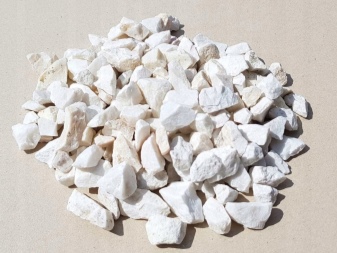

Features of white rubble

The features of white crushed stone must be known to everyone who wants to decorate their site and perform other work. On the market there are decorative crushed stone 5-20 mm and 40 mm, large and small white stones in bags and other options. People, of course, are not indifferent to what it is made of and where this material is used.

What are they made of?

All such products are of a purely inorganic origin. To get white crushed stone, crush:

- boulders;

- various rocks;

- gravel;

- overburden and enclosing rocks of various deposits;

- substandard waste from the metallurgical industry.

Of course, the colors of the stone are very different. Sometimes only sorting helps to separate them. But in any case, the initial stage is the explosion. Only in rare cases is the primary crushing of the rock carried out with the help of powerful earth-moving and mining equipment. Then the breed is collected, transported to an industrial site. There it is processed on special crushing machines.

What happens?

White crushed stone is most often obtained on the basis of:

- granite;

- dolomite;

- limestone.

Dolomite and limestone mass is in demand mainly in lightly loaded building structures. Responsible work involves the use of a denser and more stable material. The chemical composition of such a stone is dominated by calcium carbonate.

Because the breed is widespread, it is widely sold and relatively inexpensive.

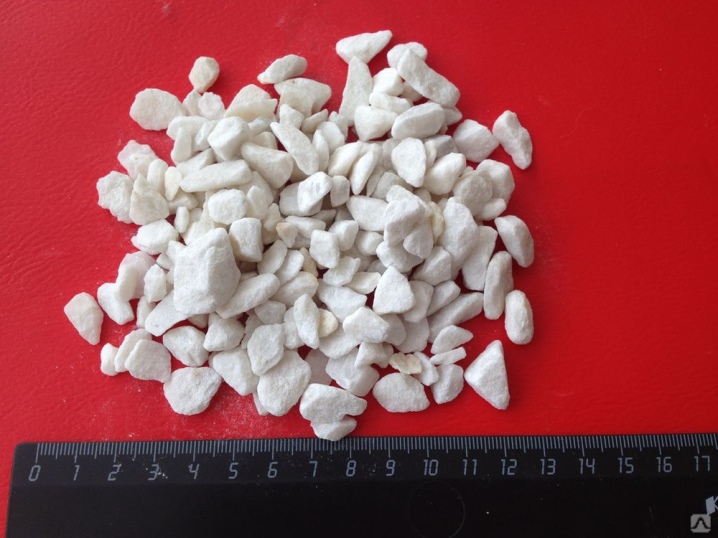

Along with the chemical composition and mineralogical characteristics of decorative stones, their size range (fraction) also plays a very important role. The scope of application of a particular batch of material largely depends on it.

- Crushed stone ranging in size from 5 to 20 mm belongs to the small category. Basically, this breed is needed for the monolithic construction of residential and non-residential buildings.

- Stone ranging in size from 20 to 40 mm is also widely in demand among builders. They use it to produce ordinary concrete and various reinforced concrete structures.

- Strictly speaking, material up to 5 mm in cross section cannot even be called full-fledged crushed stone. Its use, if possible, is very limited.

- Sometimes they supply large (from 40 to 70 mm) and the largest (over 70, up to 300 mm) stone. Both options are needed in the most demanding jobs. They are often used where very high mechanical stress is generated.

Note that the method of movement also plays an important role. Usually, crushed stone is transported and unloaded in bulk. But sometimes it is sent in bags. Such material has strictly specified, usually agreed upon in advance:

- coloring (including shades);

- factional affiliation;

- the degree of flakiness.

The advantages of bag delivery are also:

- the ability to "close" a relatively small order, when complex volumetric work is not required;

- strictly measured and predetermined mass (which makes it possible to make a predictable load on transport, on loaders and builders);

- the presence of markings (which is important for distinguishing a stone belonging to a certain category);

- careful observance of state standards and technical conditions;

- the ability to order exactly as much material as you need, without overpaying for excess and without wasting time on delivery;

- the ability, thanks to dense packaging, to use a variety of types of transport and reduce the loss of transported cargo to a minimum.

Of course, you will have to pay extra for the packaging.But in most cases, these are quite justified costs. Crushed stone is usually delivered in bulk only to large construction sites. For the most demanding decorative work, as a rule, they take not ordinary construction, but tumbling crushed stone.

It is specially brought to aesthetic perfection using special technological techniques.

Where is it used?

The use of crushed stone, as already mentioned, is dictated mainly by the faction to which it belongs. So, the smallest part of this breed (up to 5 mm) is mainly applicable in the decorative finish of the tracks. It is very difficult to use it elsewhere, and it is not particularly advisable. The most widespread use all over the world has a crushed stone fraction of 5-20 mm. She is needed:

- in the manufacture of reinforced concrete blocks;

- when creating foundations;

- when arranging roads - both internal, on the territory of the organization, and in general use;

- for the preparation of concrete in private construction and repair.

Stone with a cross section of 20-40 mm is also often bought and delivered to various objects. This material is suitable for:

- drainage works;

- preparation of tracks for trams and trains;

- formation of foundations for industrial and large public buildings, high-rise buildings.

Crushed stone with a cross section of 40-70 mm is also used in the drainage. It can also be taken for making concrete. We are talking about concrete intended for especially loaded sites and objects. The largest category (over 70 mm), like the smallest, has a limited area of use.

It can be used for framing swimming pools, for decorating natural reservoirs and arranging fences.

The comment was sent successfully.