Popular methods of installing a wet facade

The design of the facade of a building is just as important as its interior design. Modern manufacturers produce many practical materials that can be used for exterior decoration of houses of any size and layout.

What's behind the title?

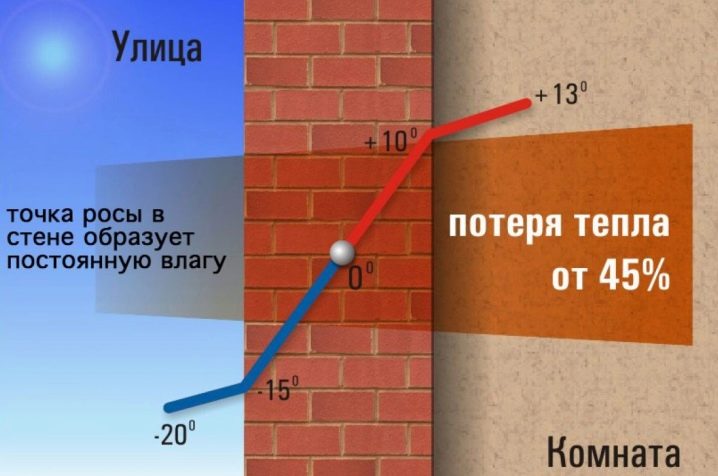

Not every homeowner knows exactly what constitutes a wet facade. Before proceeding to familiarize yourself with this finishing method, you should answer this question. The memorable name of the wet façade speaks for itself. In this case, it means the use of high-quality adhesive solutions in a liquid or semi-liquid state. Thanks to the introduction of this sophisticated technology, living quarters are reliably protected from the appearance of dew points - with a wet façade, they are led outside, and do not penetrate into the ceilings.

In addition, the definition of a wet facade includes three main methods of finishing private houses., in which the fasteners of heaters, reinforcing mesh and cladding are carried out using special adhesive mixtures. Even if there is a sharp temperature difference inside and outside the building, destructive condensation will not accumulate in houses with a wet facade. This technology saw the light back in the 60s - 70s of the last century, when the question arose about efficient energy saving of buildings. It is worth noting here that it is precisely high-quality external wall insulation in this case that is the optimal solution, since it makes it possible to move the dew point as far as possible from the interior spaces in the dwelling.

Technology features: pros and cons

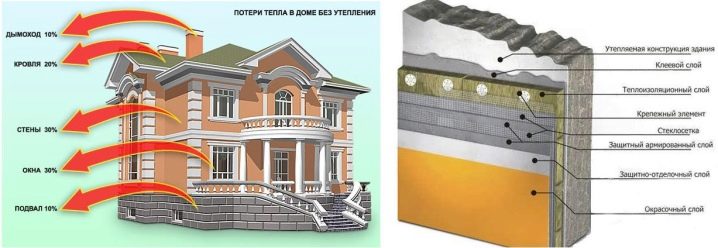

Currently, homeowners can choose the best insulation option for themselves - external or internal. However, the lion's share of consumers turn to reliable external systems in which the insulation is located outside. Today, many homeowners turn to this design of the facade of private houses, as it allows you to extend the life of building and cladding materials. In this case, as in many others, you first need to properly prepare the facade. After that, you can proceed directly to its insulation with suitable materials. The choice of heaters today is greater than ever, so you can choose the best option for any price.

