What is asbestos cement and where is it used?

Many people will be interested to know what is asbestos cement, what are the features of couplings 300 and 400, strips of asbestos cement, as well as other products from it. Asbestos-cement foundations and boards, roofing and pillars are often made, their sizes can vary greatly. Finally, it is worth considering the nuances of technology and field of application.

Advantages and disadvantages

Asbestos cement can hardly be called a very new material - on the contrary, it has been used for quite some time. And yet, many consumers do not yet know its properties well enough. Meanwhile, a classic example of such a product is just an ordinary slate. This is a completely heat-resistant material, and the refractoriness of certain types of asbestos cement is sufficient for metallurgical production. In terms of vapor permeability and thermal properties, asbestos-cement structures are also very good.

No wonder they are used in the design of walls in summer cottages and cottages. Effective micro-ventilation and removal of excess moisture, which so often causes inconvenience in rooms, is fully ensured. Low electrical conductivity pleases both manufacturers of electric motors and those who design various kinds of network infrastructure in homes. In the open air, another property is valuable - frost resistance, which is quite acceptable even for the conditions of the Siberian and Ural climates.

There is only one obvious drawback for asbestos cement: its high density, which leads to both solid weight and low strength, which does not allow the use of this material in loaded structures and objects.

How is it different from other materials?

It is most convenient to illustrate this difference with the example of the discrepancies between asbestos cement and chrysotile cement similar to it externally, and in practical terms. Asbestos can be potentially more dangerous during installation and various work with it. But this problem is successfully solved by using personal protective equipment. In terms of practical use, there is no difference, and already mounted structures made of both materials are not dangerous. These two substances:

-

not subject to corrosion;

-

tolerate stray currents;

-

usually have smooth surfaces;

-

safe in terms of fire;

-

tolerate contact with alkali;

-

serve for a very long time.

In comparison with other materials similar in purpose, asbestos cement (at least as a roofing material):

-

is not that expensive;

-

chemically resistant;

-

allows you to simplify the installation process;

-

sold in a wide range;

-

absorbs noise;

-

can be overgrown with moss and other biological agents;

-

more fragile;

-

relatively heavy.

Manufacturing technology

Asbestos cement is obtained, as its name implies, by combining asbestos and cement. Natural fibers appear in the earth's crust when mineral waters are exposed to a certain type of igneous rock. No other mineral is able to separate as actively into thin and soft filaments. Asbestos-cement products are mainly obtained by pouring a prepared mass with a normalized viscosity level onto a metal mesh. The next stages of production are water removal and molding in a certain way.

Asbestos usually arrives at factories in the form of briquettes. After unloading from the transport, it is fed along a conveyor to disintegrating disintegrators. From there, in a crushed form, the substance is sent to be stored until there is a need for a specific portion. Special "silos" free from asbestos mass using disc feeders and other necessary infrastructure. The next step in technology is fluffing; mainly due to its greater efficiency, it is carried out using the wet method.

The actual preparation of asbestos cement and products from it can be cyclical or continuous. In a cyclical scheme, the incoming mass is kneaded and moistened in the "runner" type installations. Then comes the turn of the procedure for fluffing and mixing the fibers with cement on a special gollender. In total, these actions take from 22 to 27 minutes. If the asbestos is of high quality, it is sometimes prepared in two or even three stages.

Forming and curing are of great practical importance. Their direct execution depends on what specific product is being made. Sheet products are prepared on special pads or substrates. But sometimes they can be obtained without such substrates, running on a special conveyor.

The choice between these options is due to purely engineering considerations, and it should be made by specialists.

What are they making?

Many useful things can be made from asbestos cement.

Cardboard

This type of asbestos-cement products is used mainly for thermal insulation work. Its use really allows you to reduce unproductive heat losses and save on production, heating of residential and public buildings. Compared with many other heaters, cardboard mixed with asbestos cement has a zero fire hazard. In addition, it is quite durable, not afraid of alkalis and non-toxic material, and it is not surprising that it is bought quite often.

Asbestos board is also appreciated for its resistance to electric current and minimal transmission of extraneous noise. Some grades of this material are used to seal connectors on industrial equipment. Most often, asbestos-board sheets are placed on a flat surface, having previously moistened them. After moistening, the material dries quickly.

This circumstance makes it possible to reduce downtime during construction, installation and repair.

