Expanded polystyrene: advantages and subtleties of using the material

There are many requirements for building materials. They are often contradictory and have little to do with reality: high quality and low price, strength and lightness, professional results in solving narrowly focused tasks and versatility. However, some materials fit the bill. Among them is expanded polystyrene. Having studied its advantages and subtleties of use, you can successfully use the material to solve various construction problems.

What it is?

Expanded polystyrene is the latest generation of building materials. Its production uses innovative technologies, so it is difficult to guess its predecessor. And expanded polystyrene "evolved" from the familiar to all polystyrene - a material that protects household appliances from damage during transportation.

The main properties of the foam - lightness and cellular structure - have been preserved. Inside the expanded polystyrene boards there is a huge amount of air-filled granules. Its content reaches 98%. Due to air bubbles, the material has low thermal conductivity, which is so appreciated in construction.

Water vapor is used in the production of foam. This makes the material porous, granular and brittle. Polystyrene foam is foamed with carbon dioxide, therefore its characteristics have been improved. It is distinguished by:

- high density per cubic meter;

- less porous structure;

- appearance and structure on a cut;

- higher price.

Expanded (extruded) polystyrene goes through eight production stages:

- Fire-fighting substances - fire retardants - are added to the raw materials. Also, dyes, plasticizers, clarifiers are used.

- The finished composition is loaded into pre-foaming equipment.

- Primary foaming and "aging" of the mass takes place.

- "Sintering" and shaping. The molecules of the raw material adhere to each other, forming strong bonds.

- Processing on special equipment, which is necessary to give the substance its unique properties.

- Final foaming and cooling.

- The substance is stabilized and the surface is sanded to a smooth state.

- Slab cutting and sorting.

The result is a material that is mainly used as insulation.

Features: pros and cons

Extruded polystyrene has advantages and disadvantages as a building material.

Pros:

- Wide range of applications. It is used for indoor and outdoor work on various surfaces: floor, walls, ceiling, as an insulating, packaging and decorative material. In addition to the construction industry, its use is widespread in the production of toys, household appliances, household appliances, and the military and medical industries.

- Low thermal conductivity. Due to this property, polystyrene often serves as a heat-insulating material. It prevents heat loss in the room, which affects heating costs. The better the insulation, the cheaper it is to heat the house.

- Low coefficient of moisture permeability. Inside the material there are sealed granules, into which a minimum amount of water penetrates. It is so small that it is unable to destroy the structure of the material and negatively affect its insulating qualities.

- Improves indoor sound insulation.To achieve the maximum effect, you need to combine it with other materials, however, in a room where the problem is not pronounced, it will be enough.

- Easy to cut. During the installation process, the slabs can be divided into fragments. The cut will turn out to be even, it will not crumble. This is the hallmark of quality material.

- It has a relatively low weight. One pair of hands is enough to work with the material. In addition, the advantage of light weight is that the polystyrene sheathing does not put a lot of stress on the walls or floors in the room.

- Easy to mount. No special skills are required to decorate walls, floors or ceilings.

- Resistant to many chemicals.

- Insensitive to the effects of living organisms. That is, mold does not form on it, insects and rodents do not spoil it.

- Due to its internal structure, it belongs to the "breathing" materials. This is important when decorating walls, as condensation does not form.

- Levels any work surface. A decorative coating fits well on top.

- Polystyrene boards can be glued directly to the wall of a building (or other surface) without mounting a crate for this. This reduces the time and financial costs of repair work and simplifies them at times.

- The minimum service life is 15-20 years.

- Low cost of finishing per square meter.

Minuses:

- Thermal insulation of a large area of walls, ceiling or floor will be expensive even with a low cost of material per square meter.

- For maximum tightness of the finish, additional materials may be needed in the form of construction tape and sealant.

- The polystyrene sheathing does not regulate the room temperature by itself. It works on the principle of a thermos: it keeps warm in the cold season, keeps it cool when it is hot. If the room is poorly adjusted thermoregulation, then the efficiency of polystyrene is zero.