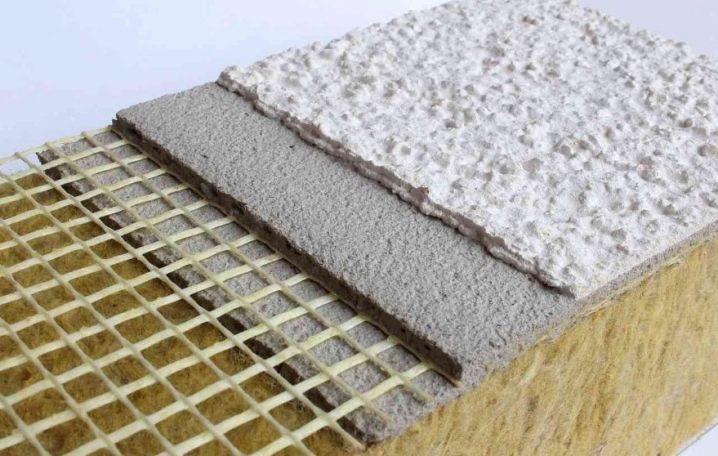

Only after this, the masters begin to apply a special adhesive to the insulating material. Following the technology, then a reinforcing mesh is applied to it, resistant to the effects of alkaline compounds. The final stages of all work are plastering the base, as well as applying a finishing layer of decorative trim. For a wet facade to be reliable and durable, it must be a multi-layer cake. This rule cannot be neglected, otherwise the cladding will be less durable and reliable, and it will be cold inside the dwelling.

These sophisticated systems boast many positive qualities for which they are chosen by many homeowners.

- One such system combines both decorative and heat-insulating functions, which is very convenient and saves time on additional work.

- If the walls of the house are too light or thin, then a wet facade is the ideal solution. With such a system, the house will become not only much more attractive, but also much warmer and more comfortable.

- Using a high-quality warm facade, you can significantly save on heating, since the housing does not need excessive heating.

- The good thing about a wet facade is that it can be used for any kind of substrate.

- With the help of such a system, additional sound insulation can be provided to the living space.

- Thanks to the wet facade, the service life of the house will increase significantly, as it will be reliably protected from negative external factors.

- With a similar design, the houses look much neater.

- Over the years, ugly salt stains do not appear on a wet facade, which is very difficult to get rid of.

- Overlappings with such a performance do not add in themselves, therefore, a reinforced foundation does not need to be made for them.

- According to experts, a wet facade is cheaper than analogs.

- In the presence of a wet facade, the interior of the dwelling will be protected not only from frost, but also from high temperatures. There will be no overheating and stuffiness in the rooms.

Today, such technologies are used by those who are used to taking care of their home and want it to retain its attractive appearance for as long as possible. However, do not think that a wet facade is a flawless solution, devoid of flaws.

It is worth paying attention to the disadvantages that are inherent in such a system.

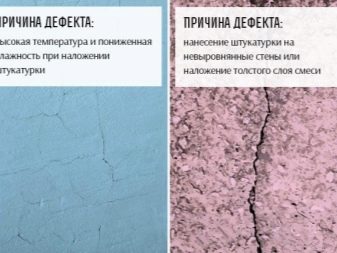

- Many homeowners are saddened by the fact that the installation of a wet facade can only be started at a temperature of +5 degrees Celsius. Otherwise, all materials may fail at the stage of application.

- In no case should the installation work be carried out if it is raining outside the window (even weak and fine). And during wet weather, it is better to postpone the installation of a wet facade "for later".

- When performing such a facade, it is necessary to ensure that all building and facing materials fit together.

- Direct sunlight hitting a wet facade can lead to excessive drying of the mortar on the ceilings, which can negatively affect the durability of the cladding and its durability and wear.

- Plastered substrates must be provided with high-quality wind protection. This is due to the fact that dust and dirt can adhere to the fresh coating during the settling process. At the same time, the type of finish will deteriorate greatly.

How serious the listed disadvantages are - everyone decides for himself. However, you will never encounter many of them if you adhere to the technology of arranging a wet facade. The quality of the purchased materials also plays an important role. Low-grade mortar and adhesive mixtures will not last very long, and their application can cause many difficulties.

