Facade dowels: types, sizes and characteristics

The use of insulation helps to reduce heat loss through walls by 15 - 20%. For high-quality installation of thermal material, special connecting products are used. Facade dowels are designed for attaching thermal insulation to the outer walls of public buildings and residential buildings. They are also used as fasteners for various structures.

What it is?

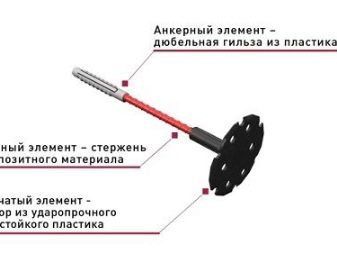

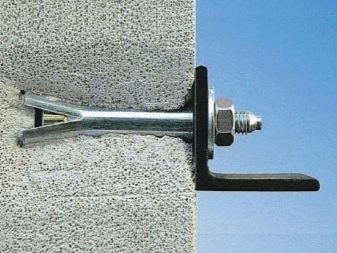

The facade dowel is a fastener consisting of a spacer, a retainer and an anchor. The spacer part is made of fiberglass and serves as a rod for various fasteners. The design of the spacer part fixes the fasteners in one position.

Depending on the purpose, the structure can be with a screw or a nail. The screws are coated with an anti-corrosion layer. The nails are protected against corrosion by galvanizing. Thanks to the latch on the base of the dowel, it does not sink into the hole. A plastic retainer presses the thermal insulation material. The larger the diameter of the retainer head, the better the hold. The anchor is located at the bottom of the structure, looks like a sleeve with grooves. The anchor plug is made of polyamide.

The facade dowel is characterized by a long rod that serves to clamp the material of great thickness. For a more reliable fixation in the depth of the bearing wall, structural elements can be equipped with notches and antennae.

With the help of front fasteners, insulation panels, guides of a wooden and aluminum profile, hinged structures, brackets, and a frame of a prefabricated facade are fixed.

The use of dowels helps to avoid loosening and falling out of nails and screws from the drilled holes.

Specifications

The manufacture of facade fasteners must comply with the standards of GOST 56707-2015 for facade thermal insulation systems. According to the requirements, the products must be fireproof, resistant to climatic influences, shock-resistant and frost-resistant.

Dowels for facades are characterized by the following indicators:

- There is a high degree of adhesion to any base material.

- Products are resistant to temperature changes from -40 to +80 degrees.

- The plastic base does not react to moisture, the metal rod undergoes anti-corrosion treatment.

- Reliability and rigidity of fixation is guaranteed by anchoring and spacer structure.

- Polymer elements and thermal head rods have low thermal conductivity.

What are they?

Facade dowels differ in several ways:

- material of manufacture;

- structure;

- application;

- dimensions.

Facade fasteners are made of artificial polymers. For each individual fastener part, a different composition is used as raw material. Polypropylene and nylon can be used as the material of manufacture. Nylon dowels are completed with a metal rod. They can withstand loads from 200 to 400 kg on various substrates.

Nylon is durable, abrasion resistant, does not crack from sudden temperature changes, does not stretch. Polypropylene fasteners will not be able to withstand a load of more than 70 kg, they are afraid of temperatures below -20.

By structure

The type of construction determines the external structure of the individual dowel elements. Depending on the size of the retainer, a poppet and anchor type of structure are distinguished. Anchors are used to fasten structural elements to the facade.The anchoring structure consists of a nylon or polypropylene dowel with a screw.

The screw head can be of different shapes: straight slot, cruciform, hexagon.

The front anchor of the Tech-KREP TSX PRO brand has a slot made in the form of a six-pointed star. The anchor facade dowel is firmly fixed in the hole with the help of stiffening ribs, the edge petals do not allow the fasteners to move in a circle. The RDF type dowel has a stopping flange, the RDR type without flange will help to deepen the anchor into the material. The use of Mungo MBK S TB fasteners will allow you to increase the downforce without damaging the base using a locking screw with a press washer.

