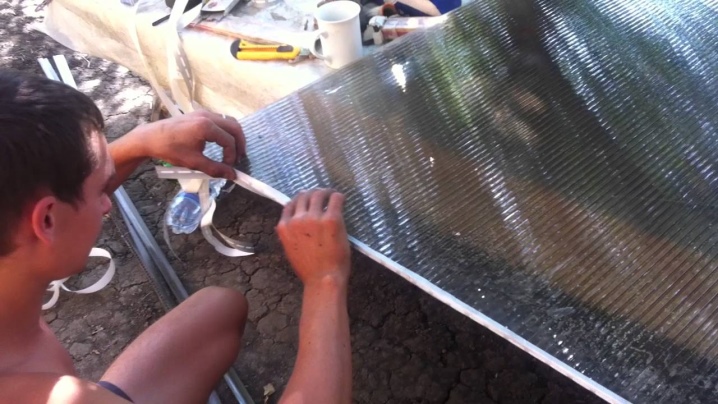

First of all, it is necessary to prepare polycarbonate panels.They need to be cut to size (which is relevant in a particular case), then holes are made specifically for thermal washers. After that, it is necessary to start the process of blowing out the honeycomb. Only after the completion of these processes, you can proceed to the direct gluing of the tape.

Before gluing the tape, you need to carefully process the polycarbonate. It is important to remove any existing bumps, scratches and any other defects. This will allow the tape to be glued to the surface as accurately as possible, respectively, the tape will effectively perform its tasks. In those areas where the tape will be glued in the future, you need to remove the protective film from the polycarbonate.

At this stage, you can start directly applying the tape to the ends of the polycarbonate. Wherein it is important to pay attention to the fact that the edges of the tape are neatly and evenly distributed over the polycarbonate. To ensure this effect, it is necessary to stretch it during the application of the tape (however, this must be done in such a way as not to break the material). In addition, in the process of gluing the tape, attention must be paid to ensure that no folds appear on the surface of the material.

After you have attached the tape, press down the edges using a soft felt cloth. In this case, excessive pressure should not be exerted on the material, so as not to spoil or destroy it. After completing the above steps, the end profiles should be installed over the material. At the same time, remember to keep a small gap (2-3mm). Such a gap is a drainage one, since it is used to drain condensate.

Helpful advice. Do not look for a replacement for polycarbonate tape and use materials such as tape or duct tape instead. The thing is that the replacement will not fully fulfill the functions assigned to it. Conversely, the use of tape or electrical tape can negatively affect the overall strength of the structure.

Thus, we can conclude that tape for polycarbonate, despite the fact that it is an auxiliary building element, plays a very important role. Its use will significantly increase the strength and reliability of the structure. In this case, it is worthwhile to carefully approach the choice of material and take into account all its characteristics, so as not to regret the purchase made in the future.

For information on how to seal the ends of polycarbonate with different types of tapes, see the next video.

The comment was sent successfully.