Varieties of crushed stone and areas of its use

It is difficult to single out the type of construction work where crushed stone would not be used - this is a truly irreplaceable material, offered in all the variety of colors and shapes. Each type of work requires a material of this or that density, flakiness level, adhesion and fractionation parameters. This and much more will be discussed in our review.

What it is?

Crushed stone is one of the most popular building materials. Nowadays, no construction process is complete without it. It is in demand when building a solid foundation for mixing concrete. All types of crushed stone are used when filling highways and arranging access roads.

In a word, it is a versatile building material with a wide range of uses.

Crushed stone is obtained by crushing rocks. The extraction of the rock itself is carried out in open pit mines with the help of special loaders. The resulting raw materials are transported to production shops, where they are sorted and sent to mechanical crushing units. The smallest grains are filtered for screening, and the rest of the material is sorted depending on the base and additional fractions. The crushing technology used determines the approximate parameters of the adhesion and flakiness of the crushed stone. To clarify the characteristics of the stone, after processing, it is sent to the laboratory, where the technical and operational properties and compliance with the requirements of GOST are empirically established. Each batch is labeled and receives a quality certificate. This is a very important stage, since only certain types of gravel are used for construction and installation work - those that meet the standards GOST 8267-93. Crushed stone is sold in bags of 10-50 kg, big-bags or in bulk in cars. Crushed stone can be white, yellow, pinkish or gray in color.

It can be washed or unwashed.

Comparison with gravel

Crushed stone is often confused with gravel. Both materials are obtained from rocks, however, the methods of obtaining them differ. So, gravel is formed in the course of natural destruction of parent rocks under the influence of natural processes - rain, wind and ultraviolet rays. This process is continuous and takes several millennia. Crushed stone is formed artificially by industrial crushing. The speed of obtaining these stones is much higher, it depends on the strength of the rock and the power of the crushing plants.

It can be argued that gravel has its own natural and historical past, while crushed stone does not.

Features of origin also determine differences in the appearance of materials. The grains of crushed stone obtained during crushing have angular edges and a rough surface. Gravel, especially river or sea gravel, has a rounded shape and smooth texture. Accordingly, crushed stone better than gravel provides adhesion to the cement mass, thanks to which the material is widely in demand when performing construction work. But the decorative qualities of crushed stone are much lower than that of gravel.

The latter is mainly used in landscape design for the compilation of rockeries and the design of garden paths.

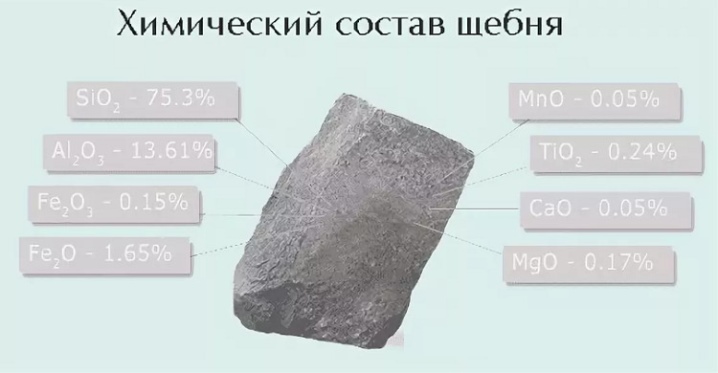

From the point of view of the chemical composition, crushed stone and gravel can have similar components, but they can also differ - this directly depends on the initial type of raw material. For example, materials with an identical composition are obtained from a rock mass. What if crushed stone is made from waste of construction or metallurgical production, the composition will differ from gravel.

Main characteristics and properties

Depending on the characteristics of the parent rock and manufacturing techniques, crushed stone may have different technical parameters. When choosing one or another bulk material, it is imperative to take into account its operational parameters, on which the overall quality of the work performed directly depends.

In accordance with the requirements of GOST, several basic criteria for the quality of construction crushed stone are distinguished.

