Strengthening floor beams: features and methods

The technological process of building a house involves the fastening of load-bearing floor beams. They can be made of materials of various strengths, but for a number of reasons require reinforcement. Why beams become unusable and how to restore them, we will tell in this article.

Peculiarities

To date, the following are used in construction main types of floors:

- wooden;

- reinforced concrete slabs;

- metal constructions;

- ribbed;

- Klein overlap.

All of them differ among themselves in the methods of amplification and the material with which the work will be carried out.

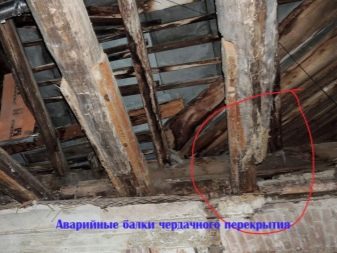

Most often, it is very difficult to detect damaged overlap areas. As a rule, bases made of different materials are located under decorative plaster or covered with false ceilings, painted.

That is why the reinforcement of the floors has to be carried out not quite in a timely manner, when obvious problems with the building structure begin.

There are several reasons why floors should be reinforced to avoid slab cracking, decay or sagging.

- First of all, the reason may be a violation of the very process of installing floors during the construction of a house.

- Another reason is often the use of poor quality materials.

- In the case of metal elements, accelerated corrosion is possible.

- Most often, the reinforcement of floor beams is carried out if they are made of wood. Their deterioration occurs mainly as a result of natural influences, for example, with sudden changes in air humidity or temperature.

- Reinforcement of reinforced concrete floors is carried out due to an increase in the load on the supporting structure, the appearance of cracks, defects during installation or further operation.

- There is a need to complete a floor of a house. As a result of an increase in the load, there is a redistribution of the impact force on all the constituent parts of the base. This is also one of the reasons requiring measures to strengthen the supporting structures of the house.

Repair of floors involves the replacement of some elements with minor defects or reinforcement over the entire area in a critical state of affairs.

The process of strengthening the floor is a rather complicated undertaking, since all work must be carried out in a confined space (inside the building), and it is not possible to mechanize certain operations.

Preparatory work takes a lot of time.

To carry out the whole process, mounting supports are erected under the structure to be strengthened. They are placed vertically. The supporting elements are made of logs or steel pipes and are fixed with spacers or spacers. After that, the surface to be strengthened is cleaned. Remove paint, whitewash, peeling concrete, rotten parts of the beams. That is, they create optimal conditions for the convenience and safety of moving under the ceilings.

Before proceeding to the preparatory, and then to the main stages of work, you should have a certain plan for strengthening the foundations (technological map). It is necessary to know the values of the existing loads and to calculate the number of mechanisms and materials for the implementation of measures for the restoration of existing beams.

It is best to resort to the advice of experienced builders or entrust the work of strengthening the floor beams to a team of specialists.

What do you need to consider?

For each type of floor, there are a number of features that must be taken into account.

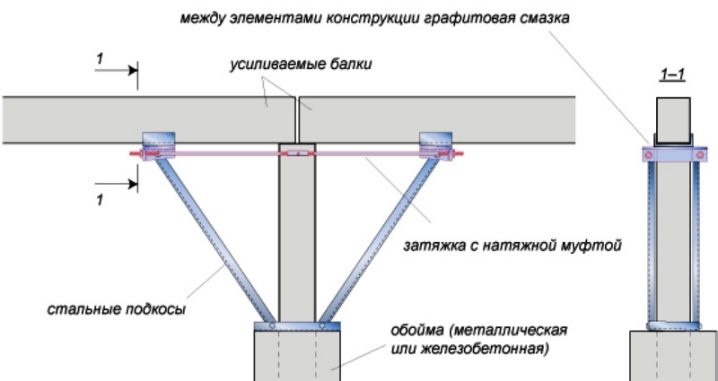

For example, when reinforcing stretched or compressed metal beams, be sure to maintain the original center of gravity. Any additional elements should be positioned so that they do not affect the strength of the original structure.