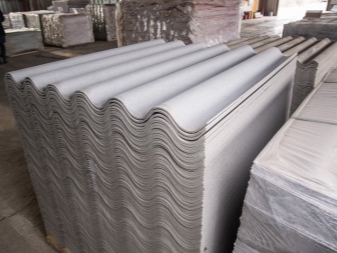

Slate

This is a well-known and familiar to many method of roofing. Such a solution was first demonstrated at the beginning of the twentieth century. It is customary to divide slate into corrugated and flat sheets of various sizes. In the first group, there is additionally a division by the number of "waves". This roofing material:

-

non-flammable;

-

easily processed with various tools;

-

relatively affordable;

-

does not make a strong noise when hit by rain and even hail;

-

can split into small fragments under the influence of fire, thereby even contributing to the spread of fires;

-

tends to deform with constant walking.

Cords

This option is prized for its exceptional thermal performance. In standard mode, it can withstand up to 300 degrees. And for a short time it can even withstand heating up to 400 degrees. The cord is an excellent heat-resistant and heat-insulating (as appropriate) construction. Supplied in bays, which are measured in kilograms; diameters can range from 0.25 to 0.75 mm.

A quality cord is always elastic. It should not have broken sections and even separate threads. The largest mass of the bay reaches 60 kg. Storage of such products in a humid environment is not allowed.

It is quite possible to insulate with a cord and hard-to-reach areas.

Fabrics

Similar matter can be done using:

-

rep;

-

simple linen;

-

twill weave.

The strips of fabric are wound into rolls. There are both standard and oversized rolls. Their greatest weight is 80 kg. There are asbestos fabrics of white, yellow-green or yellow-brown color.

Additional staining is carried out at the request of customers.

Padding

They can be obtained both by diagonal braiding and by braiding the asbestos core. Modern manufacturers offer both round and square gaskets. The choice between these options is due to a purely technological feasibility. Additional impregnations are often used (of course, safe for health).

The prospects for such packings are very great.

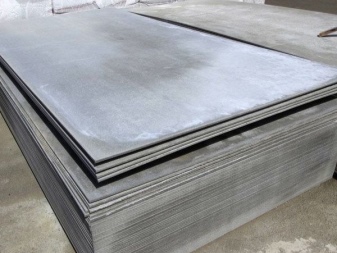

Sheet material

Such structures are obtained by combining asbestos with:

-

Portland cement;

-

quartz sand;

-

water.

Sheet asbestos cement is affordable and has impressive practical characteristics. It is believed that this is an inexpensive and aesthetic material at the same time. The selection of models that match the look of the house by design is not difficult for any trained person. Flat sheets can be compressed or unpressed. Important: it is almost impossible to distinguish between these two types by their external properties.

Couplings for pipes with a cross section of 100, 150, 300, 400 mm can also be made of asbestos cement. But it is curious that boards are also made on the basis of this material. Such elements are very widespread in modern construction. They are usually taken when you need to prepare the formwork for the foundation. ACEID products have proven themselves well as protection against ionizing radiation and can be painted in arbitrarily chosen shades.

When used indoors, fire is excluded. In the production process, modern technological solutions and high-quality raw materials are used. If you need to equip a fence, then usually asbestos-cement pillars are taken. They can have different diameters, and at the same time they are clearly better than traditional wood resistant to moisture, to the effects of harmful insects of all kinds. But one must understand that pipes, despite their strength, are relatively fragile, and their appearance does not always suit people.

Rings are mainly used when you need to equip a well. They are durable and do not require pouring, as they are initially sold ready-made. As for crumb, only material in which the particle size does not exceed 1.35 mm can be called so. These requirements must meet 95% or more of the total mass of the shipped goods. Depending on the size and technical characteristics, a division into grades can be introduced.

Applications

Asbestos cement is most often used when working on the roof. This is, again, about the well-known slate. Traditionally, nails are used to fasten it. But in recent years, special construction screws have become more and more widespread. Asbestos-cement pipe foundations are also increasingly used.

In addition to the described areas of use, this material is still needed:

-

for obtaining various finishing and protective boards;

-

in the production of sewer pipes;

-

for the manufacture of connecting links of pipelines;

-

upon receipt of ventilation, plumbing and electrical insulating boxes;

-

in the manufacture of workwear with maximum heat resistance;

-

in the production of electrical boards and arc extinguishing chambers;

-

in induction furnaces;

-

in spark extinguishing partitions;

-

as a fence for an electric arc furnace;

-

in gas pipelines;

-

in the arrangement of various wells.

The comment was sent successfully.