Density

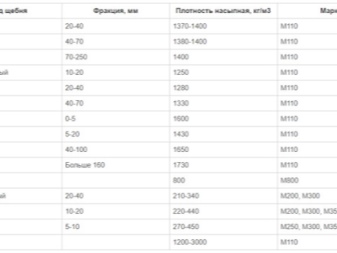

This parameter depends on the characteristics of the origin of the material and ranges from 1.2 to 3 g / cm3. The higher the density of gravel, the more versatile the building material is.

Its strength is directly related to the density of crushed stone, the relationship between these characteristics is directly proportional. Strength is understood as the ability of grains to withstand mechanical loads of varying intensity. This parameter is determined on the basis of a series of experiments in which stones are compressed under pressure in a cylinder - such tests simulate the real conditions of using bulk material. Depending on the results, crushed stone is assigned one of the strength groups from M200 to M1600, while the digital indicator reflects the maximum permissible load that the material can withstand.

Each class of crushed stone has its own characteristics and industry of use.

- M200 - low strength. Such a stone is used when creating a road with low traffic or arranging drainage systems.

- М300-М600 - low strength. It is in demand in the same industries as the M200 crushed stone.

- М600-М800 - medium strength. The stone is in demand when erecting lightly loaded structures, for example, curtain walls of a house.

- М800-М1200 - sufficient strength. This crushed stone is considered universal, it is used for the construction of supports, fences, pouring foundations and bearing supports.

- М1200-М1400 - increased strength. The stone has found application in the construction of foundations for high-rise buildings, hydraulic structures and bridge supports.

- М1400-М1600 is a heavy-duty stone. The application is limited to the installation of particularly critical objects.

The presence of impurities

Any stone usually contains admixtures of weaker rocks. They are subject to mandatory rationing, since the strength of the bulk material depends on their volume. The proportion of such components is calculated in experimental laboratories by applying a pressure of 20 MPa to the material.

In accordance with the current regulations, the maximum concentrations of additives for low-grade inclusions have been established:

-

М1600 - no more than 1%;

-

М1000-М1400 - not more than 5%;

-

М400-М800 - no more than 10%.

If the share of fragile additives exceeds 20%, then such crushed stone is referred to as gravel. It is used exclusively when filling low-intensity tracks and erecting temporary structures.

Flakiness

This is one of the main properties of crushed stone. The parameter reflects the presence of acicular and lamellar grains in the total mass of crushed stone. Depending on the flakiness value, the bulk material is different:

-

normal - 25-35%;

-

improved - 15-25%;

-

cuboid - no more than 15%.

Crushed stone with low flakiness is widely demanded in construction and installation works, where it is important to compact the cement mixture as much as possible. Needle grains will form voids, and more stone will have to be added, but even in this case, the density of the finished product will be lower when pressed.

Crushed stone with a high content of needle and flat elements is more often in demand when filling the roadway.

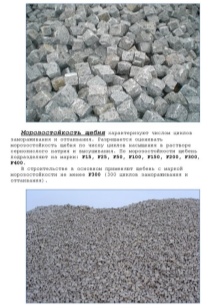

Frost resistance

This indicator is especially important in the conditions of the Russian climate. This criterion reflects the number of freezing and subsequent thawing cycles that the stone will withstand without losing its strength characteristics. The value of the parameter under experimental conditions is calculated by drying and subsequent saturation of the stone in a concentrated solution of sodium sulfate.

When marking, frost resistance is displayed in the Latin letter F, followed by numerical data - they show the number of freezing and thawing cycles.

Frost resistance of crushed stone is in the range of F15-F400:

-

F15-F50 - unstable material, optimal for drainage systems and interior work in warm buildings;

-

F50-F150 - a stable stone, suitable for the construction of low-rise structures in warm areas;

-

F200 is a type of crushed stone with high stability, optimal for the installation of complex buildings in the conditions of central Russia and northern regions.