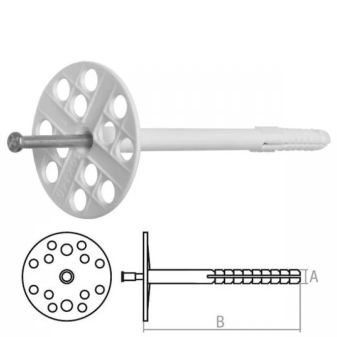

Heat-insulating materials are fixed with dish-shaped facade structures.

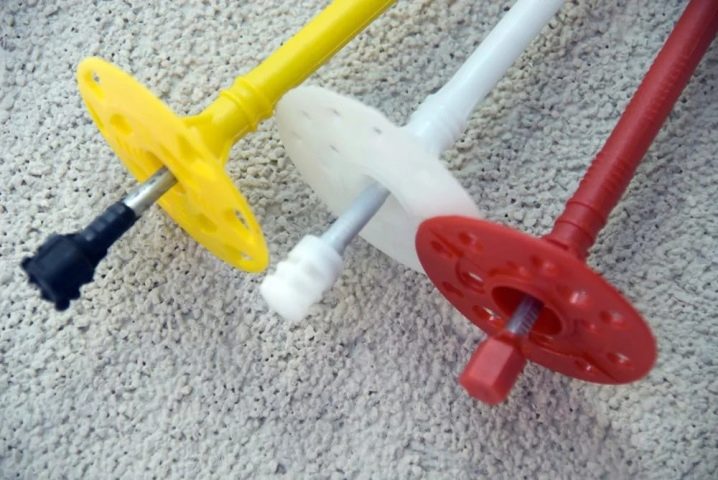

There are three types of disc fasteners:

- with a plastic nail;

- with a metal nail;

- composite.

In fasteners with a plastic nail, a polymer pin acts as a rod. The raw materials for its manufacture are nylon, polystyrene, basalt plastic. Dowels with a plastic nail fix light insulation to the base of hollow brick, foam concrete, gas silicate. The fastening efficiency will remain if the dowel length does not exceed 16 cm.

Using this type of fastener has many advantages:

- They are not afraid of moisture, which eliminates the appearance of rust.

- The minimum weight does not bear the load on the supporting wall structure.

- The low coefficient of thermal conductivity of plastic will not lower the temperature at the point of attachment.

- The products are of low cost.

The dish-shaped construction with a metal nail is durable and reliable. They are used for fixing heavy-weight insulation on dense concrete bases. The nail is made of steel, often the surface is galvanized or coated with an anti-corrosion compound. The size of the fastener can be up to 30 cm.

A metal rod reduces the thermal insulation properties of heaters in the place of fasteners, since it conducts low temperatures well. To reduce thermal conductivity, nails are equipped with a thermal head made of polyamide materials. The thermal head on the base of the nail does not allow the cold to pass deep into the wall, additionally protects the metal of the case from rust.

Composite dowel is a fastener with a fiberglass rod, additionally equipped with a washer. The anchoring part is 6 - 10 cm, which allows you to install fasteners in any base. The length of the entire structure can be up to 60 cm, suitable for any layer of insulation. Using a washer, the diameter of the retainer is increased to 10 cm.

By application

Facade dowels are mainly used for mounting a curtain wall and fixing insulation to the wall. For fastening the thermal insulation, disc-shaped joints are used. Facade anchors are used to fix canopies, brackets, mounting battens and rails made of wood or metal. The frame dowel is used to assemble door frames and window frames.

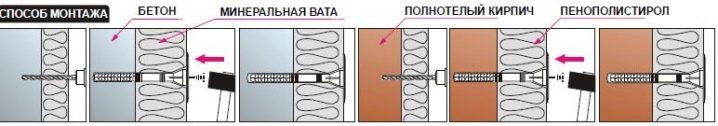

The use of different types of fasteners depends on the base material. Dowels with an anchor zone of 4 - 5 cm are used for fixing in brick and concrete. For aerated concrete and foam blocks, the anchoring part is 6 - 7 cm. The rod can be plastic or metal. When installing on hollow bricks or plaster, the length of the anchor should be up to 8 cm.

