Beam floors: what are they for and what are they?

Beams, located across equal floors, are the main structural element of any building. Additional enclosing functional parts are supported on the beam ceilings. Reinforced concrete, wood, metal, combined materials are used as the material for the beams.

What it is?

Each element of the beam system plays an important role. Parts are usually made of standard sizes, assembled on site using improvised mechanisms. The type of joist floor is always related to the scale of the building. The simplest option is made of wood, suitable for private individual construction. Floor slabs are a structural element of a multi-storey building. The elements are involved in the direct division of the house into floors.

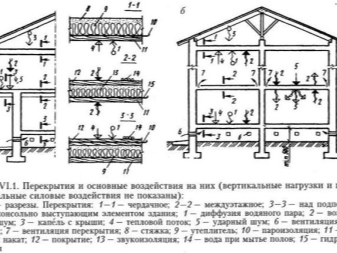

The classic slab is the horizontal supporting structure of the building. In addition to interfloor elements, floors are basement and attic. They are distinguished by their shape into flat and vaulted. The main characteristics of the slabs usually correspond to the requirements that designers, architects, and other persons responsible for the concept of housing are aware of. The classification of overlaps by characteristics distinguishes the following positions:

- by material;

- by appointment.

The role of beamed ceilings in housing construction is high. Without floor beams, floors in apartments will bend even under a slight weight, and ceilings will collapse from ordinary chandeliers. It is a kind of robust skeleton, the appearance of which resembles ribs. This skeleton has been called floor beams for a long time. This main support has always been and is being built with sufficient strength, significantly increasing the weight of the structure as a whole.

True, modern materials are lightweight and have good strength.

What are they needed for?

The beamed floor system does not only carry mechanical loads. It is also a heat-insulating and sound-absorbing layer. It insulates the interior of the house from external influences. For example, it does not allow dampness from the basement, cold from the attic. It is thanks to the high-quality foundations of the joist floor that street sounds do not enter the rooms. In residential low-rise buildings, they are usually of frame type, and interfloor floors look like a solid structure that fits not only between the first and second floors. They are the common skeleton of the structure.

The mechanical load on the floor is measured by the material used and the performance of the building. All parameters are calculated based on certain tasks that are not so easy to perform.

Responsible professionals achieve the right results.

The difference in calculations is associated with the presence of heaters, the types of materials used. The intensity of operation of the attic, storage of things also affect the calculated values.

If an attic is planned in the attic space, the weight of the floor covering, as well as the existing furniture and partitions, is also taken into account.

Depending on the indicators, the floors are prefabricated, monolithic or combined. They are necessary to separate the floors, attic structure or basement from the main room. The main types of joists are usually wood or steel.Wooden beams are inexpensive, but not used in large-scale industrial construction. Disadvantages of the material:

- combustibility;

- decay;

- low strength.

Ceilings are suitable for the construction of wooden structures, low-rise structures, utility structures. In residential buildings of the mass type, prefabricated reinforced concrete slabs and combined panels are used. Elements are subdivided into small- and large-sized. Small slabs are used in private construction or in the construction of low-rise buildings.

Large slabs are needed for very significant structures, in the presence of significant dynamic loads. Sometimes typical slab designs cannot be applied, since they do not provide the required rigidity. For example, if the building being constructed is of a complex shape, the ceiling for it is made to order.

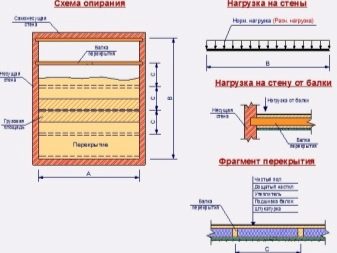

Beam floors have many uses. In the general scheme of the device, the beams not only take on part of the effort, but also transfer it through the walls to the foundation. These are a kind of stiffness diaphragms that create the strength of the structure.

Design features

Optimal design options are selected by developers using special methods. Usually, prices, quality of material, possible labor costs, construction times are compared. This element of the structure for the lower floors is the ceiling. For higher floors, the beams are the floor. The requirements for some types of beam floors are quite stringent.... For example, when it is necessary to carry out division of premises with a temperature difference. The functionality of these structures is almost the same as that of the exterior walls.

The number of total loads on joist floors must be commensurate with the operational characteristics of the building. If the calculated figures are not met, this can lead to defects, the smallest of which is the creaking of the floors. In case of gross violations of work, the building will collapse during operation. The type of overlap must be correctly selected. Only in this way will the reliability of the structure be ensured, as well as comfort while in the house.