Adhesion

An important parameter is the adhesion of crushed stone - the ability of a stone to adhere to concrete components with different cement ratios. The larger the parameter, the better the quality of the material.

As practice shows, the best adhesion is distinguished by gray and dark gray stone.

Bulk density

This indicator is calculated when transporting crushed stone, as well as when using it in filling. The parameter reflects the weight of the stone, which will fit in one cube. Depending on the parameters of the grains, this value varies: the finer the crushed stone, the more it will fit in one unit of volume. The numerical indicator is calculated in kg per m3. So, the bulk density of granite material is 1400 kg / m3, and limestone - 1250 kg / m3.

Radiation background

Some types of crushed stone become a source of radiation, so each batch must undergo compulsory certification, as well as have the appropriate documents confirming its quality. The radioactive background of the granite stone is maximal; in total, several groups of crushed stone radiation activity are distinguished.

-

First class - not higher than 370 Bq / kg. It is used in all types of construction and installation work.

-

Second class - more than 370 Bq / kg. Optimal for the construction of industrial facilities and roadways. Not recommended for interior decoration.

-

Third class - over 750 Bq / kg. Allowed for use in construction far from residential buildings and places of residence of people.

Species overview

The mineral composition of crushed stone directly depends on the composition of rocks. So, granite and basalt varieties are of magmatic origin, dolomite - sedimentary, marble crushed stone has all the signs of metamorphic rocks. Depending on the origin, several types of gravel are distinguished. Let us dwell on the most demanded in the territory of our country.

Granite

Granite crushed stone is obtained by crushing the granite massif. It is characterized by uneven edges. Grinding dimension varies from 5 to 120 mm.

Granite crushed stone is the most durable, it is considered universal. In addition to granite, it can include impurities of mica, quartz, and feldspar. Depending on the presence of these crystals, the grain hue can be pinkish, gray, even reddish. The strength parameter of the granite stone corresponds to the M1400-M1600 brands, the frost resistance is F300-F400, the flakiness is lowered. At the same time, granite material can often have an increased radiation background, so it should not be used when working in residential buildings and in the arrangement of adjacent lands.

When purchasing such a stone, it is imperative to require a quality certificate for the batch.

Gravel

Crushed gravel is formed during screening of rocks or by blasting during quarrying. Crushed gravel has a grayish color, the parameters of the grains vary from fine to large fraction.Compared to granite, such a stone is less durable - the strongest grade corresponds to M1200. This crushed stone is significantly inferior to granite in terms of such important criteria as external decorativeness. Nevertheless, it has its advantages.

The extraction of gravel crushed stone requires less labor and financial costs, since the rock parent rocks, in comparison with granite rocks, are much less durable. This means that less powerful equipment is needed to crush them. Gravel is a ubiquitous building material, this provides an affordable price for the crushed stone obtained from it. Gravel has zero background radiation. This important advantage provides an increased demand for the material in the installation of residential buildings, social and medical facilities.

Crushed gravel is produced in several sizes: 3-10 mm, 5-20 mm, as well as 5-40 mm and 20-40 mm.

Limestone

Limestone is produced from dolomite. It is in demand in the construction of lightly loaded structures. Limestone has a high crushing capacity, it is mined in industrial quarries. Crushed stone is obtained during the splitting of rocks, the material is 95% calcium carbonate.

Crushed stone has become ubiquitous due to its democratic cost. However, the strength of the stone is low, and the water absorption is high. This significantly limits the directions of its application. Compared to granite and gravel bulk material, crushed limestone is in demand when creating pavements of low intensity. In addition, the material found distribution in the manufacture of fertilizers, as well as soda and lime. Carbonate crushed stone is sold in three sizes: 5-20 mm, 20-40 mm, and 40-70 mm.

