All about composite

The simplest analogs of a composite that come to mind for a beginner are confectionery waffle and wood plywood. In the first case, a creamy filling is located between the cakes with mesh projections. The second option is perpendicularly arranged layers of fiber, which are impregnated with an adhesive composition.

What it is?

Composite is a combination of layers of dissimilar and different types of materials that differ in a number of physical, technological and mechanical properties. One of the main requirements is neutrality, provided by a significant similarity in the chemical properties of the layers used. Technological and mechanical, as well as a number of physical properties of the resulting composite differ from the analogous initial parameters of each of the layers separately.

There are only two types of interlayers in a composite material: a matrix with cells and a filler. The simplest construction analogue of a composite is reinforced concrete, formed by a steel frame, the space inside which (and partly outside of it) is filled with concrete pouring, which hardened and gained strength within a month from the date of pouring the concrete solution.

The purpose of the composite material is to greatly improve the mechanical properties.

Types

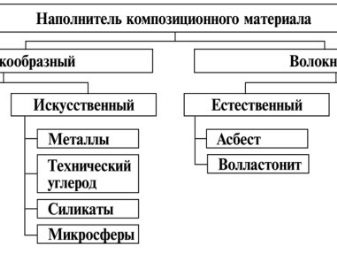

Structurally, composite materials are fibrous, dispersion-hardened, partially-hardened (not to be confused with partial hardening, mentioned in the sense of some improvement in the composition parameters) and nanometric.

Examples of composite materials.

- Stamp paper for money and documents containing synthetic hairs that increase tensile strength and abrasion. They are also one of the many indicators of a ticket counterfeit.

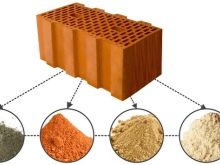

- Clay bricks with straw included. The adobe brick gains some resistance to cracking.

- Epoxy adhesive with metal or wood powder. The latter is introduced into the composition in order to save epoxy resin.

- Carbon that breaks in multidirectional impacts. It does not crack only when shocks and vibrations coincide in the vector of their impact with the direction in which the cyclist is moving. If you hit a carbon bike frame flat on any object, for example, a concrete post, then the carbon fiber will fly into fragments.

- Triplex - layers of glass on the front and rear visors of the car, held together by layers of celluloid. In the event of an accident, the scattering of a large number of wedge-shaped fragments is excluded, often resulting in the loss of vision of the driver who is involved in an accident.

Layers of tempered glass break into small cubic crumbs with blunt edges, while most of the fragments are kept by layers of plastic from flying in all directions.

So, armored glass for police and military vehicles is made of three or more layers of tempered glass - it can only be pierced with armor-piercing bullets or shells. Armored glass belongs to laminated composite materials. The variety of developments available today divides the composite material into dozens of types and varieties, each of which is in great demand in the market for construction and repair services.

So, there are mirror, filling, quartz and other composite materials designed for specific applications. The characteristics of each of these species differ from each other. For example, polymer-free nano- and microcomposites do not burn.They are charred only when heated to at least hundreds of degrees Celsius, which simplifies their use at temperatures unusual for room conditions.

Composite materials are manufactured according to the following scheme. First, the matrix component is applied to the reinforcing fibers, then the ribbons of the reinforcing ingredient and the matrix itself are formed using a compression mold. The resulting material is pressed out, sintered, and an additional coating is applied to the fibers. Further, the formed secondary material (the next stage) is sent for re-pressing, passes the stage of applying the matrix in the form of spraying with the help of plasma. The third pressing - squeezing - is the final stage. Thus, compression (pressing) is carried out at least three times.

Natural

Natural composite materials are lightweight, durable and state of the art. They are mainly used for aircraft, including airplanes and missiles. Uncomplicated composites are created by nature itself, for example, tree rings of wood, bark. Natural composite materials created by man are clay bricks, which contain sand, cement-sand blocks with the addition of sawdust, and others.

Classic

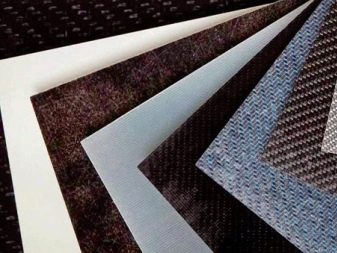

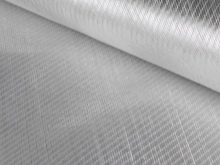

Fiberglass is recognized as one of the classic composite fibers. It is a plastic composite tape that sticks to all kinds of surfaces. This matrix holds the fiberglass strands in place. Thanks to the glass filaments pressed in this way, the strength of this material is ensured. Plastic is inherently soft and flexible, while glass is hard and brittle.

