Ribbed floor slabs

Construction of facilities is impossible without high-quality materials. The supporting structures must be strong and withstand heavy loads. Floor slabs are as important in construction as foundations and walls. One of the important elements are ribbed floor slabs. They are distinguished by good strength, the ability to evenly distribute heavy loads.

Features and purpose

Without overlaps, no object can be considered complete. The correct choice of slabs predetermines and guarantees the safe operation of the house, even in areas of seismic activity. It is important to plan the load vectors correctly, as they must be evenly distributed on the load-bearing walls and on the floors themselves. The correct selection of materials is also important, because the strength of the object and its resistance depend on them. Ribbed slabs are ideal elements that can support a lot of weight, while at the same time they make it possible to create quite large spans.

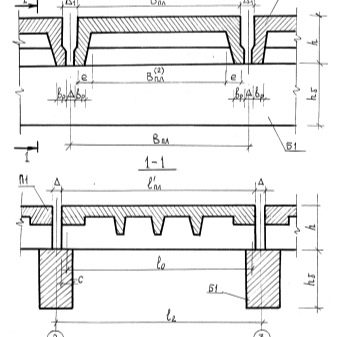

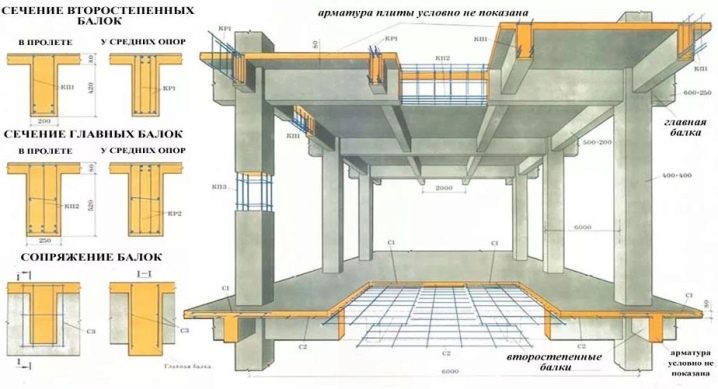

Ribbed floor slabs have an important feature. The reinforced concrete structure has a solid base, ribbed elements allow it to withstand heavy loads that "work" in bending. If the loads are too high, then the concrete monolithic slabs are reinforced with transverse ribs.

In places where there are no loads (or they are minimal), the concrete is removed. At the points of high loads (compression zones), concrete is added. Thus, prefabricated ribbed plate receives maximum strength, the ability to withstand heavy loads, while the amount of material is noticeably reduced.

The spacing of the floor slab with beam elements does not exceed 6 meters. The ribbed slab can be roofing or part of the basement floor. In residential buildings, such attic floors are not so common; they are usually used in industrial facilities.

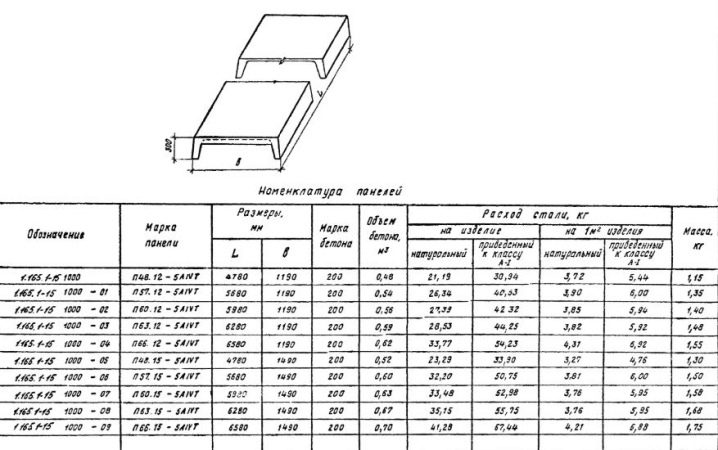

Light, heavy or dense silicate concrete is used as a material. Depending on the grade of concrete, reinforcement of different formats is also used, which is marked with a special designation (letters and numbers).

The information that is present in such records is quite enough to operate with it during the compilation of load calculations.