- Despite the "breathing" ability of the material, with continuous sheathing of the house with expanded polystyrene, installation of ventilation is required.

- The material is afraid of ultraviolet radiation. Under the influence of sunlight, internal bonds in the structure of a substance are destroyed, and natural conditions accelerate the destruction of extruded polystyrene.

- Some types of paints, substances based on petroleum products, acetone, gasoline, kerosene, epoxy resin corrode expanded polystyrene.

- A decorative finish on top of polystyrene foam is required to close all the seams and protect it from the sun's rays.

- The density of the material is greater in comparison with foam, but polystyrene loses to other materials according to this criterion. It is more suitable for finishing ceilings and walls, and shrinks under the floor covering under constant point mechanical action (walking, rearranging furniture).

Specifications

To comply with building codes, the technical characteristics of the material are important. These include: brand, overall dimensions of sheets, thermal conductivity, moisture absorption coefficient, flammability according to fire safety class, strength, service life, storage method. The technical characteristics are not of paramount importance are the color and texture of the boards.

The sizes of sheets (plates) of expanded polystyrene are calculated according to three parameters: length, width, height. The first two indicators are the same if the slab is square.

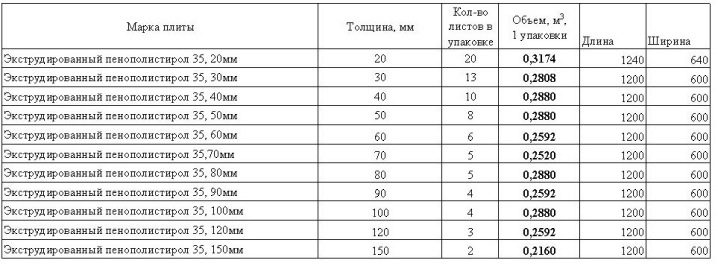

Standard dimensions of slabs are 100 cm wide and 200 cm long for sheet material, 100x100 for slab. With such parameters, GOST allows a size greater or less than the norm by 1-10 mm. Non-standard, but popular sizes - 120x60 cm, 100x100, 50x50, 100x50, 90x50. The material is easy to cut, so you can adjust the parameters to suit your needs yourself. Permissible deviations from the norm of non-standard sheets - up to 5 mm.

For thickness, these indicators are more stringent, since thickness is the main criterion for choosing polystyrene foam. It is variable for different types of repair and construction work.Minimum values: 10, 20 mm, 30, 40, 50 mm. The maximum is 500 mm. Usually 50-100 mm is sufficient, but upon request, some manufacturers can produce a batch of non-standard thicknesses. According to building codes for most regions of Russia, the required thickness of polystyrene insulation is at least 10-12 cm.

Thermal conductivity is one of the most important indicators. It is determined by the thickness of the air gap inside the slab of the material, since it is the air connections that make it capable of retaining heat inside the room. Measured in watts per square meter and in Kelvin. The closer the indicator is to one, the less its ability to retain heat in the room.

For slabs of different thicknesses and densities, the thermal conductivity index varies in the range of 0.03-0.05 W / sq. m to Kelvin.

Some manufacturers use graphite additives. They stabilize the thermal conductivity in such a way that the density ceases to play a role.

A good example of the effectiveness of expanded polystyrene is a comparison with mineral wool. The thermal insulation properties of mineral wool are considered good, while thermal insulation of 10 cm of polystyrene gives the same result as a layer of 25-30 cm of mineral wool.

Density

Measured in kg / sq. m. For different types of polystyrene, it can differ by 5 times. So, extruded polystyrene has a density of 30, 33, 35, 50 kg / sq. m, and shockproof - 100-150 kg / sq. m. The higher the density, the better the performance characteristics of the material.

It is almost impossible to measure the strength parameters of a material on your own. You need to pay attention to the certified data. Normal compressive strength is 0.2 to 0.4 MPa. Bending rate - 0.4-0.7 MPa.

