Wooden floors: device and installation

With all the popularity of building stone and synthetic materials, in some cases it is simply impossible to do without wood. It is also used in the construction of floors. But in order to exclude mistakes, it is necessary to thoroughly understand the structure of the wooden floor and the method of its construction.

Peculiarities

Speaking about the features of wooden floors, one must immediately point out the specifics of the design of the basement or attic elements of the building. Both are the most common options; it is much less common to create overlaps in other places. Basically, the composition of the structural block includes beams from a bar or log. A prerequisite is the closure on both sides with sheet materials or a high-quality wooden board. When arranging a wooden floor, be sure to think over how:

- its bearing capacity;

- thermal characteristics;

- acoustic properties.

In some cases, you have to:

- use insulation (usually inside the structure);

- apply a vapor barrier;

- carefully select the placement of the beams, taking into account the minimum deflection.

Interfloor and attic floors are constructed from fibreboard and chipboard, from oriented board and plywood. Putting it all have to over the beams.

Quite often, the sheathing is attached directly on the base of the floor. Then the structure acts simultaneously as a ceiling for the lower room and a subfloor from above. In most cases, the flooring is nailed down; if they are not used, the bearing characteristics will be worse.

The gap from one beam to another is sometimes reduced if it is related to the characteristics of the deck.

Base / plinth overlaps are created from:

- unedged boards;

- slab;

- log rolls.

Advantages and disadvantages

It is useful to compare wooden and reinforced concrete floors, since it is these two options that turn out to be the main rivals. Steel beams are obviously used less frequently and mainly in industrial and special construction. Wood products are distinguished by a relatively modest weight. For 1 sq. m. of wood accounts for 350-400 kg.

Reinforced concrete, even "lightweight", cannot weigh less than 700 kg per 1 sq. m.

Reducing the weight of the building structure not only simplifies the work of installers and makes it easier to transport the load. At the same time, the cost of work is also reduced. And the opportunity to get by with a “simpler” foundation is very attractive. If the spans are relatively small, and the placement step is frequent, then wooden elements can be laid out without special lifting equipment. Manages to get by with the direct efforts of the participants in the construction themselves.

It is also important to emphasize the high speed of work. Wooden floor slabs are completed in just a few shifts. To do the job as quickly when using reinforced concrete will certainly not work. But it is important to understand that there are cases when slabs are better than wood. Even the best wood deforms too easily.

It is easy to see how the floor vibrates when walked on. True, this does not confuse all people. But due to too slight a shift, cracks may appear in the layers of plaster, sometimes the seams that separate the sheets of finishing structures open.

In most cases, wooden floors are used as a substrate for wooden floors.After a few years, unpleasant extraneous sounds may occur. The stone floor is devoid of these disadvantages. In addition, it dampens sounds much more efficiently. It is possible to combat the penetration of extraneous noise through the wood by means of additional backfill. But at the same time, such advantages as ease and speed of construction are lost. In addition, making the overlap heavier does not always help to fully solve the problem.

Wooden structures can burn, fire spreads through them very quickly. Both disadvantages can be mitigated, of course, by special impregnations. But then it is already impossible to speak completely about the naturalness of the overlap, about its ecological purity. The impregnations will have to be repeated from time to time, as they gradually lose their properties.

Special processing significantly increases the cost of construction and major repairs.

The tree can suffer from mold and other fungi, from woodworms. It is very sensitive to moisture penetration, especially when mixed with aggressive substances. Warping of wood, the appearance of cracks is often noted. The service life of even a perfect wooden floor with the most careful maintenance does not exceed 50 years. Finally, reinforced concrete clearly wins in places where there is a great danger of a destructive earthquake.

Technical requirements

When constructing a wooden floor you can focus on the norms from SNiP II-25-80. According to this standard, it is required to provide protection against water ingress and against harmful biological agents. In places where exposure to an aggressive environment is likely, care must be taken to protect against corrosion. Calculations for the bearing capacity and the non-critical level of deformation are carried out in advance. It is impossible to use glued timber floors if the air temperature even for a short time exceeds 35 degrees.

