Which side should I put polycarbonate on?

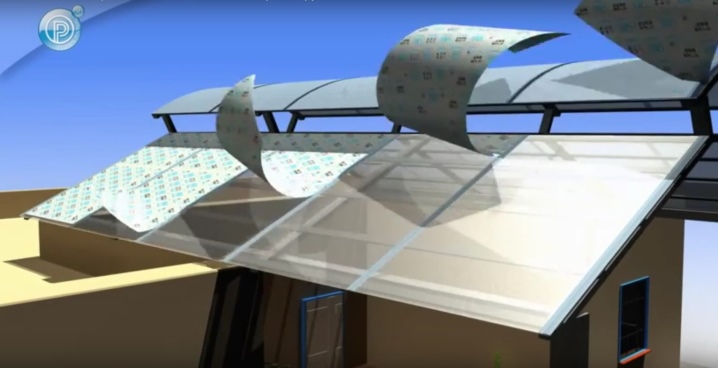

Plastic sheet is the name of the material popularly known as polycarbonate. The highest quality and most popular is the cellular type of polycarbonate. Due to its lightness, high strength and the ability to transmit light rays well, it is actively used in home private construction. This is the best option for the manufacture of greenhouses, canopies and awnings. If you know the basic rules of installation and how to properly mount polycarbonate, you can easily build a reliable and durable structure with your own hands.

Why is it important to fix polycarbonate correctly?

