How and how to cut polycarbonate?

Every day, polymer plastic canvases are gaining more and more popularity among the people. Due to its low price and excellent technical parameters, polycarbonate occupies a leading position in the field of sales of building materials. A significant role is played by the fact that any person can work with polymer plastic canvases, even without experience in the field of construction. However, due to the fact that polycarbonate has recently appeared on the market, the technology of its cutting is not known to everyone.

Tool selection

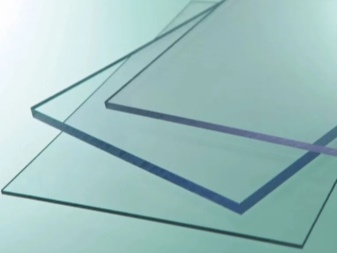

Polycarbonate is a synthetic polymer material that has gained recognition in the construction industry since its inception. Its distinctive features are transparency, flexibility, low weight and a high level of strength. The last presented characteristics distinguish it favorably from natural glass, which was the reason for the massive use of this material as a practical analogue.

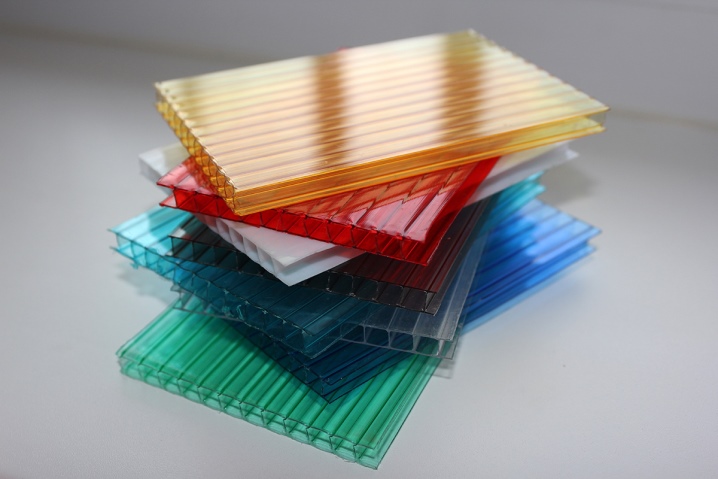

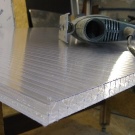

Today in the construction market, polymer plastic canvases are presented in several types.

- Monolithic. This type is a solid polycarbonate sheet. It is convenient to cut, bend and mount it. The only drawback is that after cutting, the edges of the material need to be smoothed and deburred.

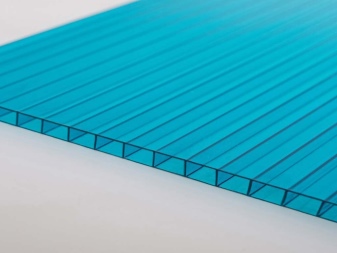

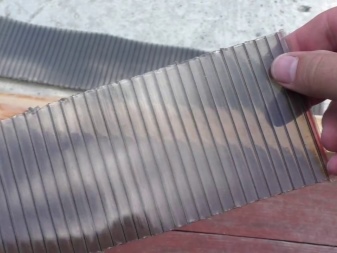

- Cellular. This type of material has stiffening ribs between several layers of sheets, which is why hollow spaces appear in the distances between the ribs, or, as they are also called, "honeycombs". That is why this type of polycarbonate is called "cellular". The number of air chambers present in the cellular webs of polymer plastic is at least 5 compartments. By the way, cellular polycarbonate is more convenient to cut across the honeycomb.

The choice of a suitable tool for cutting polycarbonate depends entirely on the type of board, its thickness and the complexity of the cut line.

Of course, making a cut in a straight line is much more convenient than creating a curved line, but sometimes you need to make a notch or shape a curved slot on the sheet. For each individual case, the most appropriate option for a sharp instrument should be considered.

A small set of cutting objects that can be used at home is always present in the essential construction suitcases. but if there is a need to cut out miniature decorative elements, it will not be possible to do without the services of a laser or milling machine.

Without using high-precision cutting devices, the sawn edges of the monolithic sheet will have to be sanded. The extreme parts of cellular polycarbonate are not sanded; it is enough to close them with an end profile. Experts, in turn, recommend the use of edge profiles. Such models have protection that prevents debris and insects from entering the hollow space.

Further, it is proposed to familiarize yourself with a list of tools that are ideal for cutting a web of polymer plastic, especially since most of them can be found in garden tools:

- knife - an ideal tool for cutting polymeric plastic sheets with a thickness of 4-6 mm;

- jigsaw - best suited for home cutting of small curly lines;

- Bulgarian - a tool suitable for cutting thick sheets of 8-10 mm;

- a circular saw - the best way to cut curly lines;

- hacksaw for metal - a tool that is worth thinking about as a last resort.