Secondary

Nowadays, secondary stone is widespread. It is obtained by crushing waste from the construction industry: monolithic foam glass structures or reinforced concrete products. The production cost of such crushed stone is low, and accordingly, the price of the finished product is affordable. In comparison with granite, this type of crushed stone will be 2-3 times cheaper. However, such a cost indicates the lowered parameters of frost resistance and density of the building material. The density grade of secondary crushed stone corresponds to M800, and frost resistance is kept at F150.

Such crushed stone is in demand in the field of strengthening soft soils, can be used as a filler for sand-cement mortar and in the arrangement of local routes.

Slag

Crushed slag is the result of crushing waste from the steel industry. This material has an increased density - it is higher than that of granite stone. However, this density causes an increase in the mass of the material; in construction, this is considered a significant disadvantage.

Crushed slag has increased water absorption parameters, therefore, structures using this bulk component should not come into contact with water. The frost resistance of crushed slag is low; it can withstand only 15 freezing and subsequent thawing cycles. For reference: granite can withstand 250-300 cycles. The use of slag materials in the construction business is advisable only taking into account its shortcomings.

It is in demand in road improvement and housing construction.

Shale crushed stone is a little less common - it is mined from rocks of the volcanic type. Visually, it looks like a dense mound of flattened stones, the colors can be green, yellowish, brown or burgundy. Slate is popular in the production of building materials and the construction of low-rise structures. There is a rock of shale, the crushing of which forms a large number of thin plates - they are in demand in the manufacture of roofing materials. Shale crushed stone is also used to create monolithic reinforced concrete structures. But it is most widely used in landscape design.Slate stone is used to decorate summer cottages, decorate decorative areas in the local area.

Quartz crushed stone is obtained from quartz-based rocks - its density corresponds to that of granite. However, at the same time, quartz gives a weak radioactive background and is characterized by an extremely attractive appearance. It is used mainly in garden decor.

Less often in the construction industry, diorite stone is used. It is mined from plagioclase with a high content of colored minerals. Supplied in fine grain size 5-20 mm.

Fractions

Speaking about what grounds exist for the classification of crushed stone, one should dwell on its fractional separation. Depending on the characteristics of the feedstock and the capacity of the crushing plants, the stone can be produced in several standard sizes.

5-20

Such crushed stone is used mainly in the production of small-sized products, for example, paving slabs.

20-40

This material is in demand when creating monolithic forms, for example, well rings. Crushed stone of this fraction is used in the production of all types of concrete.

40-70

The coarse fraction is relevant for the creation of large forms and the production of concrete in large volumes. Such crushed stone is in demand in the preparation of the arrangement of highways and the construction of large industrial facilities. To increase the thickness of the layer when arranging the roadway, a two-layer pillow is usually arranged: a large stone is poured from below, from above - a middle one.

70-150

Fractions of granite crushed stone 70-120, 120-150, as well as 150-300 can also be called but. This stone is used mainly for decorative purposes - when installing hedges and fences.

The material is in demand in land reclamation and the creation of reinforced concrete structures.

Spheres and features of application

Crushed stone is in demand in a wide variety of industries.

So, in the construction business, it acts in the form of a filler of sand-cement mortar... Depending on the proportions of the components, it can be used in the construction of the foundation, for butting fence posts and decorating the subfloor screed. The material is used for arranging the crushed stone base of the roadway.

In country gardening, crushed stone is in demand when decorating paths in the country, compacting the substrate between the beds. Depending on the size of the fraction, it can be used when forming foundations before asphalting roads and installing paving slabs. In landscape gardening, mainly crushed stone of the middle fraction is used: when using a small stone, the consumption of material per square meter will be higher.

But for the construction of a playground, the crushed stone-sand mixture is not suitable because of the high risk of injury to the child when falling.

In the industrial sphere, crushed stone is used to create reinforced concrete and concrete products... Such material is used in enterprises engaged in the manufacture of concrete of various brands.

The comment was sent successfully.