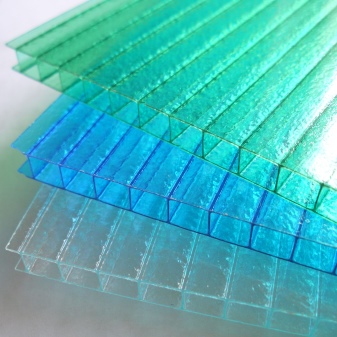

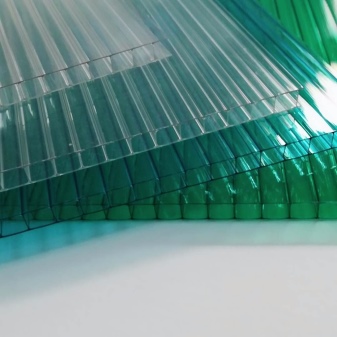

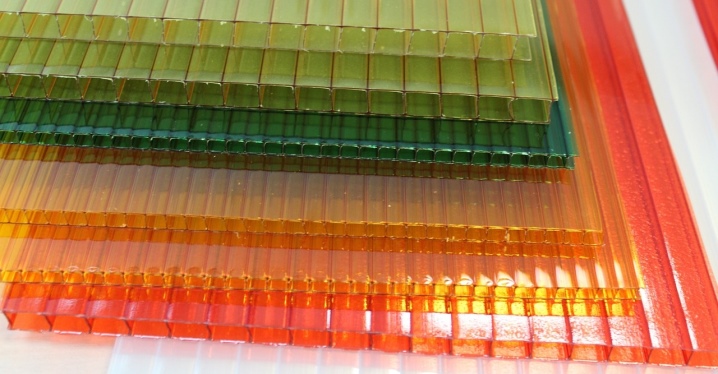

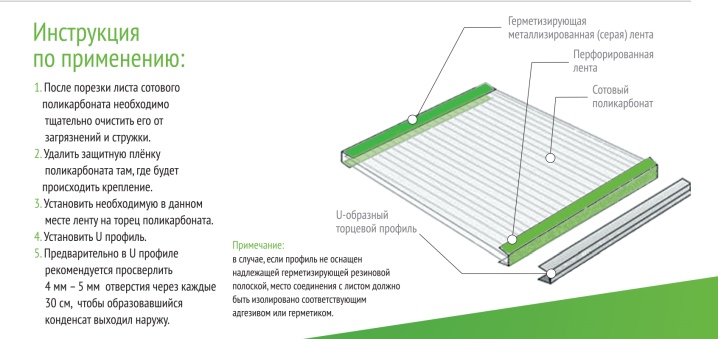

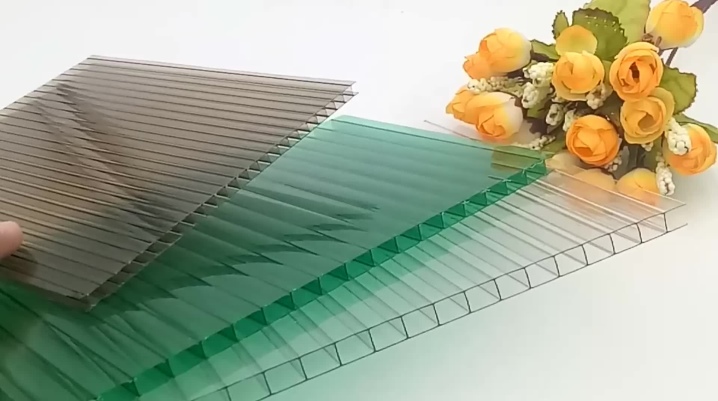

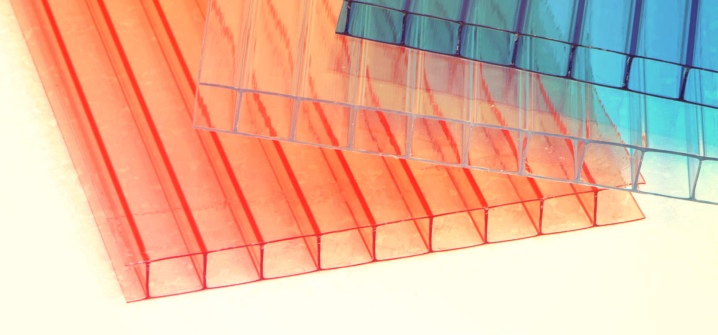

The honeycomb product was named for the visual similarity of the structure in the context of the honeycomb. Cellular polycarbonate in the slab consists of several polymer layers connected by longitudinal reinforcing bridges. The minimum number of sheets is two, the maximum is four.

With this structure, the material provides good thermal insulation.

The luminous flux passes through polycarbonate by 90% or more, besides, the strength of the synthetic material is a hundred times higher than that of glass. Polycarbonate bends well, remaining resistant to mechanical damage, for which it is often chosen for the construction of arched canopies. When struck, cracks do not go on it, so even a hail attack is not afraid of it.

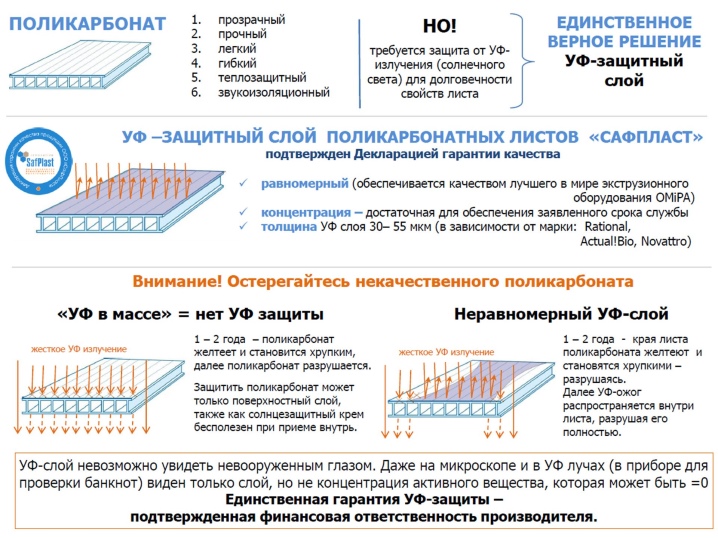

Although polycarbonate is one of the strongest and most reliable polymers, it can degrade in sunlight. It so happens that polymer plastic used as a cladding for a greenhouse, greenhouse, outdoor gazebo, veranda and similar open-type buildings quickly wears out.

It takes only a couple of years from the moment of installation, and the cladding completely loses its original physical characteristics and declared qualities.

This happens in two cases: when the polycarbonate sheet is laid incorrectly or does not have special treatment from ultraviolet radiation.