Specifications

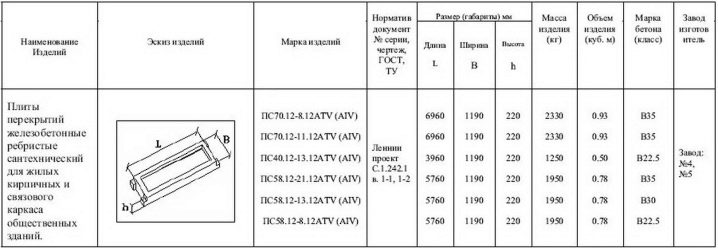

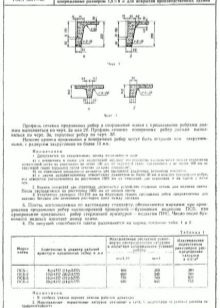

Modern reinforced concrete plants use a variety of types of concrete in their production, according to GOST 28043-89. There are the following types of ribbed slabs:

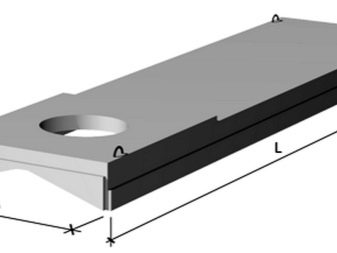

- PG - without any openings;

- PV - plates with holes for ventilation equipment;

- PF - various lamps can be installed in the slabs;

- PL - slabs that are intended to remove the roof.

Important! Technical data in relation to ribbed slabs (height 0.41 m) are prescribed in GOST 26215-86. The classification and differentiation in this document is prescribed taking into account which point of the crossbars the product rests on.

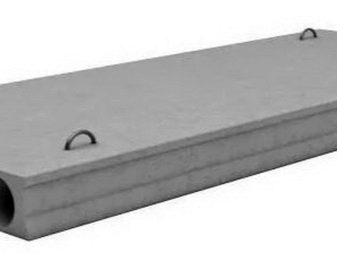

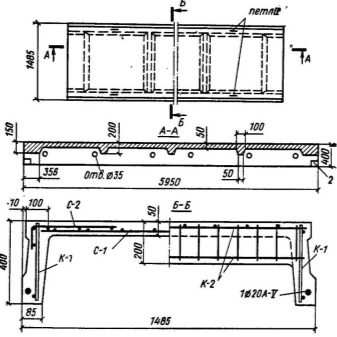

When installing heavy slabs, a crane is mandatory. The product should rise to a great height without any distortions, parallel to the horizon line. To comply with the technology of lifting a multi-ton slab, special metal "ears" are used. These elements are important, they must be strong and reliable, according to safety regulations, they are checked for defects or cracks. Ribbed slabs are measured according to the following parameters:

- length;

- thickness;

- height;

- the weight.

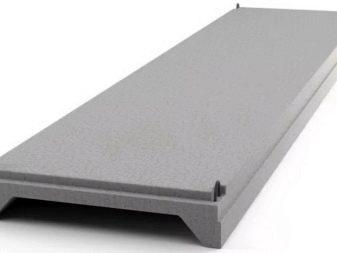

The height of the products is 22.2 cm. Sometimes, upon request, the manufacturer can make the thickness of the slabs 17 cm.Elements differ in the parameters of technological holes and different coefficients of sound insulation. The length of the slab can vary considerably - from 2.2 to 12.5 m. The most common dimensions can be from 3.65 to 7.25 m in length.

Sometimes the manufacturer makes reinforced concrete products to order. In this case, additional reinforcement is required, since the mass of the product increases. In such cases, you should calculate: is it possible to do without transverse ribs (they give the product a greater stiffness coefficient). The width of the ribbed slabs can be as follows (in meters):

- 1;

- 1,25;

- 1,51;

- 1,81.

Ribbed slabs are most often rectangular. In the form of a square, such products can be seen infrequently, while the price for them is noticeably higher. According to GOST, the dimensions of ribbed plates are as follows (in meters):

- 3x12;

- 3x6;

- 3x18;

- 1.5x6.

The weight of the ribbed slabs varies. It ranges from 771 to 825 kg per square meter. In structures with heavy loads, small-sized products are used that can withstand up to 2.5 tons per 1 square meter. The load scheme is different, the most common are the following:

- constant;

- short-term;

- evenly distributed;

- unevenly distributed.

