Description of crushed stone screening and area of its use

In modern construction, natural stone is used quite often. This material is found almost everywhere in various spheres of human life, as it is capable of performing many functions. Crushed stone screening is in great demand at the present time. It is characterized by low cost, small particle size and good performance.

What it is?

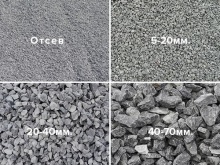

Crushed stone screening is a product obtained after crushing stones of natural or artificial origin. The raw material for it is usually granite, gravel or limestone. Each of the listed stones looks differently, respectively, it differs in some characteristics. Crushed stone is obtained by explosion and mechanical crushing, after which the final product must have 2 chipped edges or more.

Residues after performing this procedure are considered elimination. Judging by the description, the differences in screening from classic crushed stone are non-standard sizes, as well as the presence of small and dusty particles.

The difference between the above-described natural materials is that crushed stone with dimensions less than 0.5 cm is sent to screening.

Crushed stone screening looks like coarse sand. It costs much less than standard crushed stone, so it is more profitable to use it during construction. With the help of this type of material, you can significantly reduce construction costs, while not saving on the quality of the structure. There are practically no negative characteristics in the dropout of crushed stone as a building element in its category.

Product advantages:

-

fine particle size, thanks to which screenings can replace sand;

-

affordable cost;

-

a high level of interaction with other substances;

-

versatility of use.

Specifications

The scope of application of sifted crushed stone is directly influenced by the quality features of materials that are unique for each of the varieties. The main characteristics of the material include the following:

-

the ability to withstand significant loads and mechanical stress;

-

sizes;

-

the weight;

-

bulk density;

-

resistance to low temperatures;

-

flakiness - the presence in the total mass of grain with needle and flat forms;

-

volume of impurities;

-

radioactivity.

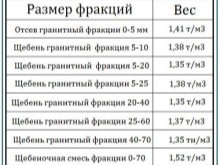

Screening of crushed stone can be presented in several fractions, in connection with this parameter, 1 cube of material weighs in different ways:

|

Crushed stone fraction, mm |

Weight, kg |

|

0-5 |

1410 |

|

5-10 |

1380 |

|

5-20 |

1350 |

|

5-25 |

1380 |

|

20-40 |

1350 |

|

25-60 |

1370 |

|

40-70 |

1350 |

|

Crushed stone mixture 0-70 |

1520 |

Species overview

Crushed stone fine screening has different components, therefore it is presented in a wide variety of species. Each type of dropout product applies to different categories of human life.

Granite

After crushing the gravel, material is obtained with dimensions from 0.1 to 5 mm. The bulk density of the dropout is considered to be 1330 kg / m3. The appearance of the crushing product has some resemblance to sand, while it does not contain clay elements, dust and organic substances. In screening out granite, the percentage of needle grain should not be more than 15%. This material is fairly easy to tamp and stack.

Screening of crushed stone of this type has high strength, it shows resistance to low temperature indicators and is considered environmentally friendly. Such a product is widely used in construction, road repair, and landscape design.

This material has a high cost, which is fully paid off by its good physical and chemical characteristics.

Gravel

Granite and gravel have some external similarities, since inorganic rocks are involved in their formation. But at the same time, crushed stone from gravel has special properties, due to which it is used in a narrow direction. Mineral inclusions are present in this friable product, which is the result of the destruction of hard rocks. Gravel is not highly durable.

In gravel crumbs, the grains have a size of 0.16-2.5 mm. The strength of the material determines its brand - M800-M1000. In this screening, dust and organic elements account for 0.6%.

The gravel product is actively used during the restoration of the roadway, the production of slabs, and the decoration of sites.

Lime

When sifting crushed limestone, a building material is obtained, which has a grain size of 2 to 5 mm. This type of dropout is characterized by the ability to dissolve in liquid. A cubic meter of such a product has a mass of 1300 kg, its strength grade is M400-M800. In crushed limestone, the amount of impurities is no more than 2% of the total mass.

The crumb is often used as an additive to animal feed and plant fertilizers. In addition, screening of this type is often included in the composition of the cement mixture from which the facing slabs are made.

Often this material is used for sprinkling roads during icy conditions.

Secondary rubble

Screening of secondary crushed stone is obtained during the disposal of concrete structures. The latter are usually destroyed or dismantled by man. Thanks to the special crushing technology, the rational use of construction waste is observed. Such use of recycled rubble allows significant savings during construction.

In this type of screening, the size of the granules usually varies from 0.1 to 10 mm. The material is often used as a filler in cement mortar or as a backfill for paving slabs. Crushed raw materials have also found their application in the process of assembling access roads and car yards.

Of all the listed types of crushed stone screening, granite is considered the most expensive, and limestone is the cheapest.

The cost of the material is influenced by the place of extraction and its method.

Spheres and features of application

To reduce overall costs during concrete mortar procedures, some builders are promoting the use of crushed stone screening. During the manufacture of the mixture for the arrangement of the foundation, a mixture of screening and cement is used instead of the main building component. When laying the strip foundation, it is worth observing the proportions so that the blocks of the future structure are fixed qualitatively. If you want to get the best result, you should use a sieve, and also mix it repeatedly. Some craftsmen practice replacing gravel with screening, as a result of which a new durable substance is obtained.

Concrete, which is made on the basis of crushed stone screening, has proven itself well during the arrangement of floors, columnar foundations. Such a substance is characterized by plasticity, pliability, therefore, it is simple and convenient to work with it. The blocks of this product have high performance characteristics, they are easy to use and store.

The use of such material does not imply the need for special skills and knowledge; even beginners in the field of construction will be able to use blocks from the dropout.

Screening is a fairly common building material, its demand is explained by its low cost. This by-product has a lot of advantageous characteristics, thanks to which it is actively used in the following areas:

-

in the construction of private, municipal and large types;

-

in the production of building materials such as concrete and cinder blocks;

-

as a material for the absorption of a water filter at stations where waste water is processed;

-

as a free-flowing substance capable of combating road icing;

-

in landscape design.

Currently, screenings from natural crushed stone are used quite often.

This material not only helps to reduce the cost of the building process, but also maintains high quality characteristics of the structure.

The comment was sent successfully.