Pie filling

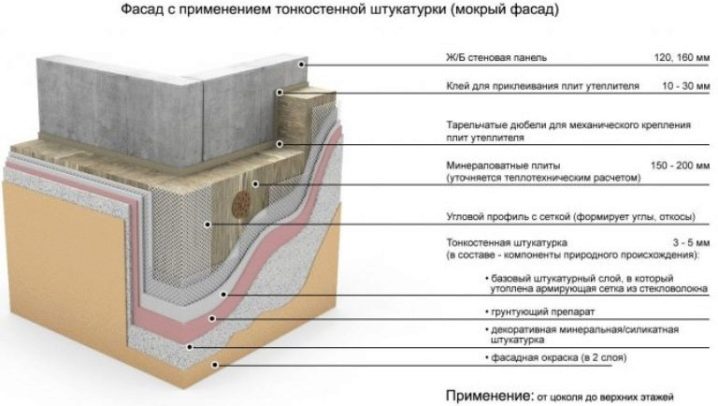

As mentioned above, a prerequisite for a high-quality wet facade is a competent “pie” arrangement. The latter includes several important layers, without which a reliable coating will not work. A special facade wall acts as a base in such a system. It can be any - brick, wood, monolithic, foam block or sheet. The main requirement that the base must meet is a perfectly flat surface. If we neglect this condition, air will constantly circulate between the floor surface and the insulating materials, due to which the insulation in the room will not reach the desired level.

The next important layer of the "pie" is the heat-insulating layer. Experts recommend buying nets that are not afraid of contact with alkalis. After the heat is followed by a reinforced layer. As a rule, it contains mineral glue and a reinforcing mesh. Further, you will need a layer of high-quality facade paint or decorative plaster. It is also allowed to purchase special facade slabs that are lightweight for finishing.

Among other things, it should be borne in mind that the entire "pie" of the wet facade must be watertight. That is why all materials must be selected in such a way that each new layer in the direction from the inside out is more vapor-tight than the previous one. Only if this requirement is met, the dwelling will “breathe”. And also it should be borne in mind that the thermal circuit of the "pie" should remain uninterrupted. There should be no cracks, gaps or cracks in it.

Types: recommendations for use

A multi-layer system called a wet facade is very popular today. Many homeowners choose it, however, not all of them know that there are several varieties of such a facade design. To begin with, it is worth considering in detail what subspecies wet facades are divided into according to the materials used.

- Organic. In such systems, as a rule, cheap foam plastic acts as a heater. As for the reinforcement, it is performed using a special reinforcing mass of organic origin. The final finishing coat in this case is a silicone plaster mix, although organic plaster can be used instead.

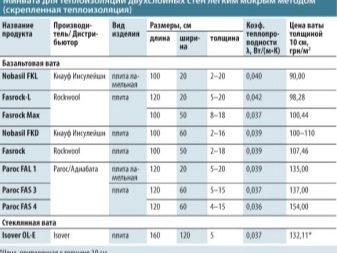

- Mineral. If you decide to turn to a mineral wet facade, then you should purchase high quality mineral wool for insulation. Reinforcement in such a system occurs with the help of a special reinforcing solution of mineral origin. For the final decorative coating, the same material is suitable as for organic options.

- Combined. With such a system, inexpensive foam is also used for insulation. Mineral raw materials are used for further finishing.

Modern wet facades also differ in the method of fixing.

- With a heavy version, the insulation does not need to be installed directly on the floor. Instead, slabs of thermal insulation material are slid onto dowels fitted with small hooks. These fasteners are pre-inserted into the walls. In this case, a reliable mesh made of metal is applied to the insulation. At the same time, this element is attached to special pressure plates. After that, you can proceed to plastering the bases and finishing them with a finishing layer of material. It is quite possible to cope with such work with your own hands.

- Light facades are much more common than heavy ones. With this type of finish, the insulation is attached directly to the walls. For this, it is permissible to use a suitable adhesive together with plastic dowels.