Manufacturers often state that the moisture absorption of the material is zero. In reality, this is not the case, it absorbs up to 6% of moisture that gets on it during precipitation and washing the facade. The combustibility of expanded polystyrene is also controversial. On the one hand, the addition of pyrene makes the material resistant to fire, on the other hand, this does not mean that the fire extinguishes when it collides with the material.

Polystyrene melts quickly enough. At the same time, high-quality material does not emit pungent smoke, and melting stops 3 seconds after the fire goes out. That is, other materials cannot ignite from expanded polystyrene, but it supports combustion. Grades from K4 to K1 are assigned to different brands. Materials of the K0 brand are considered as safe as possible, but expanded polystyrene does not apply to them.

Other important parameters:

- Water vapor permeability. For different types of polystyrene, this indicator is 0.013 - 0.5 Mg / m * h * Pa.

- The weight. It starts at 10 kg per cubic meter.

- Temperature range of use: lower temperature threshold -100, upper +150.

- Service life: at least 15 years.

- Noise isolation - 10-20 dB.

- Storage method: in a sealed package, away from sunlight and moisture.

- Grade: EPS 50, 70, 80, 100, 120, 150, 200. The higher the grade, the better and more expensive the material.

- Colour. The most common colors are white, carrot, blue.

Varieties

Polystyrene is divided into varieties according to four main criteria: structure, method of production, purpose, area of application.

Structure

By structure, atactic, isotactic, syndiotactic expanded polystyrene are distinguished.

It makes no sense to delve into the complex structural formula of substances. It is important for the buyer to know only that the first type is the most productive and widely used in private and large-scale construction, the second is distinguished by the greatest strength, density and fire resistance and can be used in rooms with increased fire safety requirements, and the third type is universal due to its chemical stability, density and heat resistance. It can not only be mounted in any type of room, but also be coated on top with all kinds of paints and varnishes.

Method of obtaining

According to the method of obtaining, there are a greater number of types of polystyrene. The most common is extruded polystyrene foam, since it has all the qualities necessary for construction. But there are other ways of production as well. Changes in some stages and composition of raw materials make it possible to obtain materials with different characteristics. Some are less dense, but flammable, others are the most durable and fire resistant, others are not afraid of moisture, and the fourth combine all the best qualities.

There are eight ways in total, two of which are outdated. For almost a century history of polystyrene and its derivatives, emulsion and suspension methods have lost their relevance.

In modern conditions, the following are produced:

- Extruded polystyrene foam... Foam material with fine, uniform granules. Carbon dioxide is used instead of harmful phenols.

- Extrusion... Almost the same as extruded, but it is used mainly in the food industry (packaging), therefore, among its properties, environmental friendliness is more important than strength.

- Press. It undergoes an additional pressing procedure, therefore it is considered more durable and resistant to mechanical stress.

- Bespressovoy... The mixture cools and solidifies on its own inside a special mold. At the exit, the product has a convenient size and geometry for cutting. The procedure does not require intervention (pressing), therefore it is cheaper than pressing.

- Blocky. Products obtained by conversion (several processing cycles at the same stages) are distinguished by high indicators of environmental friendliness and the highest possible quality.

- Autoclave. A kind of extruded material. In terms of properties, it practically does not differ, only other equipment is used for foaming and "baking".

Appointment

According to the purpose, expanded polystyrene is also different. Cheap, but high-quality general-purpose polystyrene has become widespread. It does not differ in mechanical stability and density, is considered fragile, and has the smallest fire safety class. However, the material is rigid and holds its shape, which makes it possible to use it in cases where no mechanical load will be carried out on it: lighting equipment, outdoor advertising, decoration.

For more complex tasks, high-impact polystyrene foam is used. In addition to the fact that the material is less brittle and non-combustible, it contains substances that are responsible for UV resistance and color pigments. UV stabilizers protect the structure from destruction, and the color from fading and yellowing.

High-impact polystyrene boards have a surface of different texture: smooth, corrugated, matte or glossy, reflective and light-scattering.