The standard unit for calculating loads is the number of kilograms per square meter. The quality of the boards is subject to such stringent requirements as:

- dimensions must comply with GOST;

- all parameters comply with strength standards;

- there must be good resistance to temperature and humidity changes;

- have good resistance to cracking and deformation;

- all elements made of metal are processed by "Antikor".

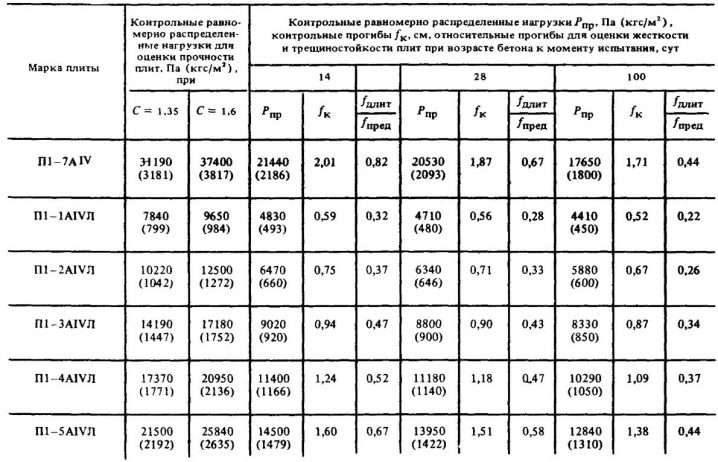

The concrete must meet certain parameters. Density - from 1810 to 1990 kilograms per square meter. At the same time, there must be a porosity that meets all approved GOSTs. Heavy concrete in terms of density can reach 2550 kg. The tension of the reinforcement is measured after the concrete has "grabbed" (there are different standards here). Heavy concrete can be labeled M455 or M650. Lightweight concrete can be M250 and M300.

Steel is used for reinforcement only of those grades that are also provided for by GOSTs. All configurations of metal elements must be consistent with the project. Tension indicators can deviate from the norms by no more than 10 percent.

If you comply with all the norms prescribed in the standards, then the configuration of ribbed reinforced concrete slabs allows you to withstand significant loads for a long time without any interference.

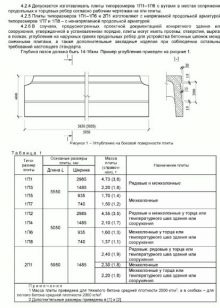

Plates are produced in accordance with standards of 300 and 400 millimeters in height. Sizes can vary markedly, but there are still generally accepted norms. If the height (the main feature and distinctive feature of the slabs) is 300 mm, then its length reaches 5.68 m, and its width is 0.939–2.96 m. Based on this, reinforced concrete slabs can have the following dimensions:

- 3x6 m;

- 3x12 m;

- 1.6x6.1 m;

- 3x18.1 m;

- 1.6x12.2 m.

Important! Plants admit slabs that are made from a variety of concrete, from ultra-light to super-heavy.

The weight at a height of 300 mm can be as follows:

- 1.18–3.09 t (lightweight concrete);

- 1.46–3.87 t (heavy concrete).

If the height is 400 mm, then the plate has the following parameters:

- length - from 5.1 to 5.98 m;

- in width - 0.75–2.976 m;

- 1.4–3.9 t (lightweight concrete);

- 1.39–4.78 t (heavy concrete).

Important! The fittings must be pre-tested.

Places of arrangement of slabs can be in the following variants:

- in standard rows (P1);

- in the intervals between the bearing columns (P2);

- in a single closed node, which "gathers" bearing walls and columns together (P3).