The choice of insulation

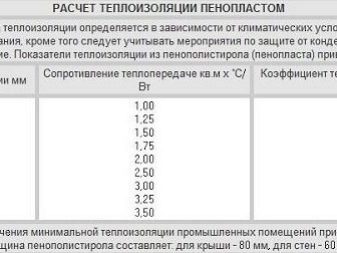

One of the main roles in a wet facade is played by a properly selected insulation. Today, for this, as a rule, they choose either foam sheets (their thickness should be from 5 to 10 cm), or high-density mineral wool (it is better to take basalt products).

The choice of insulating material for a wet facade should be very careful and balanced.

At the same time, experts recommend paying attention to the following important parameters.

- Price. As for this criterion, then foam plastic undoubtedly outperforms mineral wool. This material has been used for a very long time and is inexpensive, so many consumers choose it, despite its fragility.

- Water vapor permeability properties. Such qualities are inherent in the popular but expensive mineral wool. According to professionals, the house "breathes" with such a heater, therefore it is more comfortable to be in it. In addition, "breathing" dwellings are not susceptible to the formation of mold and mildew. Polyfoam does not differ in special vapor permeability, being inferior in this case to mineral wool.

- The complexity of installation work. If we compare foam and mineral wool in terms of the complexity of the installation, then we can immediately say that the first of them is simpler and more malleable. This is due to the rigid foam structure.

- Fire safety. Fire safety characteristics are also very important for insulation. So, foam plates are combustible, so they must be treated with fire retardants. Basalt wool does not burn. It can withstand temperatures up to +1000 degrees.

And also you need to pay attention to the thickness of the purchased insulation. Today, in stores of building and finishing materials, you can find many insulation materials with various dimensional parameters. The thickness of the slabs is different and can be from 25 to 200 mm. As a rule, the pitch in this case is 10 mm.

It should be borne in mind that too thin sheets of insulation may be ineffective. But you do not need to rush to extremes, because too thick materials are also not recommended to be used, since they will only lead to unnecessary spending, and in a home with excessive insulation it will not be very comfortable. Experts strongly recommend purchasing high-quality insulation materials from well-known manufacturers for the facades of buildings. Excessive savings can lead to the purchase of a low-quality product that will not perform its basic functions and will require replacement, and this is an additional expense.

Materials and tools

An ordinary home craftsman can also build a high-quality wet facade. However, for this you need to stock up not only with patience, but also with all the necessary tools and consumables. All materials and tools must be of unsurpassed quality. It will be much easier to work with such components, and the result will definitely not disappoint.

It is worth considering all the positions that may come in handy for such work.

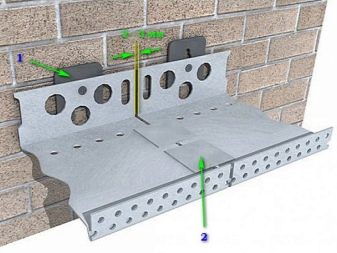

- You will need a starter or base profile. It is necessary to ensure that the parameter of its width corresponds to the thickness of the insulation. The quality of the profile here must correspond to the perimeter of the ceilings to be finished.

- You should purchase reliable connection parts for the base / plinth profile. Thanks to these components, it is possible to achieve perfectly correct joining of all profiles in a single plane. In addition, these components allow you to form the correct joint (temperature gap) between the profiles.

- Fasteners for frame profiles. It is worth making sure that the expansion dowel-nails have a length of at least 40 mm if partitions are finished from solid brick or concrete. For ceilings consisting of hollow bricks, it is recommended to choose fasteners 60 mm, for aerated concrete and gas silicate - 100 mm. It is easy to count the points of fasteners. If the insulation layer is 80 mm or more, then the step will be 300 mm, and if the thickness is less than 80 mm, the installation can be done in 500 mm steps. A plastic spacer is required for each attachment point. This part is useful for the most accurate and correct alignment of the profiles.

- It is necessary to purchase a quality primer to prepare the slabs for gluing the slabs. In this case, it is recommended to buy deep penetration soil for brick, plaster or gas silicate bases. Its average consumption is 300 ml per 1 m². For concrete bases, it is better to buy concrete-contact soil. The average consumption of such a solution, as a rule, is 400 ml per 1 m².