Views

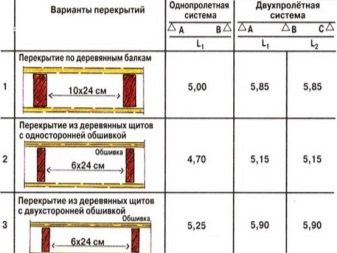

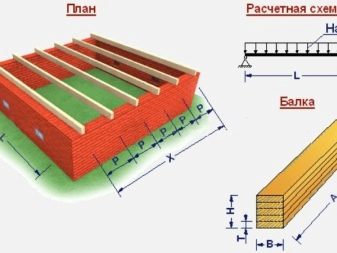

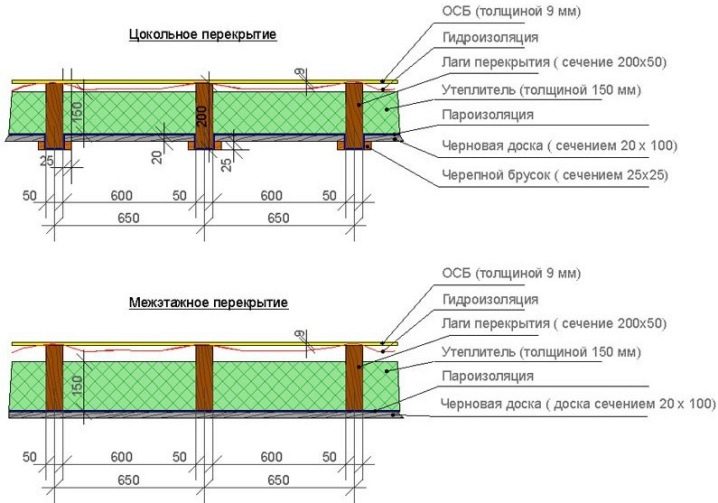

Beam ceilings schematically act as a load-bearing part, and the gap between them is filled with finishing materials for the floor and ceiling. Overlappings on wooden beams are most often made of timber in the size:

- 50*150;

- 100*150;

- 150*150;

- 150*175;

- 175*175.

The peculiarity of wooden beams is that over long distances they provide strength, but do not affect quality rigidity. This defect is eliminated by the correctness of the calculations, but in private construction it is not always possible to carry them out. The recommended pitch for joist floors is 500-600 mm.

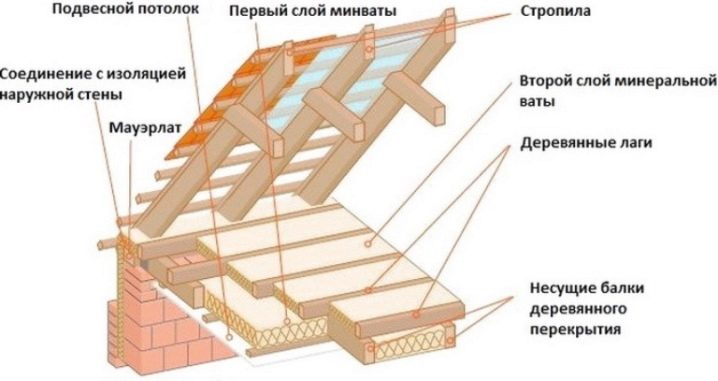

Ribbed decking, of limited use in the conventional sense, has found application in attic structures. They are manufactured with ribs in one or two directions. There is a solid slab at the top. The slabs are connected to each other with anchoring steel joints. They also ensure the unity of the slabs with the vertical load-bearing elements of the building. Steel beams are also divided into types, including:

- assembly;

- semi-assembly;

- monolithic systems.

Channels or T-bars are rarely used in individual construction, although they have serious advantages over other types. The main disadvantage of such structures is their significant weight, which can reach 400 kg. The bearing capacity of the external elements must comply with this characteristic. For example, such parts are not suitable for panel or prefabricated structures made of aerated concrete.

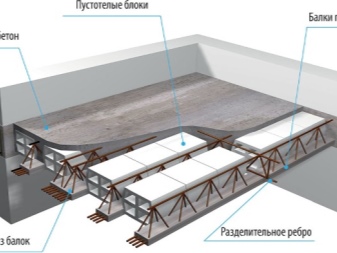

Reinforced concrete structure is rarely practiced in individual housing construction. Technically, it should correspond to the height of the carrier, which should form 1/20 of the gap between the bases. The width of the beam is calculated with a ratio of 5: 7.

