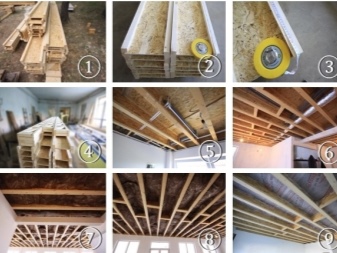

Making wooden I-beams with your own hands

Domestic builders have recently discovered frame construction, which has long been successfully practiced in foreign architecture. In particular, I-timber elements are now widely used both in our country and in Canada, because the climatic conditions are identical, and such beams are excellent for floors. Different variations of such beams are sold on the market, but their price is not always pleasing, although it is acceptable in average values, and many developers prefer to buy beams from manufacturers.

Wouldn't it be more interesting to make the floor beams yourself? All problems with transportation will disappear and there will be no need to adjust the material at the installation site.

You don't always need to be grateful only for what is on the market, if you can make a much more interesting final product yourself.

It makes no sense to describe the deep details of the production of the beams themselves, since every builder, even when installing ordinary racks, has his own method and methods of construction, his own set of tools and understanding of the issue. The article gives a general idea of \ u200b \ u200bmaking do-it-yourself wooden I-beams.

Material selection

This is one of the key points in the work. There is a difference between wood and wood, and a lot will depend on what kind of beams are obtained and what is more rational to use in construction.

- Bar. The best timber is glued, so it deforms least of all and is less likely to rot and swell. This building material is a favorite of manufacturers, who praise its properties and durability in numerous advertisements. But it is always worth remembering that even the most durable material cannot exclude the absorption of liquid over time.

- Larch. The species of the selected tree is also important. It is very difficult to work with the lower crown of any log house, so here, as our ancestors did before us, larch is just perfect. Although it is a coniferous tree, it has a special resin that gives the wood its distinctive properties - it will become stronger when wet. But it is important to protect the crown from moisture as much as possible.

It is worth noting that the minimum section of the timber for the formwork that can be allowed will be 35 mm. The timber should be of large cross-sections to avoid unnecessary consumption of wood.

What tools are needed?

In addition to the standard tools required in construction, for this work, emphasis should be placed on two components.

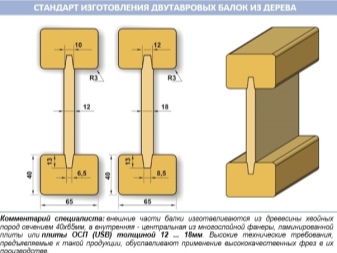

- Rack. There is not a lot of choice here - you can take both plywood and the main options - chipboard or OSB sheets, which are significantly superior to fiberboard in terms of technical characteristics. There are many alternatives on the market, but the old school is better. It is advisable to focus on particle boards - they are more reliable and durable.

- Glue. As a rule, few people take into account that the choice of glue also plays a significant role, especially when working with wood. Toxicity is extremely undesirable here, and therefore the more natural and safer the adhesive composition, the better, especially when building a house or other residential complex (cottage, summer cottage).

Manufacturing

When the bars are ready, you need to do the sawing in order to subsequently make an even vertical stand.

Examine each slab carefully, there should not be even the slightest defect, otherwise the beam will not be able to support the weight. Don't be afraid to reject.Yes, the money spent on the stove can be a pity, but much more money will have to be thrown away if the entire structure is damaged.

The selected slabs must be slightly beveled at the edge so that they fit exactly into the groove.

Lubricate the cuts with glue and press the upper to the lower. Wait until the glue is completely dry: the waiting time should be described in the instructions.

High-quality joining of all elements of an I-beam can be ensured by trimming purlins from a channel of the same length. They must be placed on the beams, and pulled together with a rope or scraps of dense fabric, if there is enough appropriate length, and wait until the glue is completely solid. Only after the glue is ready is the beam ready for use.

In the manufacture of the supports themselves, no problems should arise.

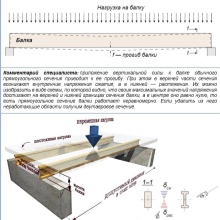

The most important thing is to make all the necessary calculations, do not hesitate to ask for advice, and if it does not work out, contact professional builders, even with calculations. You cannot take risks here, since the overlap is the beginning of the beginning of any structure, and violation of the correct parameters is fraught with injuries and the collapse of the house.