High-impact foil polystyrene foam should be noted separately. It has increased frost resistance and is more effective as a heater. It is also used in the manufacture of refrigeration equipment, since its "thermos properties" (to keep the temperature inside the object) is higher than that of other types. Impact-resistant polystyrene is used in many areas: the production of toys, dishes, household appliances, finishing materials.

Application area

The categorization of expanded polystyrene by areas of application is more extensive. There are several areas: for the food and non-food industries, for rough and decorative finishing, for indoor and outdoor work.

For food products (lunch boxes, containers, substrates, disposable dishes), polystyrene with environmentally friendly additives is used. Similar raw materials are used in the production of the non-food industry (children's toys, refrigerators, thermal containers). In the manufacture of toys, more dyes and components are added that are responsible for the strength of the product.

Rough finishing can be internal and external. In all cases, polystyrene is used to prevent heat loss and / or improve sound insulation in the room. Less commonly, it is used to level the work surface.

Indoor polystyrene is used in repair and construction work for cladding various surfaces.

In residential premises:

- For the floor. On the entire surface of the subfloor, polystyrene slabs are mounted when there is a need to insulate a floating or dry screed. For this, the material is sufficiently flat and dense, contributes to heat and sound insulation. You need to choose strong and dense slabs that can withstand a lot of weight per square cubic meter and have maximum compressive strength. The advantage of using expanded polystyrene plates for screed installation is that this material does not give such a large load on the floor as a monolithic screed. Relevant for old rooms with weak ceilings and for bases with high moisture absorption, on which it is difficult to pour a monolithic screed (in a block or wooden house).

Also, polystyrene provides a perfectly flat surface for installing the floor covering. It is a waterproof underlay for laminate, parquet and other types of hard topcoats.

In addition to the fact that the slabs cover the entire surface of the floor, it can be used locally. For example, as a vibration damping base for a plinth in a floor soundproofing system.

- For the ceiling. Properties such as density, strength, light weight and comfortable shape make the material suitable for soundproofing ceilings. No frame lathing is required under it, the material can be glued directly onto the glue, and the voids can be filled with a non-hardening sealant. Two layers of slabs mounted in spacing will give a noticeable result in the fight against extraneous noise in the apartment. It is convenient to mount a suspended ceiling or glue decorative tiles on top of a flat sound-proof cushion. The tile, in turn, is also a polyurethane derivative with decorative treatment.

- For walls... Polyurethane is rarely used in the decoration of vertical surfaces indoors. Errors during installation lead to the fact that efficiency is reduced to zero, and the room loses in volume not only visually - the useful area of the room also suffers. However, sometimes polyurethane is used for wall cladding indoors, in order to align them or erect a light partition inside the room and divide it in half.

- For roof... Here we are talking about the insulation of the roof from the inside. This option is relevant for living quarters in the attic and for thermal insulation of the attic in the bath. Expanded polystyrene simultaneously retains heat, prevents condensation and requires minimal waterproofing efforts. Foil-clad polystyrene is considered the best option for finishing the attic.

- For pipes. Pipes and risers of various communications are protected from freezing by means of sheet foil-clad polystyrene of small thickness. The same technique helps to improve sound insulation.

In some cases, polystyrene is used to create decor in the interior of residential premises. Tiles, ceiling plinths, decorative rosettes, moldings, false portals for fireplaces are made from it.

In vestibules and utility rooms (on the street-house border):

- for a balcony or loggia;

- for the veranda and terrace;

- for the basement.

In all cases, frost-resistant foil polystyrene foam is used, which prevents excessive heat loss and does not allow the room to heat up too much in hot weather.

As for the external finish with polystyrene, it can also be rough and decorative. Roughing is used for the foundation, facade and the manufacture of permanent formwork. Decorative - only for facade decoration.