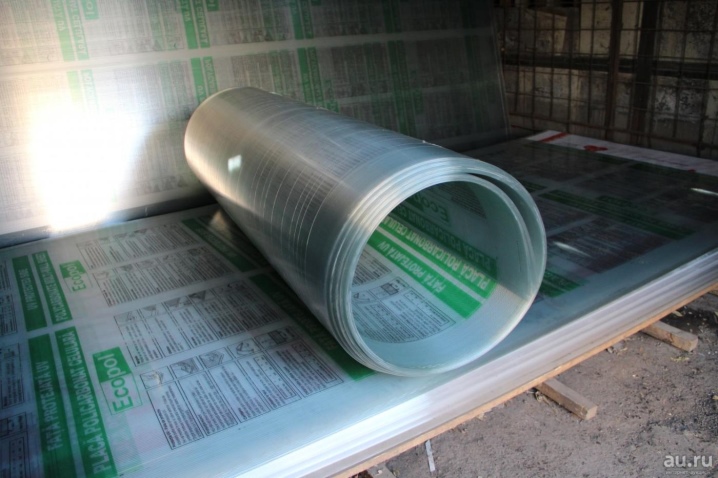

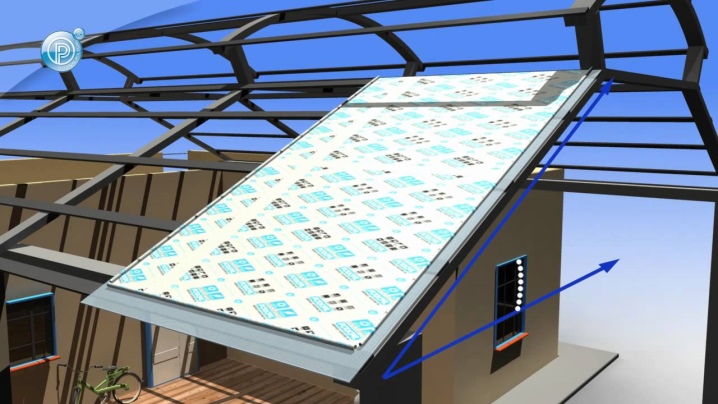

The presence of a protective layer against ultraviolet radiation is the most important quality of polycarbonate. If you attach the sheet with the treated layer inward, you can immediately reduce its service life by a whole decade. Determining the right side with resistance to the damaging effects of the sun is not difficult: it is covered with a packaging film with a list of product data and its parameters. There will be no markings on the back of the film.

There are several ways to apply UV protection.

- Spraying. A thin layer of a solution is applied to polymer plastic, which looks similar to industrial paint. The considered method has significant drawbacks. During transportation and installation of the polycarbonate sheet, the protective layer is damaged, which makes the polymer unsuitable for efficient operation. Spraying as UV protection demonstrates instability to various atmospheric conditions and does not tolerate mechanical stress from the outside.

- Extrusion protection method. At one of the stages of production, a special layer is applied to the canvas to prevent the destruction of the polymer. It penetrates the surface of the polycarbonate material. The canvas receives resistance to damage of various kinds, including mechanical stress. The difference with the previous method also lies in the service life of polycarbonate - at least 20 years.

The polycarbonate sheet is delivered to the customer in a packing film (on both sides). It must be removed upon completion of installation, otherwise, under the rays of the sun, the packaging will firmly adhere to the sheet and cause it to turn yellow. It so happens that the master removes the film, forgetting to mark the UV-protected surface, which should be directed outward. Determining the right side is easy in this case too. You need to take a polycarbonate sheet by the end and look through it at the sun. Purple reflections will appear on the UV coated side. In principle, such a test may or may not be carried out, replacing it with a call to the supplier.

A competent specialist will help you figure out which side should be laid out and which side should "look" inward. Sellers probably know the technical characteristics of their product. Cellular polycarbonate sheets have a film that prevents the destructive effects of ultraviolet radiation. Moreover, the outside of the canvas has a coating that transmits a certain part of the light spectrum. The maximum luminous flux gets through the coating with polarized mica particles, and harmful infrared radiation is reflected. In rooms glazed with polycarbonate, under intense light, the air heats up slightly, which improves the microclimate in hot weather. Such polycarbonate sheets are distinguished by a pearlescent, pearl or golden hue.

Another type of polycarbonate is more suitable for greenhouse applications. It lets in enough light for optimal vegetation growth while keeping the damaging radiation outside. The important thing here is which side to mount the polycarbonate on the greenhouse. When a leaf does not lie down correctly, climatic conditions are formed in the greenhouse, which have a detrimental effect on vegetation.

Deprived of a barrier to UV radiation, polycarbonate will gradually lose its strength and will soon deteriorate.

Another type of cellular polycarbonate is a material with high reflective qualities. The aluminum-sprayed coating resists greenhouse effects and provides a cool shade. Plates are produced in several color variations: silver, green and blue.

How to determine the front side?

Before laying the canvas, you have to figure out which side will be the outer one. You need to consider a polycarbonate sheet. Packaging films are usually labeled and have precise instructions in multiple languages. It also describes the basic recommendations for installation. By the presence of information labels, the "outdoor" of the material is calculated. In the process of mounting, the sheet should be turned upwards in the direction of the sun. The information on the protective film helps consumers not to make mistakes in the manufacture of greenhouse structures and sheds using a cellular variety of polycarbonate.

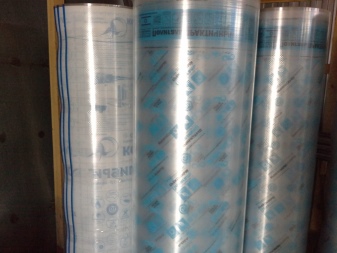

In order to correctly carry out the installation and understand which side to install the polycarbonate sheet, there is often a protective film of different colors on its surface. On the underside, it is always white or colorless. Above, the film is either blue or with a pattern, with markings. In any case, the sides are obviously different from each other. There is always double-sided protection on high-quality polymer plastic. The colored side indicates UV protection.