Types

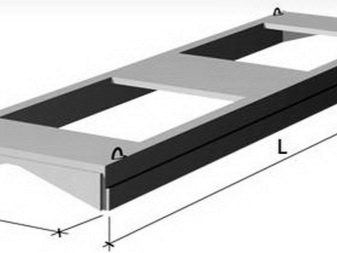

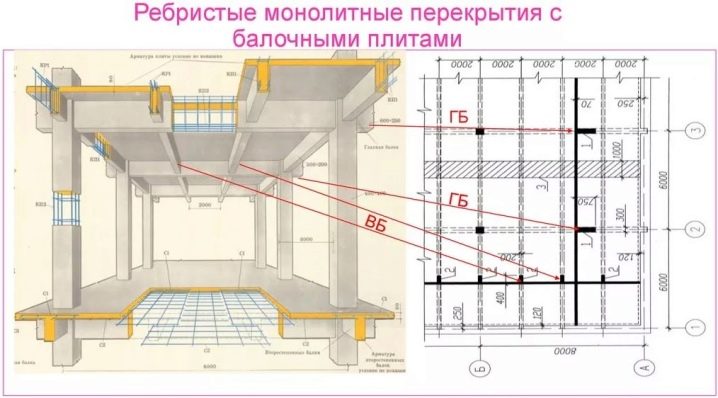

Some of the most popular reinforced concrete slabs are products that resemble the letter "P" in configuration. Such designs can be found at various facilities, mainly in industrial areas. The spacing of the bearing vertical supports is no more than 6 meters, in this case the floor slab will withstand significant loads.U-shaped slabs are in greatest demand, since the configuration of the product realizes the ability to evenly distribute the load.

The longitudinal ribs of the slabs act as a beam that takes the lion's share of the weight. In this case, the work takes place on a bend. After installation, the material must be tested for strength and rigidity.

In the manufacture of U-shaped slabs, concrete with a density of 1820–2050 kg per cubic meter (lightweight grades) is used. Heavy concrete can reach a density of up to 2500 kg / m³. It is a reliable material that can withstand significant loads. When preparing the concrete, all prescribed standards must be observed.

PG slabs have standard dimensions (in meters):

- 3x6;

- 3x12.

They are used on roofs in places where, presumably in winter, there can be a significant layer of snow (more than 155 kgf / m².) Ribbed U-shaped plates have an arrangement of transverse ribs every meter, if the width is 3 meters. If the width is two times less, then between the ribs - 1.5 meters. The thickness of the shelf is 32 and 36 cm. The structures have embedded inserts so that various elements, for example, parapets, can be attached to the walls. Ventilation equipment can be placed on perforated plates. In total, standard holes are of the following sizes (in millimeters):

- 410;

- 710;

- 1000;

- 1455.

As for the reinforcement, in ribbed slabs, it begins to experience lower loads after the concrete reaches a certain hardness, which is provided for by GOST. In this case, the material must be prepared in accordance with regulatory requirements. All metal elements must meet the stipulated standards. Deformation of reinforcement after test loads should not be more than 10 percent.

If the value exceeds the permissible standard, then such a product is not recommended.

The mortar should be applied 2 cm thick just before the board is lifted. It takes 2 people to put the stove in the right place. All gaps that form during the installation process must be sealed with cement mortar. The mixture is made in a ratio of 1: 3, where 1 is the amount of cement, 3 is the amount of sand... The sand should contain a large percentage of clay, then the solution will be more plastic.

Sometimes it is necessary to make a non-standard hole in the slab, in this case a special tool is used. The weight of the slab is on average one and a half tons. It is required to store it on a flat surface, the plates must be shifted with bars, a gap of at least 50 mm remains between them. Such storage methods prevent products from deformation, as well as the effects of changes in humidity and temperature.

Marking

The letters and numbers that can be seen on the plates are markings that indicate the weight and parameters of the product. From this abbreviation, you can find the following information:

- what concrete is it made of;

- what kind of fittings are used;

- what is the strength factor.

In order to understand how the marking "works", it is recommended to get acquainted with the symbols of the P-1 plate. We see 2P1-3, ATV-I P-1. The first three values are the size and type of the product, the last digit means the division of floor blocks into load-bearing elements that can withstand certain loads. Next, there is a decoding of the characteristics of the reinforcement. The letter P is nothing more than lightweight concrete. In conclusion, the last figure is a designation of the design features of the slab, namely:

- 1 - one more mortgages are installed in the product;

- 2 - ribs (on the sides) have holes with a section of 210 mm;

- 3 - similar holes, but have 215 and 710 mm.

Reinforced concrete ribbed products, designated by a combination of symbols P2-ATV-N-3, are deciphered as follows:

- P2 - standard size marking;

- ATV - reinforcement characteristics;

- H - denotes standard conditions, without any force majeure;

- 3 - indicates the presence of a ventilation hole with a diameter of 0.8 meters.