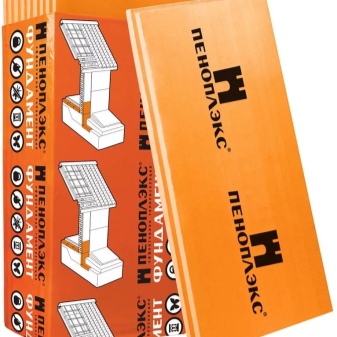

Insulation of the foundation from the outside protects it from freezing, cracking and partly from groundwater.The influence of these factors is taken over by polystyrene, which significantly reduces its service life. It is wiser to mount the slabs from the inside (if the foundation is tape), so it will last longer.

Facade cladding of residential and non-residential premises using polystyrene in order to improve thermal insulation is possible in three ways:

- Installation on a frame or frameless wall decoration outside the room. This makes it possible to competently organize waterproofing and vapor barrier if necessary, reduces heat loss, increases sound insulation. Such cladding can be dismantled when renovating the facade.

- Well masonry, which is carried out simultaneously with the erection of the walls of the building. In this case, polystyrene is "walled up" into a brick or block wall and serves as a heat-insulating layer.

- Simultaneous decorative and heat-insulating cladding. It is possible when using SIP panels and ventilated decorative panels for the facade. Outside, the panels are made of polymers, and inside there is a thick layer of polystyrene. The structure is mounted on a crate. The result is a beautiful, high-quality, efficient two-in-one finish.

Separately, it is worth noting the possibility of external cladding of buildings using polystyrene. First, it can be dyed and easily trimmed. And secondly, decorative elements of the facade are made from this material: cornices, columns and pilasters, platbands, thermal panels, 3-D figures. All elements look neat and realistic, and are several times cheaper than analogues made of plaster, stone and wood.

Manufacturers and reviews

The production of polystyrene began at the beginning of the last century and is developing at an active pace to this day, therefore, the products of many competitive companies are presented on the market. Feedback from professionals and ordinary users helped identify leaders among them.

Ursa Is the only manufacturer that legally provides a product warranty for up to 50 years. If during this period negative changes occur with the material, which are fixed in the warranty conditions, the company will reimburse the losses.

Ursa polystyrene is chosen due to the fact that for an affordable price you can buy a product that meets all the technical requirements for exterior and interior decoration. It is moisture resistant, high strength, does not freeze, absorbs only 1-3% moisture, is easy to cut and convenient for installation. The production uses only natural gas and materials that comply with the European standard. This makes polystyrene safe for humans and the environment.

Knauf Is a German manufacturing giant that manufactures products for all types of finishing work. Often appears on the list of market leaders due to consistently high quality and guarantees. Heavy-duty expanded polystyrene is used in all areas, from the food industry to medicine. He is even trusted in the decoration of municipal premises and public places.

On the territory of the Russian Federation, Knauf polystyrene is actively used in the repair and construction of metro stations in the capital.

The products of this manufacturer differ in price above average, but they fully justify themselves.

The three leaders are closed by the universal heat-insulating material from the company TechnoNICOL. Innovative technology, economy and high quality combine in the XPS range. The manufacturer is domestic, so the product is available in the lowest price segment.

Also among the popular brands are marked "Penoplex" and "Elite-plast".

Tips & Tricks

In order for expanded polystyrene to serve for a long time and cope with its functions, it is important to choose the right material and fix it to the working surface with high quality.

It is recommended to use specialized glue for fastening. It does not contain acetone, resins and petroleum products that will corrode the material.

When choosing polystyrene, manufacturers advise taking into account several factors: brand, density, weight, strength.The higher these indicators, the better the quality of the material. But with flammability and thermal conductivity, the opposite is true - the closer the indicator is to zero, the better the material will show itself in operation.

You need to check this data in the accompanying documents, otherwise there is a great risk of acquiring a fake.

Without examining the certificates, you can check the quality with a little trick. It is necessary to break off a piece of expanded polystyrene from a solid sheet and look at the scrap: if it is even, and the cells are small and of the same size, the material is solid. Poor-quality polystyrene crumbles and shows large cells when broken.

For the benefits of expanded polystyrene, see the next video.

The comment was sent successfully.