By combining these properties, it is possible to obtain a very flexible and at the same time solid material in which plastic and glass complement each other. The composite is used for the manufacture of bodywork for cars and motor boats. Glass composite does not rust or oxidize.

The same properties are inherent in carbon fiber (carbon): in it, carbon fibers are bonded together. A common example is carbon bike frames.

Modern

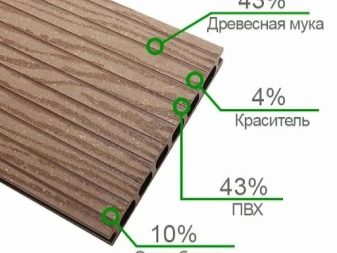

More modern building materials that appeared much later contain metal, ceramics and / or polymer as the main substance. The classification of these materials also takes into account non-metallic additives, such as wood chips or dust. Plastic-reinforced wood composite, or composite board (and sheet material made from the same ingredients), is used in furniture manufacturing and verandah or deck flooring.

Wood, crushed and mixed with a polymer melted to a soft state, is used as a hardened deck covering, on which you can walk and even move furniture: wood plastic board or sheet will not break or crack, being a solid material.

Polymer matrix

MDF - box or solid profile, which does not use synthetic resin or plastic, but exclusively resins of natural origin. Wood crushed into chips and dust is impregnated with this substance and then passes through the sintering and pressing stages in the oven. Common products made from MDF are high quality doors and laminate. During the sintering and hardening of the resin, they polymerize - a natural polymer is formed, in which wood dust is dissolved (and chips are distributed).

Metallic matrix

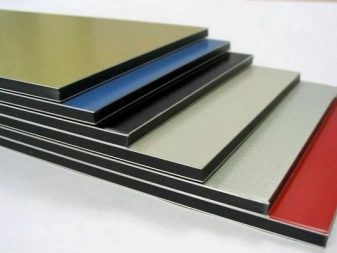

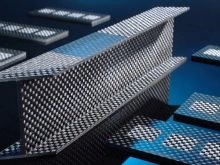

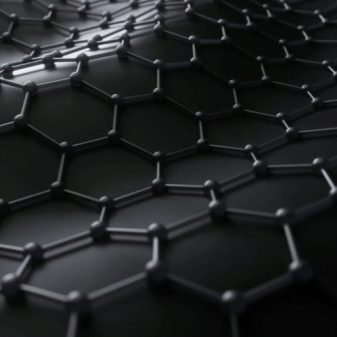

The simplest example is an aluminum or magnesium alloy reinforced with carbon fiber. But aluminum can be supplemented with silicon carbide, and the copper-nickel composition can be supplemented with graphene, a subtype of carbon fiber.Composite materials with a metal matrix are strong, have an acceptable rigidity for solving most problems, wear-resistant, resistant to oxidation, and have relative lightness in comparison with all-metal products.

They are expensive and difficult to process. For example, piston elements for diesel internal combustion engines are made of modern composites. Composite siding for the facade is made of sheet aluminum, between the layers of which plastic is poured. Staining helps to give a different color to such a finish.

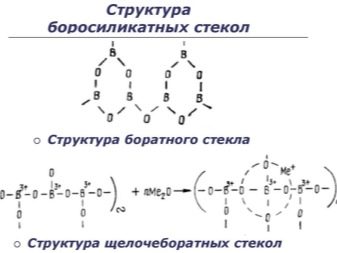

Ceramic matrix

Instead of metal, the main material in the ceramic composite, as you might guess, is ceramics. For example, boron-containing glass made on the basis of silicate inclusions is used as this element. It serves as a secondary matrix component and is reinforced with carbon fiber or ceramic inclusions, in the role of which silicon carbide is used. The ceramic composite allows, for example, to cope with the brittleness of solid ceramics, creating a characteristic reinforcement to overcome the phenomenon of kink cracking.

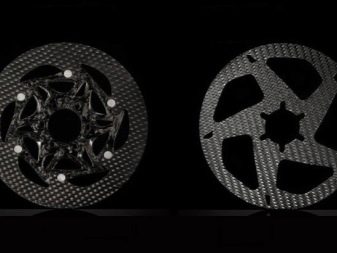

Carbon-carbide composite is one of the most demanded products on the market for composite materials., which makes it possible to obtain a composition that is ahead of carbon fiber and composite in terms of its strength characteristics and an indicator of the reliability of workpieces made from such a substance. Such a composite is used, for example, in the production of parts for an automotive braking and clutch system.