Load calculation and installation

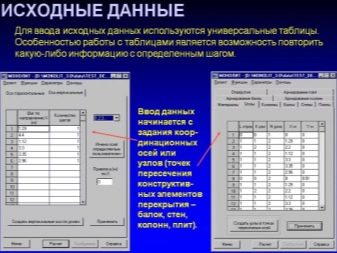

The calculations of ribbed plates are carried out in our time using special software. The following basic data is required for correct costing:

- lateral forces;

- bending impulse;

- torque;

- seismic hazard;

- what kind of snow cover can there be;

- what kind of ground the object is on.

A load diagram is drawn up, in which the following is determined:

- overlap parameters;

- steel grade and number of reinforcement;

- allowable span parameters.

If everything is done "according to science", then the picture will be completely transparent, it will become clear: what kind of loads can be subjected to the overlap. Based on the data obtained, it will be possible to find out the following for sure:

- what concrete to make;

- what density and weight the product should be.

The calculation is made in kg / m². The baseline value for a residential building is 400 kg / m². A slab height of about 12 cm creates a load of 255 kg / m². The screed on the floor can be 110 kg / m². These basic loads are distributed along the walls of the facility. Plates simultaneously give rigidity and stability to the entire object, which greatly increases its durability and resistance.

In this case, insurance is important, therefore it is recommended to lay an additional strength factor of ½. That is, the final figure of the maximum permissible load will be about 900 kg / m².

The most popular are the following products:

- IP 1 weighing 2228 kg, the cost is 14,895 rubles;

- IP 2 weighing 2027 kg, cost - 23625 rubles;

- IP 3 weighing 1500 kg, cost - 18,055 rubles;

- IP 4 weighing 1378 kg, cost - 45820 rubles;

- IP 5 weighing 2375 kg, cost - 39390 rubles.

Installation of slabs is done by the following method:

- when laying the slab, a layer of cement mortar is applied to all end planes, you should work only with fresh mortar so as not to violate the strength of the joints; if the solution is in a diluted state for more than 1 hour, then it will lose its performance characteristics;

- the overlap should rise horizontally to the top of the horizon line, so the fastening at the four corner points should be identical;

- during work, the crane operator is assisted by two workers (slingers), who must correctly fix the plate; personal protective equipment and the necessary tools must be present;

- there are slopes in the slab (technologically they are permissible); if the difference between the upper and lower planes reaches 7 cm, then the gap is filled with a cement compound;

- metal hinges are fastened with reinforcement, the edges are bent and welded; sometimes it is necessary to fix additional fasteners;

- from the outside of the object, an edge (150 cm) remains, on which brickwork will be carried out.

To correctly install the product, you should study the technical regulations. Ribbed slabs can be differentiated into types such as:

- tent;

- cavity;

- long.

Monolithic slabs are sometimes used. They are expensive and add strength to the structure. Ribbed slabs meet all the requirements for such indicators as sound insulation and thermal conductivity. The following tools and materials are required for laying ribbed slabs:

- cement;

- sand;

- fine gravel;

- truck crane (with a lifting capacity of 3-5 t);

- sledgehammer;

- puncher;

- trowel;

- plastic and metal buckets (15 liters);

- turbine;

- two-meter German or Russian level;

- scrap;

- gypsum composition;

- welding machine;

- heat insulator;

- fittings "8" and "10";

- heat insulating material;

- welding machine;

- garbage bags;

- corners "4" and "6";

- water level.

Before mounting the slab, you should prepare the plane. It should be flat, while differences are permissible, but not more than 20 mm. The water level should carefully measure the base between different corners of the object, ideally one should coincide. A properly prepared surface is the key to a long service life of the building. It is imperative to take into account the mobility of the soil. If the soil is swampy or the object is in a lowland, then deformations of the structure are possible.

It is most reasonable to put the stove only on capital structures. Most often, partitions are made indoors when the floor slabs have already taken the place reserved for them. For fastening in the joints, special clamps are provided. All gaps are filled with technical cotton wool and coated with plaster mortar. Before installing the plates, you should draw a diagram of their installation in stages. It is also recommended to check all dimensions again. There should be a minimum amount of gaps.

Important! To avoid deformations, the slab should be placed simultaneously on two load-bearing walls.

Choosing ribbed slabs as floors, you should rely, first of all, on the calculations made. They will tell you which products are best to use in the given circumstances. Ribbed slabs have a large margin of safety. If you choose them correctly, then they will serve for a long time.

For information on how to properly install ribbed floor slabs, see the next video.

The comment was sent successfully.