The advantage of reinforced concrete structures is that they can be manufactured independently. This is permissible in the presence of formwork equipment, reinforced concrete mix of type 300 and special materials. The reinforced concrete floor is filled with aerated concrete blocks or hollow ceramic stones.

The use of such a system in private housing entails increased labor costs and the economic disadvantage of the project.

However, established technologies are being successfully adjusted. For example, a skeleton on wooden beams can be obtained the same as for metal characteristics. Modification of parameters can be achieved due to a different order of placing the supporting structures.

The beams are arranged in pairs, with a pitch of 500 mm. One part of a pair with large dimensions acts as the basis for the floor, and the other (smaller) plays the role of a supporting element for the ceiling. When creating this system, any vibrations are excluded, and also ideal sound insulation appears.

How to choose?

The length of the beams is selected in accordance with the size of the span to be covered. As a rule, the smallest distance is involved in the calculations if the rooms are rectangular. In the presence of a square, the stacking flow loses its meaning. Especially if the house is made of stone, and all its walls are load-bearing, with sufficient strength. They will withstand bulk not only from timber joists, but also from steel and reinforced concrete structures.

The parameters of the beams are selected from the ratio of the parameters of the existing spans. If necessary, auxiliary elements with large dimensions are introduced into the structure, which rest on parts of a smaller section.

In order to end up with a floor of the same level, the beams in the secondary structure are laid in the supporting bases to the height of their section.

The spacing of the beams does not always obey a single principle. This commitment has to do with the foundations of the walls in which the niches are built. They appear during the construction process, and here their own nuances arise. In some cases, floor beams can be supported by free-standing supports, for example, when the structure is framed. The racks can also be made of wood, such elements are interconnected with special brackets.

If the spans in the constructed building are more than 7 meters, it is recommended to fill them with steel floor beams. These elements are also indispensable for the reconstruction of buildings. For example, steel beams were practiced in the construction of Stalinist skyscrapers. Together with the reinforced concrete monolith, the structures turned out to be very durable and are considered to be of high quality these days.

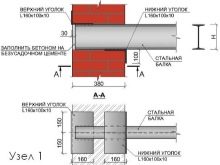

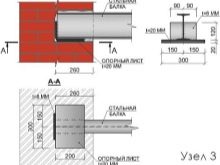

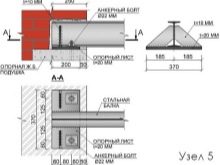

The principle of the arrangement of steel elements is similar to wooden structures. Niche preparation differs in some peculiarities. For example, load-bearing elements need to be protected from uneven division of forces.

It is customary to lay special steel sheets under the steel beams or prepare a concrete pad. Niches are insulated with special materials.

Recommendations

Insulation can be laid directly into the niche, but on condition that it is absent from the wall structure. An open niche can be not only a conductor of cold, but also the cause of moisture and condensation accumulation. It is important to properly insulate it with a suitable heat-insulating material.

Expanded polystyrene is suitable as a heat insulator. The material does not absorb moisture and retains warm indoor air well. When choosing it, it is worth considering the increased flammability of expanded polystyrene, so beware of filling wooden niches with wood beams. In this case, it is preferable to seal the niche with concrete mortar and special non-combustible polyurethane foam. When choosing the last option, it is recommended to wrap the end of the beam with tar paper or roofing felt.

It is highly discouraged to choose a film or a regular plastic bag for the same purposes. Condensation will appear in the closed area from the bag, the wall will freeze. Tar impregnation or any modern antiseptic preparation is suitable as an insulating substrate.This will exclude premature decay of floor beams.

A niche sealed with additional insulation is called deaf. The definition is more common than open construct. In this case, the gap between the beam and the wall is not filled with anything. Materials and labor costs will be saved, but sound insulation is significantly reduced. In this case, waterproofing the wall inside is also necessary, for example, the beams are necessarily covered with protective materials.

You can choose the type of overlap yourself. In this case, it is necessary to take into account the characteristic features of the terrain. Cost-effective options can be selected for each region separately. The important characteristics of the floors are taken into account by the designers. The calculations are individual for each specific structure. Only in this case, you can be sure of the reliability of the structure, which, regardless of the loads, will serve a long service life.

The calculation of a wooden floor is described in detail in the video below.

The comment was sent successfully.