Coniferous wood is preferable for work. In some cases, hardwoods are used. According to GOST 4981-87, beams must be made of softwood. For cranial bars, the use of hardwood blanks that meet the established requirements is allowed.

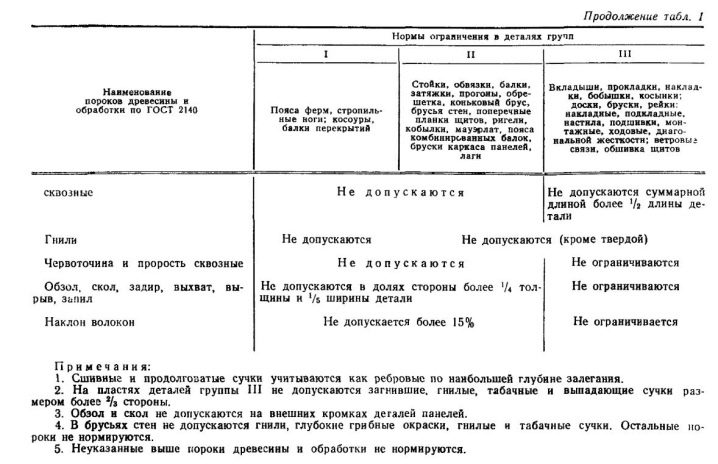

You can not use a tree worse than the second grade. You can also not use parts that in which end-to-end cracks are longer than 0.1 m. The assessment of the breed and variety group is carried out visually. To accurately determine the vices, they are guided to the instructions of GOST 2140. Interfloor ceilings in a private house can be used without much difficulty, but additional nuances must be taken into account. So, in the attic rooms, you will have to additionally strengthen the beams.

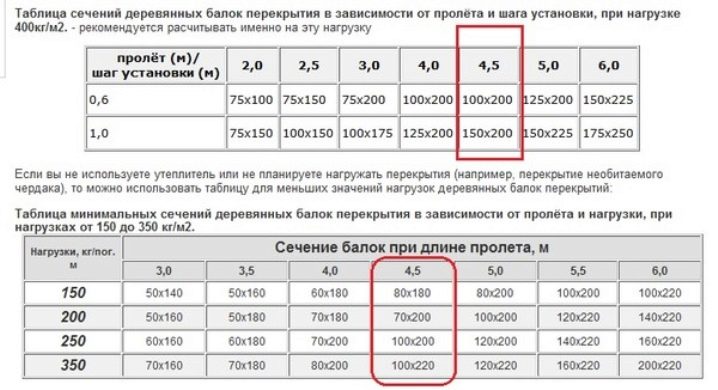

The maximum span length is 8 m. The smallest section of the beam is 0.05x0.15 m, and the largest is 0.14x2.4 m. The largest parts are rarely used in private houses, because the load-bearing load there does not justify such a thickness of the material. It is allowed to use beams made of solid sanded logs.

Experts strongly advise to thoroughly dry all workpieces before laying in the designated place. The distance from one beam to another is 0.6-1 m. This indicator is influenced by:

- the number of floors in the building;

- load value;

- total area of the structure.

The length of the beams should be such that they are firmly supported by the walls in specially designated places. The arrangement of the floor under the cold attic has its own nuances. Since it combines a load-bearing and heat-insulating function, it will be necessary to equip a multi-layer block. Parts of the "pie" and their sequence are selected as carefully as possible. Non-residential premises can be equipped without a finished floor.

As for the beams, they are either installed on the protrusions of the walls, or walled up in these protruding parts. You definitely cannot use a tree if the building is longer than 10 m. Even more, spans longer than 6 m can be built only from special blanks, which are significantly more expensive than simple lumber. In addition to insulation, you will have to take care of waterproofing and vapor protection. The wooden floors of the second floor can even be used in a brick or concrete building.

The limiting (critical) level of load of interfloor and basement structures is at least 210 kg per 1 sq. m. If the attic is located at the top, then this figure is at least 105 kg. However, in the case of a residential attic or when storing a large number of heavy objects, they are guided by the highest indicator.

