Imitation of timber: features of materials for exterior decoration of the house

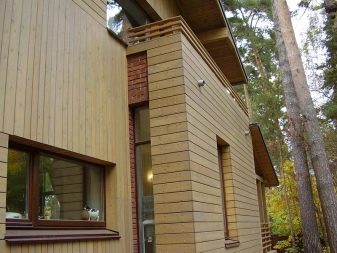

A house made of glued or profiled timber looks stylish and expensive, but not everyone can afford it. Therefore, an alternative has appeared - you can sheathe the room with an imitation of a bar. At the same time, visually, the house will be very similar to a log house, and the financial costs will be much less.

What it is?

Timber imitation is also called false beam. It is a material that can be used for cladding both outdoors and indoors.

Today there is an artificial imitation of a barmade from wood waste with the addition of plastic, as well as a solid wood option that is especially popular with consumers. It is worth considering in more detail.

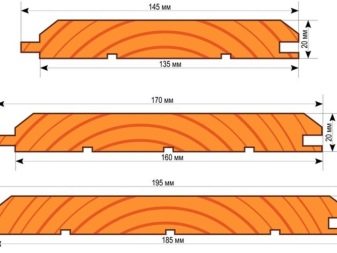

It is a planed board, processed from 4 sides, and made in the form of a processed wooden bar. The thickness of such material is up to 35 millimeters, and the width can reach 260 millimeters. The material of manufacture is coniferous and deciduous wood. The profile in this case is the trapezoid, and due to this, the smoothness and evenness of the base is achieved.

For the best fit, the edges are processed in a special way, this allows you to reliably protect the insulation from the effects of negative climatic conditions and humidity. The fact of what material a product is made of determines its density and characteristics.

Advantages and disadvantages

The modern market offers a wide selection of imitation timber. The consumer can choose the appropriate material based on the price of the product, its appearance and performance. False beams are very popular when decorating the facades of private frame houses and cottages. This is due to its positive properties.

First of all, the material is natural and environmentally friendly. It is non-toxic and does not have an unpleasant odor during use. The products are absolutely safe for humans and can be used when working with any premises.

The panels do not cause problems during installation, it is quite possible to do it yourself, having an idea of \ u200b \ u200bthe finishing work. In addition, imitation of a bar looks more neat in comparison even with natural wood, while having a much lower cost.

If the installation was done competently and with high quality, the products will last a long time without creating problems for the owners. Imitation timber has a protective function. It is resistant to mechanical stress and aggressive climatic conditions. It should be noted the wide range of colors of materials, which allows the consumer to choose the desired shade, thanks to which the houses look expensive, profitable and stylish.

At the same time, one cannot but mention the negative aspects. One of them is the high fire hazard of materials. To extend the service life of products, it is recommended to treat them with special solutions that have antiseptic properties and also reduce flammability. They will also protect the façade from drying out and cracking.

In order for the imitation of a bar to constantly look good, and also not to lose its properties, it is necessary to periodically cover it with paints and varnishes, which carries extra financial costs. And you also need to take into account that the components for the panels are not cheap, and their use is mandatory if the work is carried out correctly.

For those homeowners who do not have the desire to clad the facade with wooden panels, manufacturers offer metal siding under the timber. Its service life, according to reviews, is up to 50 years, and visually the structure looks like a log.

Views

For the exterior decoration of the building facades, materials of different types can be used. They all differ in external parameters, as well as in physical properties.

First of all, the false beam is divided into types according to the material of manufacture. There are products made of pine, cedar, larch and other types of wood. In addition, the panel sizes can be varied.

The price category is influenced by the type of wood from which the panels are made. They are divided into varieties of category A, AB, B and C. This information must be reflected in the certification. The performance characteristics depend on the variety.

The price of grade A is higher than the others, but its quality is better. The material of manufacture is pine. To finish the living space from the outside, it is recommended to use classes A and AB. Grade C is more suitable for facing outbuildings.

But also when choosing the type of finish, you need to take into account the operating conditions. In rooms with high humidity, it is better to use linden and larch.

The imitation of the timber is divided according to the geometry of the profile. Here you can distinguish a block house and lining.

The dimensions of the imitation of the timber are different, they must be selected based on the preferences of the consumer. Width ranges from 140 to 190 millimeters, length - up to 6000 millimeters. The thickness is selected depending on the type of planned work and conditions of use, it can be from 16 to 35 millimeters.