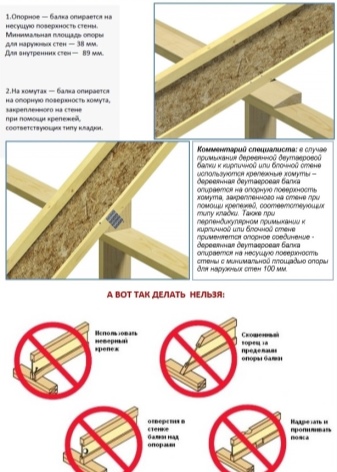

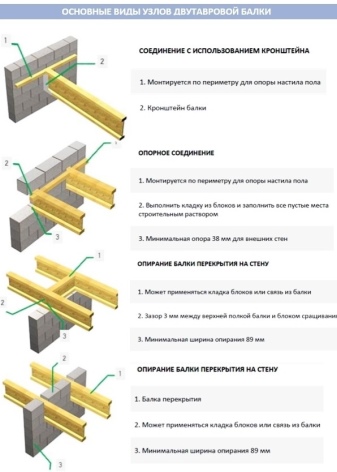

Typical mistakes

Let's figure out what needs to be considered in order not to make dangerous oversights, and what can go wrong in the production of beams.

Mistake # 1

Purchase of unprepared raw materials. If you decide to independently make I-beams for overlapping, then you need to remember that under production conditions everything is made using a special technology, and calibrated dry fittings are used, which prevents the beams and boards from twisting and acquiring irregular shapes.

Mistake # 2

Purchasing and using inappropriate or too cheap glue. For example, as attractive as the choice of resin adhesive is, it is an absolute no when working with I-beams. Epoxy resin has very poor adhesive properties and takes too long to cure.

The best choice of glue is polyurethane. It is thermally active, but does not ignite itself, and this is very important when working with wood.

Of course, it is worth noting that PVA glue will not work, no matter how magical adhesive properties it has. The Moment glue is also inappropriate in this case.

Mistake # 3

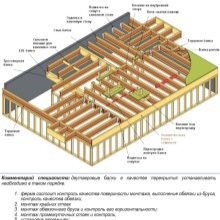

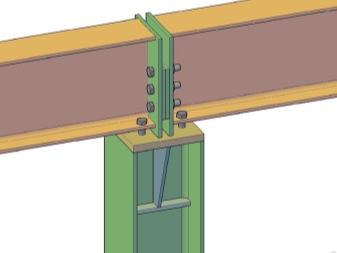

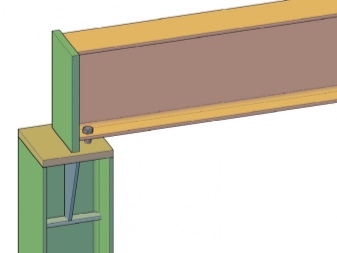

Incorrect mating of the beams themselves. Here you need to understand that these are not simple wooden, but I-beams, and it is a big mistake to overlap them. They must be attached end-to-end and secured with plates.

Do not use perforated tape so that the beams do not tip over later. You need to use accurate calculations using the calculator.

Mistake # 4

Using the wrong fasteners. The most awkward thing seems to be the use by builders of polyurethane foam for filling holes. The bookmark must be strictly special. It is recalled to use the wrong dougun, this will violate the load-bearing capacity of the floor, and the entire structure may collapse.

Ordinary screws are also not used in relation to I-beams, since by themselves they do not withstand serious loads. It should be remembered that screws are not structural parts - they can only attach something light in weight. Also pay attention to the dougun - if its height is insufficient, then it cannot be used. Size matters too - a small bracket is not acceptable.

Mistake # 5

The use of third-party parts not provided for by the design. There is no need to reinforce anything just “for insurance”. Conventional I-beam fastening is already tight and does not require unnecessary parts. The figure shows typical installation errors.

Helpful hints

Should not be neglected general recommendations, tips and notes.

- Do not use the same I-beam for floors, change it.

- Calculate loads accurately. To do this, you can use different online calculators or do the calculation yourself.

- When in doubt, it is best to seek professional advice.Do not allow the beams to be placed crookedly - this can stop the entire construction and ultimately endanger the structure.

- All wood is subject to high-quality drying. This will help to avoid possible deformation in the future, because it is not known how the products were stored before they came into your hands, in which warehouses they were.

Of course, you can simply use the timber in different parts of the frame, but this is not always beneficial from the point of view of economy. Making an I-beam with your own hands and using it is technologically more rational.

It is when we combine OSB sheets and timber that we get the most durable and durable structure, optimal in terms of its building characteristics:

- heat and frost resistance;

- resistance to loads and weather conditions;

- relatively light weight.

Although you can always combine various elements of a homemade I-beam and configurations for a variety of frame needs. Therefore, and especially with regard to construction, you should always try and not be afraid to make a mistake. Making the decision to build something with your own hands is a reason for great pride, because for many years you will admire the fruits of your labor.

But if you decide to build something on your own, you need to approach this responsibly from the very foundation, because it is from it that the whole structure will continue to begin, and everything should be perfect from the base so that the structure is strong and even.

How to make wooden I-beams, see below.

The comment was sent successfully.