The highest level of deflection per 1 lm is 0.004 m. If it is larger, then it becomes dangerous to use such an overlap.

When laying ceramic tiles and other heavy floor coverings own deflection of a wooden floor is limited to 0.0025 m per 1 rm. But in the case of a non-residential little-used attic, you can increase the permissible level to 0.005 m. But it is still better not to skimp on the thoroughness of the calculations and make a better structure.

Then in the future, if you need to remake a simple attic into an attic, you will not have to remodel the floor. You also need to think about soundproofing. No more than 50 dB of extraneous sounds should pass into the living space. Experts recommend using soundproof materials, which are also insulation. Then it will be possible to simplify the design and somewhat lighten the "pie".

When calculating the sound insulation of a two-story building, remember that noises can also pass through pipes. If they are, it is better to turn to professionals, rather than risk a loss of comfort. Regardless of the length of the wooden structures and the floor on which the floor is created, it must be treated with fire retardants and fungi. Do not use thermal insulation that does not allow steam to pass through. Otherwise, rapid destruction of load-bearing structures is inevitable.

A wooden floor on top of a plinth or foundation grillage is erected only with the use of a cranial bar. There is no other way to insulate the floor well enough. If sawdust, shavings are taken for insulation, then they are also impregnated antiseptics and substances that suppress combustion. To avoid dampness from contact with the ground, an impervious mat is required. In damp rooms, it is also placed on top.

When constructing floors in an apartment building, it is imperative to use constructive fire protection means. You will also have to exclude the slightest voids that would be limited by combustible elements.

Views

There are different types of hardwood floors. They depend on the availability of basements and whether the premises are heated or not. When a residential floor is located on top, a floor slab is applied. Structures above basements or basement floors are called basement or basement floors. Since in this case the temperature and humidity are quite different, you have to use:

- steam barrier;

- heat-reflecting film;

- insulated coating (layer of increased thickness).

When the floor is placed directly on the ground, pedestal supports are used. But there is another option - first, a pillow of concrete is poured, and then lags are laid out. Beam ceilings of the usual type are used in residential floors and in the attic. In this case, do not use specialized insulating parts. There is also no need for treatment with waterproofing mixtures.

When the overlap is made over a wooden beam or log, the largest span is 15 m.But ideally, you should limit yourself to 6 m spans.If there are wooden ribs under the ceiling, the span should not exceed 5 m.On I-beams or combined (wood-metal) ribs, you can increase spans up to 12 m. Finally, when using beam-ribbed products for support, you can make spans of 15 m completely calmly.

The overlap, erected on beams or logs, is used for the longest time. It was mastered in antiquity.The main bearing parts are rectangular or square beams. They are made of solid wood, and then laid with a step of 0.6-1.5 m. But there are also more modern solutions that use beams made of glued or plywood wood. Thanks to special technology, it turns out no worse than in the classic format.

Rectangular beams have now learned to make not only solid, but also with a void inside. The release of beams resembling a circle or an oval has been debugged. And there is even a special variety of them, similar to a complex I-beam. Differences may also concern the point of intersection with the wall.

To fix the beam on the wall, devoid of special technological passages, you will have to break through special nests... They must go deep at least 0.15 m. In most cases the depth of the excavation reaches 2/3 of the material layer.

Anchors are used for direct fastening of the beams. If there is a concrete strapping, attachment to it can be done using special brackets, anchors or brackets. Mating brackets are mounted on the log wall, held in place by powerful screws.

Overlapping on wooden edges implies the use of boards with a thickness of 0.04-0.05 m. Their height ranges from 0.2 to 0.28 m. Light ribbed flooring contains a flooring. Under it, ribs are mounted every 0.3-0.6 m. Important: the ribs must only have a rectangular cross-section, not an I-section (otherwise they will be considered beams).

Payment

Regardless of the specific technological solution, careful calculations must be made. Only they allow you to determine the most rational parameters. No wonder they are in some cases set not rigidly, but in the form of a range of numbers. When determining the length, they are guided by the specific parameters of buildings. The best thing, if the length of each slab will exactly match the span. Before calculating, they find out how deep the elements need to be immersed in the wall and how to fix it.