Welding seams can be deformed. To ensure high-quality operation of additional components with the main reinforced element, the height of the seam leg should be at the level of 3 to 6 mm. Along the edges of the reinforced metal structure, it is necessary to make not intermittent, but continuous seams. Bolts, rivets, reinforcing strips and matched corners should be located in places where it will be convenient to weld.

It is necessary to try to reinforce the floors with materials identical to those of which the main elements are composed, as well as to have an idea of their mechanical properties. It should be understood in what stress-strain state the metal structure is, how it is affected by individual damages. Choose in advance how you need to reinforce the floors and know the technology of the production cycle itself.

Beams made of wood are most often reinforced due to their destruction or deflection. The latter is formed because the structural beam can be a rotten element.

Most often, they carry out a complete replacement of wooden bases or reinforce existing elements. If you plan to increase the mass (to build on, for example, an attic), coming to the load-bearing floor, then be sure to make preliminary calculations. The load on it will change and redistribute, so it is necessary to correct its cross section.

When it is not necessary to carry out a complete replacement, but you find the deflection of wooden beams, you need to take into account the fact that deflection within 10 mm is considered normal... If this parameter is exceeded, then reinforcement of the overlap must be done.

Which method is best suited for this can only be determined by an experienced specialist.

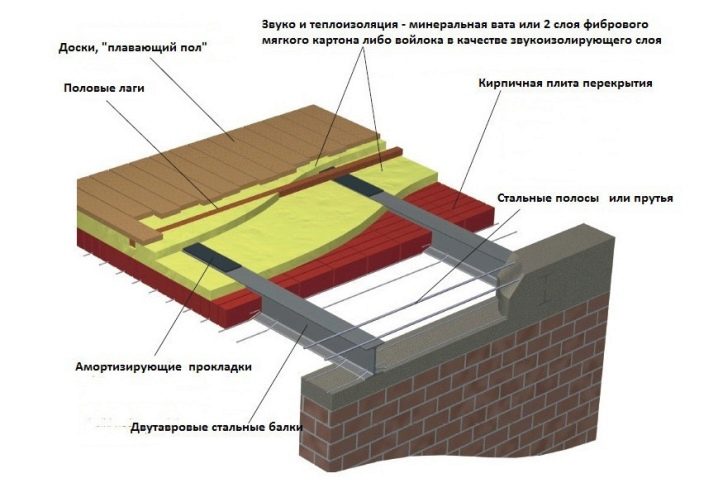

Reinforced concrete slabs are not easy to reinforce; this requires engineering knowledge. Before proceeding with the process itself, it is necessary to take into account the design features of the bases. They are divided into composite and solid structures. Precast panels are usually laid on walls, longitudinal beams or concrete trusses.

Solid floors are made by pouring concrete into a previously prepared formwork, erected above the reinforcing cage. The methods of restoring the loading capacity of different slabs differ from each other.

First, it is necessary to determine the causes of damage. You need to know whether the loading capacity of the slab has decreased due to the fact that it burst or this indicator is lost due to defects obtained during installation, and also whether a complete replacement of the floor is required or it is enough to strengthen some of its parts.

In the process of strengthening, it is impossible to make new mistakes that entail further destruction of overlaps and large financial expenses.

The ways

To strengthen the reinforced concrete slabs in the house, builders use a number of methods in practice.

- Reinforcement bars are reinforced. As a result of corrosion, they become unusable parts. Concrete thickness decreases around them. Rust appears on the concrete surface itself. Before carrying out the reinforcement, remove the concrete layer around the bare rods. They are coated with a coating that prevents the formation of corrosion, after which the entire concrete surface is primed, thereby eliminating the voids formed in the concrete.

- Increase the thickness of the slabs. An additional layer of reinforced concrete is applied.

- The slabs are reinforced from below with steel and concrete reinforcement. Strengthen reinforced concrete floors in the area of contact with the walls of the house.

- Carry out the application of shotcrete (concrete mortar) under compressed air pressure. Such a composition fills cracks and damage spots in floor slabs.

- From below, under separate damaged areas, props are erected, as a result of which the total load on the floors is redistributed.

