What is asbestos fabric and how to care for it?

Asbestos cloth is a fine-fiber material from the silicate group. "Asbestos" in Latin means mountain or indestructible flax. Asbestos fabric is made on a loom by weaving yarn fibers. She, the yarn, is represented by asbestos fibers and cotton, lavsan or viscose threads that bind them. There can be 5-18% of such threads in the fabric.

Origin story

The fabric appeared in Antiquity, when people saw non-woven fibrous fabric, very similar to rotted wood. From it they got the idea to weave a canvas. And then it became clear that the resulting fabric is not subject to combustion. The nobility, who did not skimp on the scale of the feasts, preferred to cover the tables with tablecloths made precisely from asbestos fabric. And this is logical: there is no need to wash them, but you can just throw the amazing material into the fire. And then, get out of the flame a clean and completely unharmed tablecloth, ready for a new service.

By the way, for a long time people in general did not understand how this was possible, while others used it. Even Charlemagne did not consider it shameful to show his surroundings this trick with asbestos thrown into the fire. The impressed viewers were sure that the ruler could even cope with the flame, and, therefore, he was also a magician. Over the years and centuries, the demand for asbestos fabric is only growing. They are already making hats, gloves, towels and much more from it. Needless to say, knightly armor did not do without asbestos fabric, which made them fireproof. Asbestos was used to make curtains in theaters, bakers sewed aprons for themselves from such fabric as glassblowers and blacksmiths, for example, used it.

Today, asbestos fabric is produced in different parts of the world: in the USA, Canada, India. At the moment, the method of its production has been improved, viscose or lavsan can be added as binding elements. Naturally, there is a lot of research going on about the potential hazards of asbestos. And the topic, indeed, is not unfounded: in a number of countries it is banned as a material capable of causing oncology.

True, for this for a person to receive such risks, asbestos fibers must enter the lungs in high concentrations. And this already applies only to those categories of people who constantly work with asbestos. In production, therefore, new, perfect levels of protection for employees are used. But asbestos as a building material is considered harmless and non-toxic. Therefore, the fabric is used as a heat-insulating or cushioning material, as a basis for workwear and other purposes.

How is the canvas made?

The largest deposits of asbestos are recorded in the States, France, Japan, Russia and South Africa. Before you take the material for further manipulations, you need to comb it out well, in a special way. The fabric is made by both transverse and longitudinal weaving. In addition to asbestos, other fibers are added to the fabric, the total percentage of which will not be higher than 18. If cotton or viscose is added, the guarantee period of the fabric is 5 years, if it is polyester fiber, it is extended to 10 years.

Important! Chrysotile asbestos or magnesium hydrosilicate is used for the production of asbestos fabric.The substance is layered, containing bundles of very thin fibers that are incredibly tear-resistant.

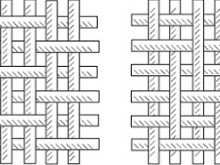

After combing these long natural fibers, a binder is added there, twisted into a thread called asbestos yarn. And on the looms, the fabric is woven from this yarn. Weave as simple plain weaving, and rep and twill. The surface of the fabric is rough.

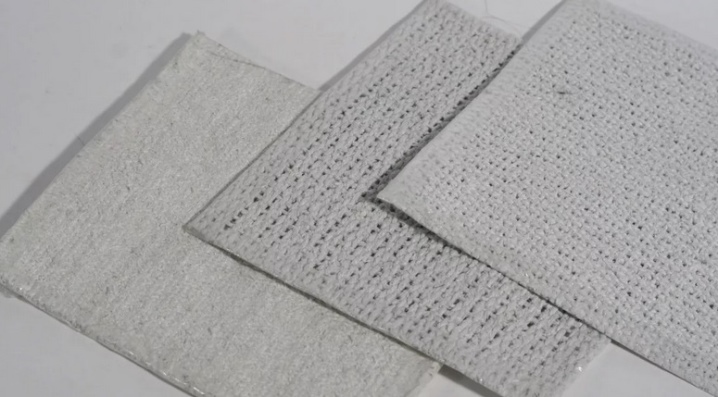

The manufacturing plants produce asbestos cloth in rolls of various sizes. These can be both standard sizes and original ones, which are agreed in advance with the customer. The weight of one roll should not exceed 80 kg. The natural color of the canvas is white with a slight sheen, but it can be yellowish-green and yellowish-brown. However, if the customer so wishes, the fireproof fabric will be repainted.

Main characteristics and properties

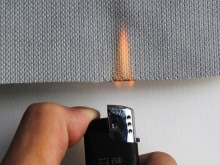

The main property of the fabric is fire resistance. This is, in fact, the only material of this kind that can guarantee protection against fire, that is, a fire-fighting material with a natural composition in the base. There are quite a few advantages of the material, it:

- fire resistant and heat resistant;

- durable and resistant to wear;

- frost-resistant;

- has good thermal insulation characteristics;

- not afraid of fungi and rotting;

- resistant to alkalis and some acids;

- has low sound conductivity;

- differs in affordability.