- It is necessary to purchase a high-quality adhesive for fixing the insulation boards. Select only adhesives that are specifically designed for such tasks.

- It is worth buying high-quality insulation boards with a pre-calculated thickness. Their average consumption, taking into account cutting and possible waste, takes from 1.05 per 1 m².

- You will also need a dowel-fungus. They are needed to mechanically strengthen the insulation material. In total, the length of the dowel should correspond to the thickness of the insulation, as well as the length of the spacer.

- You will need to stock up on materials for applying the base reinforcing layer that goes along the insulation plates.For this, a specialized plaster mixture or a reliable adhesive composition is most often purchased, which is also used for installing warm plates.

- You need to buy a reinforcing mesh. It is recommended to purchase wear-resistant and durable products from materials that are not afraid of alkali.

- It is imperative to stock up on water-dispersive soil, decorative plaster and paint specifically for outdoor use.

Preparatory work

When all the necessary components have already been prepared, you should proceed to the next important step - this is the preparation of the foundations for the future installation of a wet facade.

It is worth disassembling this process using the example of fixing the insulation to a suitable adhesive composition.

- Insulation plates can be attached with glue only if the base is thoroughly cleaned of all excess. For example, if the old paint and varnish coating is present on the facade, then it will need to be removed right down to the base itself or a layer of plaster.

- It is allowed to leave the old plaster only if it is still in perfect condition. To make sure of this, you need to carefully check the base with a light tap. If unstable areas are found, they should be quickly cleaned up.

- If there is mold or mildew on the walls, then they cannot be used for arranging a wet facade. Such defects must be removed from the walls.

- After removing the fungal deposits of the overlap, it is necessary to coat it with a special "healing" agent. It is allowed to start other work only when the antiseptic on the bases is completely dry.

- It should be noted that the walls must be flat. Any irregularities, cracks, cracks and potholes must be repaired. It is worth sealing them up with soil, sanding.

- It is necessary to inspect the plane of the walls both horizontally and vertically. If deviations exceeding 20 mm were noticed, then it will not be possible to level them a little later with plaster, so problems need to be solved as soon as possible.

- Install metal components on the walls in advance, which are used for mounting antennas, gutters, lighting fixtures and other similar things.

- When the repair and plastered layer on the floors is completely dry, the surface must be primed. Primer can be applied with a roller or brush. You must try not to lose sight of a single site on the base.

Installation and plastering

If the base is prepared correctly, then you can proceed to the installation of the starting basement profiles and the further installation of the insulating material.

It is worth considering step-by-step instructions for carrying out these works.

- The basement profile must be placed strictly horizontally. It is on it that the first insulation plate will be installed. The evenness of the location of this part should be monitored using a level.

- You should never overlap profiles. It would be more correct to mount these parts exclusively end-to-end, maintaining an interval of 2-3 mm.

- At the outer and inner corners, the profiles must be fastened while maintaining a gap. For this purpose, these parts are cut at an angle of 45 degrees.

- If the density of the insulation exceeds 80 cm, then you should take care of temporary stops for mounting the starting profile. These parts should not bend. After installing the insulation, the supports are simply removed.

- When all the supports are ready, you should proceed to the preparation of the solution. You should follow the instructions on the package.

- Gradually add a dry solution to the required amount of water. To bring all the components to a liquid state, you need to use a drill with a mixer attachment.

- Stir the composition until a single mass without lumps is formed. This usually takes 5 minutes. Next, you need to make a short pause for 6–8 minutes and mix the solution again.

It is permissible to lay the glue on the insulation material in the following ways:

- in strips of 100 mm along the perimeter, leaving 20-30 cm from the edge;

- small slides with a diameter of about 200 mm, while the height of the applied solution can be 10 or 20 mm.