It is worth considering the marking carefully, important points concerning polycarbonate are applied to the protective film from the "face":

- designation and name of the material;

- basic technical characteristics;

- manufacturer information;

- installation rules.

Based on the foregoing, it is clear that the definition of the outer side of the polymer plastic sheet is an important step when sheathing the frame. If for some reason there is no protective film, there is still a reliable way to determine the front side to which the sheet is to be fixed - a special laser notch. Marks are applied along the edges in the upper part of the canvas at a distance of 70-80 cm. The purpose of such labeling is to help the consumer in resolving the following issues:

- how to choose the front side of the covering material when there is no protective film;

- how to install the flooring according to all the rules;

- how to identify the material in the course of use.

On the modern market of building materials, honeycomb polymer plastic with double-sided UV treatment is presented. On this product, the manufacturer does not provide for marking on the outer film. Thanks to this quality of cellular polycarbonate, you can not waste time looking for the front edge, but lay the panel with either side out.

How to fix it correctly?

After purchasing polycarbonate, the buyer is often puzzled by the question of whether it is necessary to clean the plastic sheet from the film. The correct answer is the recommendation to remove the film immediately after installation in order to avoid problems in the future. This is a shipping film that covers the sheets during transport and storage, so it must be removed when no further shipment is planned.

Some summer residents take the transport film as a protective layer from UV. Leaving it on the panels, they expose the material to the destructive influence of the sun. It is worth knowing that the UV layer is invisible - it will not be possible to peel it off on an unspecified basis. Therefore, there is no need to be afraid to accidentally remove the excess due to inexperience. If the film on the outside of the sheet remains unremoved, it will firmly stick to the top of the material with the dark areas of the inscriptions, and after that it will be simply unrealistic to remove it. Moreover, the film on the outside of the canvas threatens the safety of the layer that protects against ultraviolet radiation. In winter, the film that has not been removed will trap the snow.

This reduces the strength of the sheets and shortens their service life.

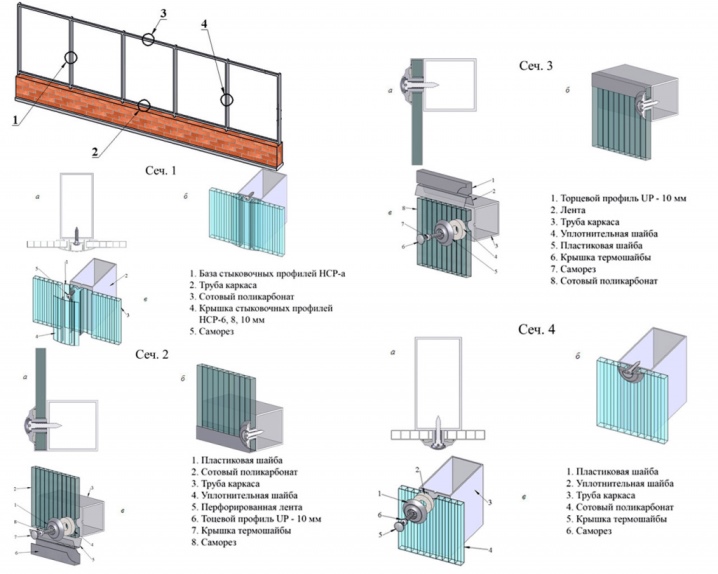

When installing, it is also important to take into account the ability of polycarbonate to respond to temperature changes. In hot weather and cold, standard polycarbonate exhibits deviations from the original width by 1 cm or more. If at the same time the sheet is tightly fixed on the frame, the appearance of cracks with the subsequent destruction of the material is inevitable. To prevent this from happening, the holes for the screws should be 3-4 mm larger in diameter than the screws themselves. This will prevent possible deterioration of the material when it changes during thermal expansion. It is important not to over-tighten the bolts, otherwise the sheet may be deformed.

Also, you can not bend the material more than the prescribed norm. Each type of polycarbonate is characterized by a certain flexibility and specific indicators of the minimum bending radius. If the sheet is bent more than permissible, folding during transportation or laying out on arched structures, the polycarbonate will burst during the first thermal expansion, and the tightness will be broken. Water will ooze through the break when it rains. This part of the structure will be unsuitable for further operation, and it will have to be replaced. The maximum radius is determined by the thickness of the polycarbonate - the thinner, the more it is allowed to bend the sheet. For reliability, you need to check with the seller about such qualities.

With proper installation and adherence to the installation order, the constructed structure made of cellular polycarbonate will serve for many years without problems.

How to properly lay polycarbonate, see the next video.

The comment was sent successfully.