- If the damage is large, then they carry out a complete replacement of outdated reinforced concrete slabs.

Metal structures are reinforced by increasing the cross-sections of the elements, making additional connecting chains, building up the connection elements, placing ribs, diaphragms or spacers. Often they install additional components to existing structures or change the design scheme.

As practice shows, work is carried out in several ways at the same time.

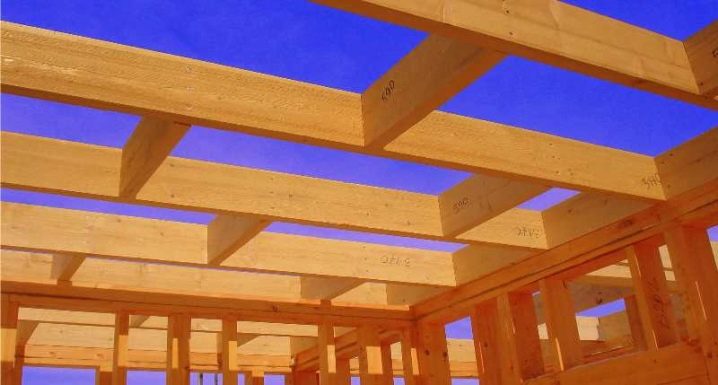

The most common overlap in private buildings is a beam made of timber. If you have a second floor in your house, and the floor began to creak and sag in places, then you should strengthen it.

Wooden floors are the most affordable structures, but their service life is limited in time compared to reinforced concrete and metal bases.

The quality of wood, in addition to climatic factors, is greatly influenced by its processing. Insects and various pests (for example, bark beetles) also help to shorten the life of wooden beams. The material undergoes deformation, crumbling, cracks appear.

There are several ways to renovate wooden floors.

- If the tree is damaged, it is treated with antifungal compounds. After that, the elements can be reinforced with wooden linings. They are fixed at the top and bottom of the supporting beam along its entire length with bolts.

- Reinforcement is also carried out not with wooden, but with metal plates. Steel is used as the metal. The plate itself is pre-treated with an anti-corrosion compound. The metal elements are fixed on both sides of the beam. If there are serious deformations in the wood, it is recommended to use a channel. You also need to worry about waterproofing. It should be between wood and metal structures.

- Fastening with carbon fiber or carbon fiber materials. These can be sheets or plates, tapes, fabric. They are easy to work with. The beam is reinforced by gluing elements to it. Materials are glued in layers until the stiffness of the wooden base increases.

- The ends of the overlap can be reinforced with dentures made of wood or metal. The main focus is on the junction of the wooden floor with the walls. As a result of changing weather and constant changes in air temperature, it is in these areas that damage and deformation most often occurs.

- In order to unload wooden beams, supports from beams are installed under them. Such support pillars take up most of the load from the supporting element.

- Very often, an increase in the number of lags is carried out. Additional wooden beams make it possible to increase the load on the entire structure, thereby increasing the load-bearing capacity of the floor. The ends of the installed lags must be covered with roofing material in order to avoid damage.

As you can see, there are various methods for restoring the functionality of the floors.

The choice of this or that method of work should be carried out taking into account the peculiarities of the structure and materials from which it was erected.

Helpful hints

Specialists dealing with floor reinforcement give advice.

- Ceiling bases have a load limit of one square meter. If the ceiling in the house ends with an attic, then the load on the beams should not exceed 100-105 kg per 1 sq. square meter. When there is a second floor in the dwelling, the overlap can withstand a weight of up to 200 kilograms per square meter. These indicators must be taken into account when installing lags and beams.The entire structure must be with a solid base. You also need to make good thermal insulation, carefully seal up the seams and cracks.

- Before choosing wood for the construction of floors, pay attention to the quality of its drying. Poorly processed and dried wood is subject to rapid drying or deformation. You can't skimp on material. Floor beams should be of the same thickness and length. They should be solid and not consist of several fragments.

- Of course, all the work can be done by yourself., but for this you need to have not superficial, but very deep knowledge in the field of strength of building structures.

For information on how to properly strengthen the floor beams, see the next video.

The comment was sent successfully.