By the way, for cutting a sheet of polymer plastic with a thickness of 2-3 mm, metal scissors can be used. It is strictly forbidden to use a hacksaw on wood. It does not cut, but tears apart the plastic, leaving sharp stumps at the ends. Discs for steel processing are also contraindicated. During operation, the disc heats up and melts the plastic base of the polycarbonate.

Before taking a tool for cutting, you need to carefully study its features and understand the nuances of work.

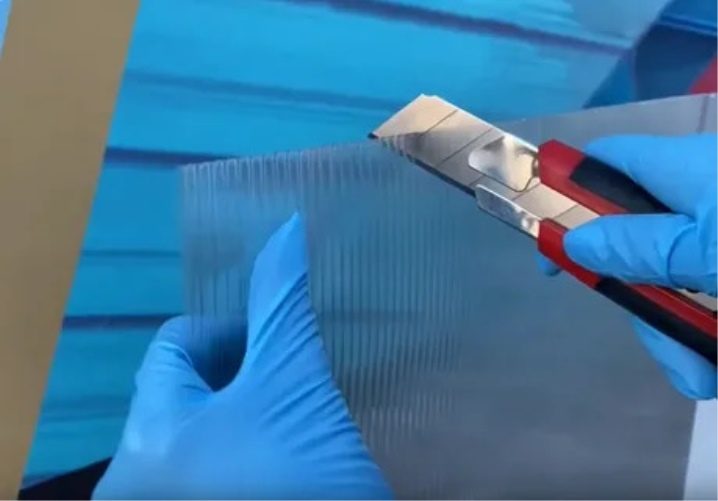

Stationery knives

This tool is necessarily present on the farm. It is used for sawing and cutting any materials, things and objects. It is also considered an ideal tool for cutting thin polycarbonate in a straight line. Basically, you can use a clerical knife to cut wriggling elements, but it will take a very long time.

A knife for cutting polycarbonate should be as sharp as possible, otherwise the cut will be of poor quality. Accordingly, the ends of the cut material will have to be sanded.

It is not recommended to use a knife for cutting polycarbonate with a thickness over 6 mm. The same goes for monolithic sheets.

Grinders

A good tool for cutting straight lines. It can even help you cut with a wide radius of curvature. It is impossible to cut small circles with a grinder. First, the disc gets stuck in the cut of the web to be divided. Secondly, the cut is obtained with ragged ends.

To make the cut ends of the polycarbonate smooth and have a beautiful frame, the tool should be set to low speed.

The disc itself must be designed to work on aluminum or concrete. This is the only way to make a high-quality and even cut of polycarbonate. Planks must be placed under the sheet to be sawn to create a gap that allows the disc to move freely along the working surface.

Electric jigsaws

When creating a straight cut, you can use a variety of sharp tip or blade options. It is much more difficult to separate monolithic or cellular polycarbonate according to figured patterns.

For such work, it is best to use a jigsaw. Its file easily repeats the required bends, does not get stuck between the blades. However, not just any file is suitable. Ideally, you should use a small model with fine teeth on the same plane. Otherwise, the edges of the cut polycarbonate will be uneven.

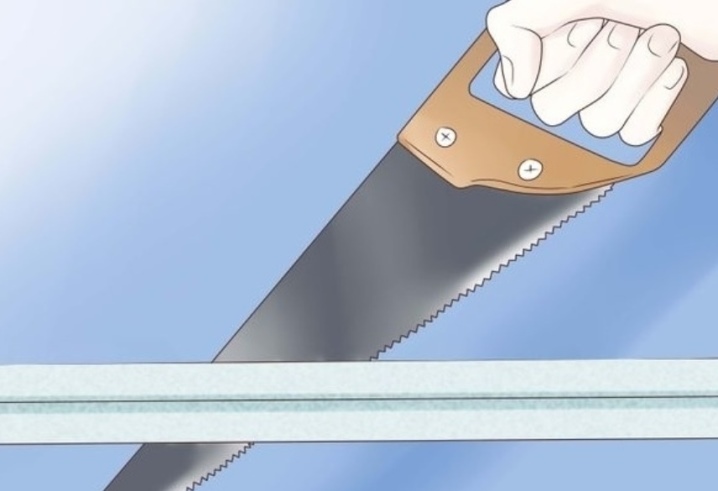

Hacksaws

This construction tool for working with polycarbonate should be considered as a last resort. Firstly, it is very inconvenient to work with him. Secondly, it will require a lot of labor.