Are there technical drawbacks to the material? Yes, it was not without them. For example, asbestos cloth needs special disposal. The harm from it mainly concerns only professionals who have to constantly contact with fabric. Asbestos dust particles, as mentioned above, can settle in the lungs.

But professionals are protected by a special uniform. The same material that goes on sale and is used for various construction works must comply with GOST and be certified.

Species overview

In construction, asbestos is used more than widely. There are several varieties of it.

AT-4

When used, it can withstand temperatures up to +400 degrees, contains up to 82% of mineral fibers, and as a binder means brass wire. It is a material of increased strength and density. Used in extreme conditions.

AT-2

The operating temperature is also +400 degrees, the mineral fibers in the fabric are 81.5%. The binder is cotton. It is used in the production of asbestos laminates. This is the name of a compressed product, which does not consist of one layer of asbestos cloth and is impregnated with resin. Its scope is thermal insulation in industry, as well as making the object more durable.

AT-7

Withstands temperatures up to +450 degrees, and the amount of mineral fibers in it is 90%. It is used as a cushioning and heat-insulating material.

AT-3

Virtually identical to AT-2 material. Cotton is also added to its composition. Good material for industrial equipment products.

Other

Cloth A-5 is also close to A-4, it also includes brass wire, the scope of application is the same. AT-1 correctly write AT-1C, the temperature of use is +400 degrees, mineral fibers in the composition of at least 85%, cotton is selected as a binder. AT-6 can withstand temperatures of no more than 100 degrees, and the amount of mineral fibers in it is 95%, the material is used in the production of diaphragms for water electrolysis.

AT-8 and AT-9 are similar in composition and application to AT-7. AT-16 - fabric with at least 95% asbestos in the composition, suitable for a temperature regime of 100 degrees. It is used as a diaphragm in water electrolysis, as well as in the production of fabric expansion joints.

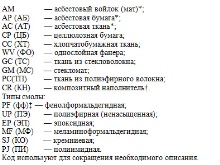

Marking

Asbestos cloth has its own characteristics that correlate with its performance properties. They are spelled out in GOST 6102 94. For each brand, according to this standard, there must be its own parameters, which include surface density, thermal range of use, ultimate loads and the number of threads per 10 cm, parameters (width and thickness indicators). What should be on a roll tag of any brand:

- manufacturer;

- name of the fabric and its brand;

- roll width;

- the number of the batch in which a particular canvas was produced;

- date of manufacture;

- standard and technical conditions;

- letter T.

Of course, you can buy such material only from a trusted seller who has all the necessary documents for it. The material is specific, therefore any fake will cost the buyer too much.

What is it used for?

Chrysotile asbestos is the most popular asbestos fabric. And the scope of its application is very wide. Here are just a few examples of areas where asbestos cloth is used.

- Roofing and wall products. If you add asbestos to cement, you get an asbestos-cement fabric that is very strong. It can be realized in sheets.

- Facade slabs, pressure (and non-pressure) pipes of different diameters.

- Filters, cords, as well as fabrics, cardboard - and other similar materials that are used for thermal insulation and technical needs.

- Rubber products. For example, to make a rubberized fabric, you can add asbestos fiber to it with cotton and rayon in the formula.

- Asphalt concrete mixes, drilling and construction solutions.

Overalls are made of asbestos for extinguishing a fire, for fire blankets and blankets, for welding. Such a refractory product can be used for chimney, for winding a muffler, and not just for welding or fire extinguishing. In brakes, for example, asbestos is used as an anti-friction element. In industry, it is actively used for filtration. It can be involved in the production of plastics, insulators, scraps. Asbestos is also actively used to insulate stoves and other heating devices.

The main property of this fabric is to protect a person from the effects of high-temperature sources.

Care Tips

Rules for the use and storage of fabrics begin with safety measures.

- The room in which work is carried out with asbestos cloth must be equipped with forced ventilation, and ventilation must be powerful. With the help of ventilation equipment, particles of asbestos must be completely removed from the space.

- When working with the canvas, you must be sure to wear closed clothing and thick gloves. Contact of matter with skin and mucous membranes of a person should be minimized.

- The canvas itself must be stored in an enclosed space. Well, if this is not possible, and it remains in the open air, you will have to come up with something to protect it from moisture. Otherwise, the fabric will not work.

- Asbestos cloth can be transported in virtually any way, but only on the basis of a complete and high-quality packaging of the material in polyethylene. Sometimes fabrics are moistened in a certain way during transportation so that dust particles of asbestos are not released into the air. But more often a good, tight package is enough.

- Drying of asbestos fabric should be carried out at intervals of at least 1 time in 3 months. The cloth should be cleaned of dust at the same frequency.

The correct storage of the fabric is very important: the closable cases and covers that are inaccessible to water will help to quickly use the fabric in the event of a fire.

Therefore, it must often dry out so as not to cease to retain its properties. In Russia, asbestos cloth is used and produced, despite the fact that many countries have abandoned it. But they have not yet found a worthy replacement for it, and therefore they leave it in production. It remains to keep track of new research, and the fabric that has to be used now is operated with all precautions.

The comment was sent successfully.