If the wall to be insulated is fairly flat, then the glue can be applied to its entire surface using a notched trowel. It is recommended to apply the glue as follows:

- a small amount of the mixture must be rubbed into the coating of the insulation plate, with little effort;

- transfer the required amount of adhesive.

Further, the slab, smeared with glue, leans into place and presses firmly against it. It is necessary to distribute the glue, slightly moving the part to the sides, up and down. Any excess glue that will enter the edges should be removed as soon as possible. The next slab of insulation should be placed as close as possible to the previous one, leaving no gaps. If it does not work without them, then they can be closed with mineral wool wedges. As a rule, the installation of insulation begins from one corner, moving further in rows.

In this case, the following rules must be observed:

- the initial row must be installed in such a way that it rests against the first profile along the side (limiter);

- the plates must be laid with a shift of the vertical joints by at least 200 mm;

- at the corners, use the "gear lock" technique;

- parts of slabs close to corners, partitions or slopes should not be more than 200 mm wide;

- as soon as possible, you need to dock the insulation layer with the ceilings and slopes.

When completing the installation of the insulation, you need to make sure that there are no gaps and gaps anywhere. All defects must be eliminated with the remnants of mineral wool. After laying the insulation, a reinforcing mesh should be installed. It is needed for the finishing layer.

Finishing

When the reinforcing layer is completely dry (it takes from 3 to 7 days), you can proceed directly to the finishing of the bases. Apply a thin layer of the plaster mixture evenly, using a scraper at an angle. The resulting surface will be the ideal base for processing with reliable facade paint or other selected material. This procedure is the last step in warming the outside of the house.

Tips & Tricks

When installing a wet facade, you should follow the advice from specialists.

- For work on the facade, you can use only those materials that are not afraid of temperature changes, otherwise, as a result, you can get cracked plaster.

- It is worth running your hand over the surface of the base. If there are traces of chalk on it, and something is crumbling from the wall, then the floors should be cleaned as carefully as possible.

- The plinth profile after installation must be in one line. There should be no gaps or crevices in the connection areas.

- Experts strongly advise against choosing fiberglass plates for home insulation. Such materials cannot boast of sufficient strength. Moreover, they are afraid of alkalis, without which plaster and adhesive mixtures cannot do.

- The heat insulator should not be pressed against the base again. It is also not recommended to move it after a few minutes. If the insulation is not glued properly, then you should remove the glue solution, and then apply it again to the plate and press the part to the surface.

- In the process of insulating slopes, it is necessary to ensure that the insulating material extends beyond their limits by about 10 mm. With this option, it will be much easier to dock the main facade insulation.

- During installation, the dowel is considered to be correctly installed if its head is located in the same plane with the heat-insulating layer.

- The reinforced mesh cannot be laid by installing it on a heater that was not previously coated with glue, since if the reinforcing layer is rather thin, then cracks will appear at its joints.

- If you decide to do all the work yourself, then you should stock up on branded materials and mixtures from well-known manufacturers, despite their cost. It is advisable to purchase products that have good consumer reviews.

- Facade work should be carried out in late winter or early autumn. It is advisable to familiarize yourself with the weather forecast before proceeding to the design of the facade.

Beautiful examples

A wet facade with a rough peach-colored finish looks spectacular on almost any house, from small to large and multi-storey. You can dilute the pastel paint with light side inserts and a dark roof.

Light coffee facades with white window frames look very delicate. In tandem with ceilings of a similar shade, a dark chocolate roof, as well as a fence made of wood and brick, will look harmonious.

A wet facade, finished with snow-white or cream paint, will look spectacular if supplemented with inserts under a gray wild stone. Such a building can be decorated with rocky paths and wrought-iron fences around the site or balcony.

The original wet façade with coffee borders can be complemented by stonework at the bottom. On such a house, a burgundy-colored roof will organically look, which will effectively dilute the pastel palettes.

See the next video for more details.

The comment was sent successfully.