Crushed stone fraction for concrete

Any concrete solution is required to include auxiliary components, on which the finishing strength and all the necessary properties directly depend. To make a high-quality composition, you need to use several components - cement, water and high-quality filler. In the overwhelming majority of cases, crushed stone (in a simple way, crushed stone) is used as a filler for concrete, which has excellent performance that is optimal for construction. To make a high-quality composition, you should find out all the key properties of crushed stone, as well as its varieties that can be used.

Primary requirements

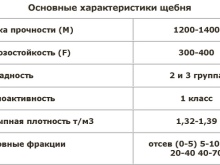

The technical indicators of ready mixes directly depend on the basic requirements for crushed stone.

-

Average value of grain density crushed stone should be equal to 1.4-3 grams per 1 cm3.

-

The strength of the original rock when squeezed, it is set by the ultimate resistance during clamping and grinding of the material produced.

-

Flakiness. This is a parameter that characterizes the plane of the gravel. In construction, plate-like forms of material devoid of smoothness are practiced. Based on this, there are several types of stone categories. The cubic shape is optimal, since it achieves an excellent compaction.

-

Fraction (grain size) of crushed stone for concrete. This parameter sets the dimensions of the applied material.

-

Frost resistance. This property will show in what temperature limits the crushed stone can be practiced. The letter F is used for marking, as well as a number indicating the cycles that the crushed stone can withstand when freezing and thawing. Crushed stone with the F300 marking is endowed with the optimal property. This indicator, in particular, must be adhered to in the conditions of domestic construction, where the temperature of the atmosphere in the summer and winter periods varies considerably.

-

Radioactivity. This indicator indicates the natural radioactive background of the material. When grade 1 is indicated on the package, then it can be practiced in a variety of jobs. Class 2 is used for paving.

As already mentioned, the fraction affects the quality of concrete no less than the type of crushed stone. Its selection also depends on the proposed work. For concrete mortar, crushed stone of fraction 5-70 millimeters is used. A finer distinction is formed by subgroups of 5-10 millimeters, 10-20 millimeters, 20-40 millimeters and 40-70 millimeters. For concreting, it is preferable to use larger fractions of gravel and crushed stone, since in this case the filler used will be endowed with a lower specific density and exert minimal pressure on the cement solution, which guarantees the necessary mobility of the concrete mixture.

There are standards according to which the filler of increased size should be equal to from 1 to 20% of the weight, and of reduced size - no more than 20% of the mixture.

According to SNiP 3.03.01-87, the concrete solution must contain crushed stone in its structure at least 2 fractions with a limiting value of elements up to 40 millimeters and at least 3 fractions, when the largest components are 40-70 millimeters. The largest size of crushed stone should be within less than one third of the smallest distance between the longitudinal reinforcement bars. Equally, it should not exceed 1/3 of the smallest size of a certain building part, for example, its tape width.

The service life and reliability of concrete structures primarily depends not only on the extent to which high-quality materials are used, but also on how the mixture is correctly composed.

In order to obtain high quality concrete, all the details of its manufacture should be taken into account.

What kind of crushed stone is needed for different types of concrete?

Different types of concrete involve the use of different types of crushed stone.

M-100 concrete

It has not very high strength, it is not intended for critical structural elements. It is practiced for pouring the floor in basements, for laying the foundation for covering roads, sidewalks, foundations. To prepare the mixture, secondary or limestone crushed stone with a size of 5-20 millimeters can be used.

Concrete M-150

Belongs to concretes with an average strength value. It is practiced in individual construction for some minor works, including preparation of the foundations of sites and paths, screed construction, concreting of supports and pillars, construction of monolithic low-load foundations. The aggregate can be a gravel mixture or crushed limestone of 5-20 millimeters.

M-200 concrete

Heavy concrete, has an average strength value, is practiced for pouring the foundation of low-rise buildings, alleys, platforms, blind areas, flights of stairs, and so on. The filler is granite or gravel crushed stone. For this mixture, the grain size of crushed stone can be in the range from 5 to 40 millimeters.

M-250 concrete

Quite strong concrete with a bulk density of 1800-2500 kg / m3, is practiced in the construction of civil and industrial facilities, for the construction of foundations for different loads, the construction of concreted areas, sidewalks and routes, the production of monolithic reinforced concrete structural elements. Aggregate - granite or gravel crushed stone 5-20 mm + 20-40 mm.

M-300 concrete

Heavy concrete, intensively practiced in individual construction because of the combination of reasonable cost and solid technical properties. It is used for the construction of a blind area, foundations, the construction of monolithic low-rise buildings, the construction of flights of stairs and floors, the production of pillars. The grain size of the crushed stone of this concrete is a mixture of 2-3 fractions in the range from 5 to 40 millimeters.

M-350 concrete

Heavy-duty concrete for the creation of critical structural elements designed for significant loads. After the material gains strength, it becomes immune to external influences. Concrete of this brand is used to create walls, floor slabs, the foundation of a house, support columns, and airfield slabs. For this mixture, the grain size of granite crushed stone is a combination of grains of 2-3 sizes from 5 to 70 millimeters.

M-400 concrete

Refers to heavy concrete with a high content of Portland cement, which guarantees its highest characteristics of compressive strength, tensile, fracture. It is practiced for the construction of critical structures, such as road infrastructure facilities (bridges, overpasses), special structures (hydroelectric power plant buildings, dams, spillways, drainage and water outlets, tunnels, etc.), load-bearing structural elements, monolithic high-rise buildings. For such a mixture, granite crushed stone is practiced - a combination of various fractions of 5-25 millimeters + 20-70 millimeters.

M-500 concrete

Concrete of this class and above is produced by special order for the creation of extremely important structural elements. This is an expensive material with a high content of Portland cement, a large aggregate is crushed stone of dense rocks - serpentinite, amphibolite, granite with a fraction of 5-25 millimeters + 20-70 millimeters.

What happens if you choose the wrong one?

An illiterately selected grain size of a given building material can lead to the manufacture of a low-quality reinforced concrete product.

It is forbidden to use crushed stone with an identical fraction, since this can form empty spaces in the concrete, which reduces its stability and quality.

When adding gravel, you must adhere to the proportions. If there is too much of it, it does not adhere tightly to the cement, and the structure quickly collapses under the action of loads. The shortage leads to subsidence and a decrease in the strength of concrete.

The optimal volume is 80% of the total volume of the mixture.

To ensure the high quality of building materials, the fraction of crushed stone for concrete must comply with the conditions of GOST. Additionally, other parameters of a certain natural material are provided - they fluctuate based on the place of extraction. The manufacturer sets the parameters for each batch of crushed stone, and the consumer must compare and select the characteristics according to the tasks.

It is impossible to give an answer to the question of what grain size of crushed stone is best for the mixture.

In any particular episode, the choice depends on which brand of building material you need to get.

The comment was sent successfully.