In a brick or in blocks, a board is embedded at 0.1 m, a beam at 0.15 m. To build a floor in a wooden house, notches are made from 0.07 m. When you plan to attach beams to special fastening structures such as a yoke or bracket, the length of the beam exactly matches the size of the span to be covered. If the beams are brought out, the rafter legs are attached directly to them; the output size ranges from 0.3 to 0.5 m. Particular attention should be paid to the calculation of loads. Their total value includes:

- own overlap weight;

- the severity of the finished floor;

- a lot of furniture;

- a lot of ordinary objects and decorations;

- load from the presence and movement of people.

To eliminate errors, it is advisable to contact professionals. But if you have some knowledge, you can do the calculations yourself. For attic floors insulated with mineral wool or other lightweight material, take a load of 50 kg per 1 sq. m. To find out the operational load most accurately, you need to refer to the regulatory documents. Be sure to apply a coefficient (usually 1.3, unless otherwise indicated) in any calculations for strength and section.

When calculating the overlap, any values are rounded up only. For actively used attics and attics, the correction factor is increased to 1.5. Do the same if you plan to use heavy fillers. By default, all calculations of the values of individual beams are carried out for a rectangular section. The only exception is when a different configuration is provided initially.

The height of the rectangle must always be greater than the width. The determination of the height is influenced primarily by the thickness of the insulation layer. In frame buildings, it is advisable to take a step between the parts, which coincides with the distance between the posts. If thick soundproofing materials are used, they are also taken into account when calculating the mass. Other information can be found in the regulatory documents.

Installation technology

The timber floor between the floors is created in any case from the support and deck structures. To select logs, you need to tap them with the butt of an ax. Normally, a ringing sound is heard. The slots in which the beams will be mounted will have to be thoroughly cleaned. After that, they are covered with waterproofing material (mainly roofing material). Only then can the floor units themselves be laid.

For your information: recesses in brick walls are treated with bitumen or bituminous mastics. The same bitumen is useful for coating the end parts of the beams. In wooden houses, supports are often cut in according to the "dovetail" system. The advantage of this approach is simplicity and excellent stability.

In some cases, instead of boards, they use girder trusses. They are much more practical, if only because 100% even board is a rarity. Even in private houses, the farm covers large spans much better.

Also sometimes used beam I-beam. It is longer than the board, at the same time it is not subject to drying out and twisting. Such beams are usually manufactured in industrial plants. Above and below belts are formed from dry planed wood. Plywood or oriented slabs are placed in the middle of the cake.

It is worth remembering that I-beams will have to be drilled (sawed) a lot, otherwise you will not be able to miss various communications. Attention should also be paid to the vapor barrier of the ceiling in the wooden floor. It is carried out if there is a cold attic on top.

Such a covering is not required under a residential attic. But you still have to cover from the steam the cladding of the slopes and the frame of the rafters. The vapor barrier is made of glassine, polypropylene or polyethylene. Depending on the choice of the installers, these layers are glued or nailed with slats. Only after the vapor barrier is the insulation in the cake. It can be presented:

- various rolls;

- backfills;

- heat-impermeable slabs.

In most cases, the gaps between the beams are filled. Only occasionally do they prefer to lay out thermal protection on a rough flooring or screed. It is recommended to insulate, protect from steam penetration all partitions that are adjacent to the ceiling. Important attention should be paid to the passage of the chimney through the wooden floor. It is required to choose protective materials as carefully as possible. The chimney walls at the point of intersection with the ceiling should be wider than in the main part. Rigid fixation of the groove with overlap is inadmissible. Boxes are insulated:

- mineral wool;

- expanded clay;

- vermiculite.

Exploitation

The service life of a wooden floor can be 50 years (in frame and panel houses). The main risks for him are:

- rotting;

- damage by woodworms;

- mechanical wear of bearing elements.

It is necessary to protect the wooden floor as much as possible from:

- water leaks;

- seepage of precipitation;

- condensation of water vapor;

- unjustified (exceeding the design) load.

For information on how to make wooden coatings with your own hands, see the next video.

The comment was sent successfully.