Basically, you can make neat, straight, straight cuts with a hacksaw, but only if the sheet is firmly fixed. The movements of the cutter themselves should be smooth. Do not jerk and rush, one jerk can lead to edge cracking.

Another challenge with a hacksaw is the need to hold the tool at a 30 degree angle while cutting.

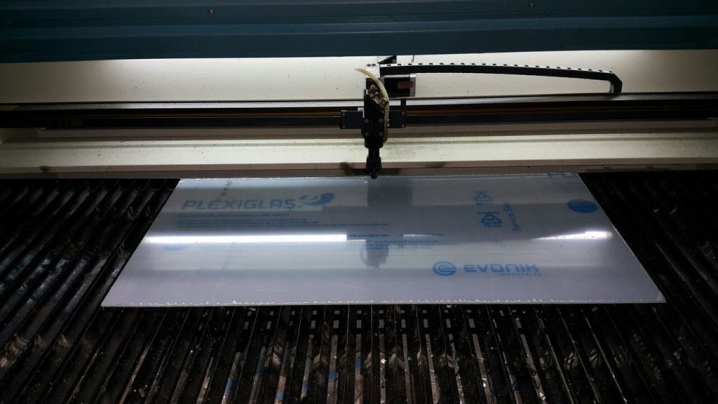

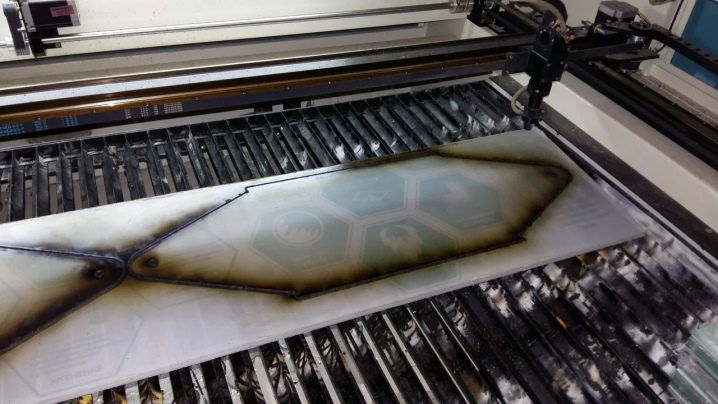

Laser

Laser cutting is intended for the manufacture of decorative elements from polycarbonate and other materials. Not everyone can install laser equipment at home. Moreover, to work with the device, you must have sufficient professionalism.

An important advantage of laser cutting is the minimum cutting error and perfect cut edges free from burrs.

How to cut correctly?

Having made the markings, you can start cutting the polycarbonate. It is not difficult to cut a cast slab at home. It is much more serious to take the processing of cellular polycarbonate. Today, there are several ways to cut a web of polymer plastic, involving the use of different tools. Each option has certain advantages and disadvantages. That is why, before starting work, you need to get acquainted with each specific tool and choose the most suitable method.

Knife cutting

Many people believe that a clerical knife is the perfect tool for cutting polycarbonate at home. The main thing is that the blade is as sharp as possible. It is recommended to replace it before work.

Of course, cutting polycarbonate with a construction knife is not an easy job. It is much easier to use a jigsaw or grinder. Another inconvenience is that the knife can be used on small pieces of material.

Further, it is proposed to familiarize yourself with the step-by-step instructions for carrying out cutting work with a knife blade.

- It is necessary to prepare the site, make markings on the sheet.

- Make a test cut on a part of the polycarbonate sheet. Thus, the sharpness of the knife is checked.

- A ruler or level is applied to the cutting line.

- A blade is installed on the front side. A knife is inserted into the end part, creating a notch. Next, the blade is guided along the cut line. It is strictly forbidden to rush, otherwise the knife will go beyond the markings.

In practice, it has been found that a construction knife is ideal for cutting. The cutter from the stationery store is also good, but dulls very quickly.

Jigsaw cutting

The best analogue of a construction knife and grinder.