Due to the high-temperature environment in which they work, no plastic is used as a bonding component - otherwise, the material of, say, the same brake pad would quickly wear off.

Composite materials of the future

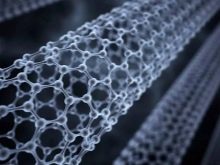

Today, the development of more modern materials does not stop, which would replace those that have already penetrated the market, which has tens of thousands of types of products made from them. So, the dimensions of reinforcing fibers in nanotechnology are 1000 times smaller than their longer predecessors. One of the materials of the future is carbon nanotubes, from which, for example, hockey sticks are made. In this example, the nanocarbon fiber is coated with a nickel-cobalt composite material. This club is nearly three times as strong and one-fifth more kink-free without cracking than a similar product made of steel alloy.

Dispersion-hardened composite materials are classified as nanomaterials in which the length of the main fibers is brought to a value of 100 nm. But in recent years, ten nanoparticles have shrunk in length to 10 nm - a similar approach is used, for example, in semiconductors and conductors that form a crystal of a microprocessor, microcontroller or microcircuits that form an electronic memory. Strictly specified standards are applied to composite beams and panels: for example, the stiffness (Young's modulus) must be at least 130 gigapascals, materials must resist fatigue wear, and be dimensionally stable. The goal is to solve all these problems at the same time. Disadvantages - high cost due to the increased knowledge-intensive load in the development, implementation and practical application of these materials.

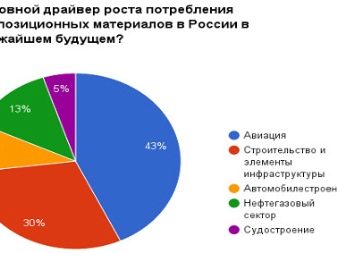

Composites market in Russia

The Russian market for the production of CM makes only 3% of export supplies of the global level. This is due to the lack of uniform regulatory documents that simplify the production of composite building materials, and until recently 90% of raw materials for production were imported.

So, the production of carbon fiber reinforced plastic in Russia has just begun to develop, while, for example, China is one of the leading manufacturers of composite. New materials, in the creation of which Russian scientists also participated, are based mainly on the use of nanoparticles.

Applications

Composite materials are used in aircraft construction for the production of certain engine components and aircraft load-bearing structures. Space industries use them for the production of load-bearing and cladding structures for rockets and satellites, which experience strong heating when entering orbit. The automotive industry uses composite materials for bodywork and bumpers. The mining industry uses CM as a material for drills. Civil engineering uses CM for the construction of elements for bridges and other high-rise structures.

The main prerequisite in different branches of mechanical engineering is the lightening of the dead weight of cars and special equipment, all kinds of vehicles: up to 70% of components are non-metallic material. A self-leveling floor (pouring floors), as well as pouring stairs, involves the use of a composite, in which, before it reacts with air, there is a semi-liquid, possibly syrupy substance. It is easy to apply such a composite to the concrete subfloor using epoxy glue in which the main filler is dissolved.

Payment

The calculation of the feasibility of using CM is based on the most important parameter - the effectiveness of the use of appropriate technologies. Metallic and non-metallic matrices in the manufacture of a more complex composite can be combined in a different sequence. As an example, a bicycle tire, in a treadmill of which several layers of reinforcing fiber are used: nylon, kevlar, thin steel wire and compound, which make it possible to increase the number of lines of protection. Thanks to these technologies, cyclists do not "grab" thorns and pieces of glass, wire, moving along the side of the road without asphalt, dirt roads and rocky roads.

Such a tire will go not one, but not less than twenty thousand kilometers before it is worn out so much that its punctures will nevertheless become a frequent occurrence. Calculation of the cost of one such tire, at which this price tag can increase 10 times or more, allows you to benefit from a small general reduction in price, without changing similar tires up to 10 times (this factor is regarded as a time spent on repair manipulations) - when passing all those the same 20,000 km on the same tires.

In this case, bicycle tires are a kind of multi-composite, where several enhancement layers (matrices) are used, and not one. The calculation of the production of a particular type of composite material is based on the form in which it is used. Reinforcing inclusions are used as threads, tapes, thin fabric, fibrous or rope component. The amount of hardener in the material by volume and by weight is 30-80%, depending on the purpose of a particular type of composite.

The number of threads in thread CMs is from three. In space exploration, this is of decisive importance: a kilogram of cargo launched into low-earth orbit is equal to a thousand dollars, and this is no less important for economic efficiency, which does not affect the progress of a single mission.

The comment was sent successfully.