By size

The dimensions of the fastener are the sum of all parts of the constituent elements. The standard dowel diameter is 1 cm. The retainer head for the disc design is 6 cm in diameter. When using an additional 1 x 80 mm clamping nut, the fixing area will increase.

Each product is marked with the dimensions of the fastener.

The length of the front dowel is selected based on the thickness of the insulation. If the thickness of the insulating layer of the wall is 70 mm, then the size of the dowel should be 10x120 mm. A 19-20 cm layer of mineral wool will hold 10x240 fasteners.

The average thickness for insulation foam or extruded polystyrene foam is 5 cm.They are fixed with disc dowels with a plastic nail 10x100 mm or 10x115 mm in size. The size of the rod will be 8x100 mm.

Manufacturers rating

Dowels of foreign and domestic manufacturers are presented on the Russian market. In terms of quality, Russian production is catching up with foreign counterparts. The difference between them is primarily in the price.

A popular supplier of facade anchors to the market is a fiberglass plant in Biysk. The products are characterized by low thermal conductivity due to the fiberglass material of manufacture. The assortment of products consists of fasteners of various lengths with an anchor zone of 50 and 80 mm and a section of 1 cm, 5 mm, 7 mm, designed to fix any heaters in bases of different densities. The standard diameter of the cap is 6 cm.

About a quarter of the fasteners market is occupied by the Tech-Krep trade and production association. The company manufactures products with izo plastic nail, izm galvanized nail, izl impact resistant polyamide head, steel nail and izr protective cover. Different lengths of the rod are capable of fixing the insulating layer from 5 cm to 24 cm. The anchoring part is from 4 to 6 cm.

For fastening thermal insulation up to 15 cm, fasteners with a plastic nail are used. Metal nails are used for materials up to 24 cm thick. The protective thermal head prevents corrosion during the subsequent plastering of the facade.

Front dowels are presented on the market under the Termozit trademark with a multi-colored thermal head on a galvanized nail. The polyethylene head on the rod prevents corrosion and cold bridges at the attachment point. There are models of products with anchor base from 40 to 70 mm. The length of the structure varies from 95 to 300 cm.

The Russian company "ELEMENTA" specializes in the production of anchor facade fasteners of four brands. The EFA-F modification is distinguished by the presence of a high-strength galvanized screw. The grades EFA-FН and EFA-FСН have screws with a corrosion-resistant coating with a strength of 6.8 and 8.8, respectively. The EFA-FA4 brand represents products with a stainless steel screw.

Foreign manufacturers on the domestic market are represented by the brands Sormat, Mungo and Fischer. Fischer, a German company, supplies façade dowels with a nail, screw and hex washer. The fasteners are made of nylon and comply with European requirements for mounting products.

The Finnish manufacturer Sormat produces products with an increased wedge area. This allows the material to be securely attached to any surface. A spacer with a 115 mm screw with a hexagon in the base is designed to secure consoles and brackets.

A well-known supplier from Switzerland is the Mungo company. It offers three varieties of its products to the market. For fastening to solid concrete and brick substrates, a dowel with an MBR screw rod is suitable. With a larger anchor area, MV hollow support fasteners are available. The universal design of the MQL brand is capable of fixing thermal insulation on any base due to four wedges of different distribution.

How to choose?

The strength of the installation of the facade structure and thermal insulation materials will depend on the correctly selected fasteners.

The choice of a particular facade dowel will depend on:

- base material;

- dimensions and type of thermal insulation;

- climate of the area;

- altitude.

The base for fastening can be made of aerated concrete, solid brick, sand-lime brick, concrete, hollow brick, plaster, wood, foam concrete. Each material has its own density, on which the strength of the connection depends. The more porous the base, the greater the length of the anchor zone of the fastening hardware with the reinforcement of the spacer, supplemented by notches.

The size of the spacer and the length of the rod will differ from the thickness of the insulation. If the insulation layer is 4 cm, then the length of the dowel should be taken 9 cm.With a maximum insulation thickness of 24 - 25 cm, a 30 cm long rod is suitable. The anchoring depth varies from 4 to 6 cm.