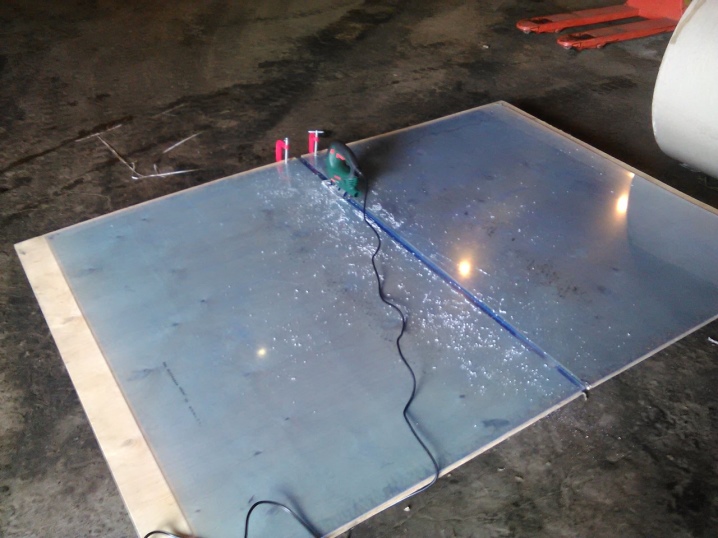

- The process of cutting polycarbonate with a jigsaw begins with the standard preparation of the workplace. When installing the file into the base of the jigsaw, check that it is securely fastened.

- The device is connected to the network, then it is brought from the end side of the polycarbonate sheet, according to the markings made. If it is necessary to create wavy lines, it is best to practice in advance on other materials.

- At the end of the work, you must turn off the jigsaw and get rid of the plastic shavings. If excess elements remain on the edge of the polycarbonate, they must be cut off with a clerical knife.

Grinder cutting

The grinder is a convenient tool that allows you to cut a large sheet of polycarbonate to the ends in a short period of time. For work, you need to take a disc for metal. The appliance itself must operate at low speeds, thereby minimizing the possibility of melting the plastic base of the material.

Further, it is proposed to familiarize yourself with the cutting technique with the help of a grinder.

- It is necessary to prepare the work surface. Place the scaffold.

- Then the grinder turns on, the necessary speed is gained. Then the metal disc is brought to the marking. It is important to move the device carefully, constantly monitor the position of the disc so that it runs clearly in a straight line.

- At the end of cutting, you must unplug the grinder from the outlet. If cellular material has been processed, shake out the plastic shavings from the voids.

Hacksaw cutting

You can use a metal hacksaw to cut polycarbonate. This tool helps to cut material into parts of different shapes. The process of work itself is in many ways similar to cutting with a construction knife, however, some nuances must be taken into account:

- the hacksaw should be at an angle of 30 degrees at all times;

- to create a more comfortable working environment, you should use a workbench that allows you to fix the sheet in a vice.

Laser cutting

This cutting method is mainly used in an industrial environment. Only a highly qualified specialist who knows the technology of the process can work with this tool. but Today you can buy laser equipment for home use.

Thanks to the combination of modern technologies and software control, the cutting accuracy has a maximum error of 0.5 mm.

Therefore, the products are perfect in size. But unfortunately, not everyone can afford to purchase laser equipment. It is very expensive, and for a single use it makes no sense to spend such a large amount of money. For this reason, users who need to make curly cutouts give polycarbonate sheets and the design of the pattern to specialized workshops, where professionals in their field customize the equipment and turn the customer's idea into reality.

The most important feature of laser cutting, to which connoisseurs of exquisite beauty turn to, lies in the smooth lines and accurate transfer of the conceived image or ornament.

Helpful hints

When choosing a tool, you should take into account the size, thickness of the sheet and the complexity of the cut line. Thin monolithic sheets are much more convenient to separate with a construction knife. It is very convenient to prepare straight cuts with a grinder or circular. For the design of rounded shapes, it is preferable to use a jigsaw.

If the surface of the polycarbonate has a mirror or laminated finish, the material must be laid with the decorative side up before cutting.

If you want to create a figured hole, in that place you need to drill through the polycarbonate with a drill for metal. It should not go beyond the contour line of the shape being created. A small partition is made with the same drill.

A jigsaw file or a sharp construction knife is inserted into the prepared hole. After that, a neat cutting of the figure begins. This work takes a lot of time and effort. And in order not to waste their own energy and nerves, it is best to use laser cutting.

In the process of cutting polycarbonate from a monolithic or cellular sample, it is important to adhere to some recommendations, thanks to which the result will exceed all possible expectations.

- Before you start cutting, you need to prepare your workspace. Namely, remove debris, specks and even small specks of dust. It is recommended to put chipboard or plywood on a clean surface and lay polycarbonate on top.

- When using an electric tool, it is important to remember your own safety.

- Using a grinder or jigsaw, it is necessary to install special supports under the polycarbonate sheets along the edges or along the cut line.

- You can't try to make a straight line by eye. Only thanks to the marking will it be possible to cut the material evenly.

- The most important thing is to choose the most convenient tool for cutting. It is important to adhere to the technology of working with it and the sequence of actions.

In the next video, you will learn how to properly cut polycarbonate for a greenhouse.

The comment was sent successfully.