Features of choice

There are a wide variety of options for siding imitating timber on the market. The price of materials can be significantly different. To save money, experts recommend buying panels directly from the manufacturer in order to avoid markups from construction stores. But first of all, you need to choose high quality material. For this, individual points should be taken into account.

The humidity indicator should not be higher than 15 percent, otherwise it may threaten the façade warping during operation. The groove in the panel serves to ventilate the façade and helps to prolong the appearance of the panels.

The width of the siding is also important to the appearance of the building. To make it look like a natural timber, the width should be about 100 millimeters. Very narrow panels look cheap, and wide ones look sloppy. In addition, you need to pay attention to the quality of the lock connection. Its evenness and smoothness are important, as well as the absence of defects and damage.

And it is also necessary to choose the right decorative elements. It is they that increase the wear resistance of the surface, and are also responsible for the attractiveness of its appearance. Therefore, you need to choose quality products.

Before performing work, it is necessary to calculate the material and its components. To do this, you need to measure the walls, window and door openings. The area of the openings will not be covered with a false beam, so it must be subtracted from the total so as not to purchase unnecessary finishing materials.

How to carry out the work?

High-quality panels do not cause problems during installation, you can do it yourself. However, it is necessary to have an idea in what sequence and how exactly the work is carried out.

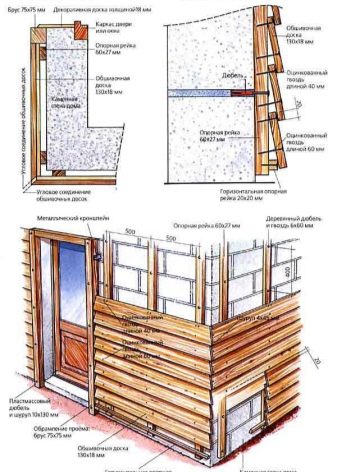

The first step is to prepare the surface. The walls are thoroughly cleaned of dirt. It is recommended to treat them with an antiseptic to exclude the appearance of mold and mildew.

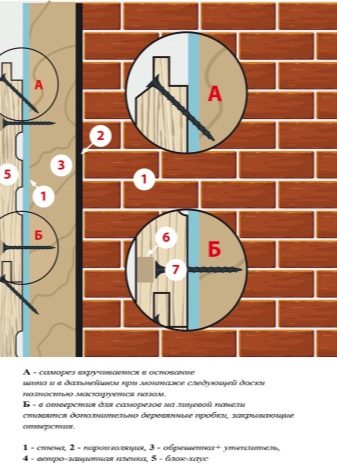

After that, the installation of the lathing is carried out. It is important to install it vertically on the base. If the surface is wooden, fixing is done with self-tapping screws; for a surface made of bricks or cinder blocks, dowels are used, driven into prepared holes.

An important step is to carry out high-quality vapor barrier and thermal insulation of the room. The insulation is laid on top of the vapor barrier film and closed again with it. The joints must be glued.

Next, panels and decorative elements are attached directly. After that, the facade should be fixed with screws or nails. In the absence of a topcoat, the final stage is surface treatment with an antiseptic and paints and varnishes.

Important nuances

False beam goes on sale in sealed packages. After purchase and before work, these packaging must be opened, and the products must be laid out in the air, avoiding exposure to open sunlight and precipitation. The panels must be left in this way for two days. This is done because after opening the sealed package, the wood will absorb moisture, and, as a result, it may increase in size, which will lead to a distortion of the building facade.

The panels are fixed from bottom to top, the groove must be located at the bottom. This will help prevent moisture and dirt from entering. The first panel is installed using a level. It depends on its correct installation how smooth the entire surface will be. The fasteners are screwed in at a 45 degree angle.

Work must be carried out exclusively in dry weather and at a temperature of at least -15 degrees. Coloring is done only in warm and dry weather.

When choosing a color, it is recommended to take into account the location of the building. It is better to make the walls on the south side light, as the dark ones will fade in the sun. And the northern ones, on the contrary, are better to be made dark. This will provide them with better heating and warmth in the room.

Care

For a longer service life of facades faced with imitation timber, it is necessary to properly care for the material. First of all, we must not forget about the periodic coating of the panels with varnish. And you should also regularly check the surface to exclude the appearance of defects, fungus and decay.

Experts note that in the case of competent installation of the coating and proper care for it, the imitation of the timber will last for many years without losing its visual appeal and its positive properties.

For information on how to properly mount an imitation of a bar, see the next video.

The comment was sent successfully.