Lightweight polystyrene and polyurethane artificial insulation materials are attached with a plastic nail structure. Mineral wool, capable of absorbing and retaining water in the structure, is fixed with dowels with a metal rod, preferably with an anti-corrosion coating and a thermal head.

In order to securely fix various thermal insulation materials on the facade of buildings, it is necessary to select facade fasteners in accordance with the climate conditions in the region. In case of frequent windy and stormy weather, it is necessary to increase the length of the anchor part of the dowel. With a large weight of thermal insulation, increased fastening is provided per square meter of the structure.

For low-rise private construction, universal dowels with a standard load are suitable. With a larger number of floors, the fasteners for the facade must have increased technical characteristics of structural strength and strength to be removed from the base.

When choosing dowels for the facade, their cost is not a determining factor. It depends on the basis of raw materials, the size of the purchase batch and the technical parameters of the products. The price of one unit of the product varies from 3 to 55 rubles. The number of pieces is determined by the area of the mounting area.

To buy durable suitable dowels, on average, you can spend 300 rubles for 10 square meters. The total cost of fasteners, in comparison with facade finishing materials, is the lowest.

Material tips

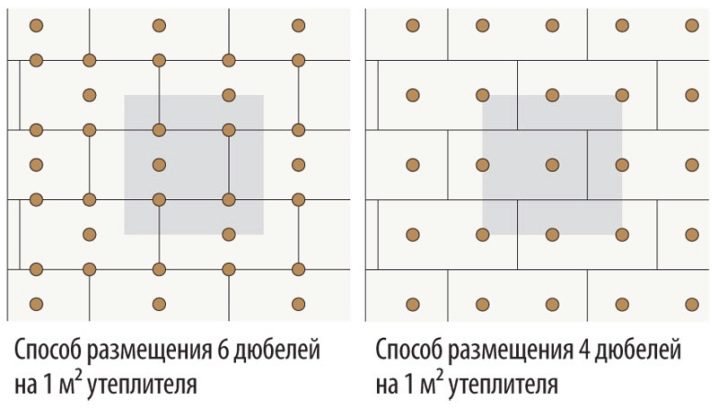

The installation of the facade dowel is not difficult and can be done independently. Insulation of external walls and facade finishing should be carried out in dry weather at temperatures from +10 to +30 degrees. It is necessary to carry out a preliminary calculation of the number of facade dowels. It depends on the weight and size of the insulation panel, the number of sheets of material, the area of the facade.

With different installation options, from 4 to 10 fasteners are consumed per square meter. To increase the degree of pressure of the thermal insulation material to the wall, the fastening element is placed at the junction of the plates.

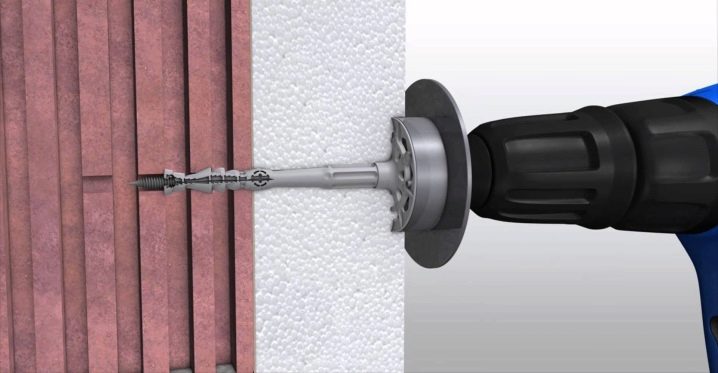

Depending on the material of the base of the walls, the holes for the dowels can be drilled with a drill or drilled with a perforator. The diameter and size of the drill are selected according to the diameter of the anchor zone and the length of the product. They work with a tool at a right angle, deepening the thickness of the insulation and the length of the anchor part into the wall. Dust must be removed from the drilled channel.

A dowel without a rod is mounted in the hole. The hat should be in the same plane with the heat insulator or slightly recessed. Then a screw or nail is installed. The rod must fully fit into the expansion part of the dowel.

See below for an overview of the Russian manufacturer's façade dowels.

The comment was sent successfully.