How to choose façade slabs?

Regardless of what material the building was built from, it needs protection from adverse climatic conditions. To perform this function, facade slabs are excellent, with which you can sheathe it. In addition to reliable protection, they enhance the appearance of the building - making it stylish and modern.

Material features

Facade slabs are intended for exterior cladding of a house. They are individual elements of various sizes and shapes. They can be fastened to tile adhesive, as well as using the ventilated facade principle. The slabs have a decorative function, as they can be made in the form of brick, stone or plaster.

Facade slabs can improve the thermal insulation of a room if a heater is placed under them. They have a soundproofing function. In addition, the elements are durable and protect the structure from moisture penetration, are resistant to the spread of mold and mildew, and become an obstacle for rodents and insects.

Plates are fireproof, do not lose their properties during significant temperature fluctuations, and also have a long service life. They do not require special care - some options require simple cleaning with rainwater. They are also easily repaired, it is possible to replace individual elements without disassembling the structure.

Among the shortcomings, one can note the rather large weight of some types of material. Due to this, it cannot be installed on weak-bearing structures - installation difficulties may arise.

Also, the surface on which the panels are laid must be leveled - this is necessary if you plan to use glue as a fastening material.

Varieties and sizes

Facade slabs can be classified according to the following criteria:

- material of manufacture;

- the method of painting the panels;

- form of products.

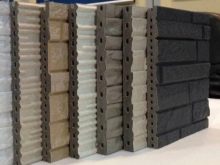

In terms of shape, the panels are rectangular (small in width) and quite long, square and modular. The staining method is responsible for the final visual result. The panels can imitate natural stone, brick, wood and tiles. The slabs contain natural substances and synthetic additives, which can be clay, wood, metal, glass, concrete or polyurethane.

According to the material of manufacture, the following types of facade panels are distinguished.

- Ceramic facade slabs. This type of slab is made from clay. They are environmentally friendly and fireproof, perfectly retain heat, have water-repellent and sound-proof functions. They tolerate temperature changes well, are ideal for creating sandwich panels, and at the same time have a rather large weight.

- Polypropylene plates. Such slabs can be used for facade and basement works. They are very durable and have a long service life, they tolerate negative external influences well. The material is lightweight, which makes it easy to install. Does not require special care.

Of the minuses, the fragility of the panels, the lack of thermal insulation properties can be noted. Also, polypropylene plates cannot be combined with other finishing materials.

- Fiberglass plates. It is based on durable tempered glass.These slabs perfectly withstand the effects of wind and other climatic phenomena, provided they are correctly installed. When using this type of material, it must be borne in mind that if improperly designed, the structure can pose a potential threat to human health. At the same time, fiberglass panels transmit light well, are resistant to mechanical stress and solar radiation, have water-repellent properties and have a long service life.

- Thermoplastic boards. Due to the presence of polyurethane in the composition, the boards have excellent thermal insulation properties. They are lightweight - they can be installed both on new houses and used for cladding old buildings. Durable and reliable material has excellent performance and does not require special maintenance.

- Fiber cement boards. A material based on cement and quartz sand, it contains special lightening additives. During the production process, they need to be coated with ceramics or polymers for a more aesthetic appearance of the panels. Fiber cement boards have a large number of colors and a variety of textures in their palette. They have excellent sound insulation, do not create problems during operation. The elements are covered with an antistatic coating.

- Wooden slabs. The panels are made of wood, and during the production process they are treated with water-repellent and antiseptic compounds. Due to this, the service life of the material is significantly extended. To increase the strength, the wood is pressed. The material is environmentally friendly and lightweight. Excellent for sound insulation and heat preservation in the room, resistant to temperature extremes.

Of the negative points, it can be noted that wood panels burn well, are able to absorb moisture - this negatively affects the surface. The material has a fairly high price.

- Metal plates. These panels are based on sheets of aluminum and galvanized steel. The outer side has a polymer coating, which makes the material resistant to corrosion processes. However, if damaged, there is a risk of rust formation. The boards are fireproof, do not absorb moisture, and are very durable. In addition, despite their considerable weight, they are easy to install and the panels can last for a long time. They can withstand severe temperature fluctuations and do not require specific maintenance. Among the disadvantages can be noted insufficient resistance to external mechanical stress. For example, if the slab is deformed, it will no longer be possible to return it to its previous shape. In the summertime, the room may not be very comfortable due to the ability of metal plates to heat up strongly in the sun.

- Cement particle boards. Plates made of this material are distinguished by the absence of load on the walls. DSP can be used as formwork, as they are not subject to deformation.

- OSB boards. These panels are composed of softwood chips. They are environmentally friendly and highly durable. The composition contains wax, due to which the material perfectly repels moisture, is resistant to adverse climatic conditions.

- Basalt slabs. This material consists of compressed mineral fibers bonded with a special glue. The use of basalt slabs is absolutely safe - they can be used when working with any premises, including children's and social ones. Plates are lightweight, fireproof, have excellent sound insulation and thermal insulation properties. They are resistant to mechanical stress and moisture. The panels can be easily mounted on different types of surfaces, without requiring them to be aligned. Among the disadvantages are installation using special glue and a rather high price for the material.

- Composite boards. The use of this type of stove is becoming more and more popular among consumers. They have a wide palette that allows you to bring to life the most original design solutions.

Slabs can be made of galvanized steel, aluminum, granite, fiber cement and metal with the addition of stone chips. They do not delaminate and have an excellent anti-corrosion effect.

Design

There are many options for decorating buildings. However, with the help of facade slabs, it becomes possible to completely change the appearance of the house, making it original, modern and unique. Materials are presented in a wide range, which allows you to come up with various finishing solutions.

Facade slabs for brick, plaster or stone can effectively transform the structure with minimal time and effort. Naturally, the work will cost significantly less than finishing with natural material.

Often consumers choose terracotta clay tiles to create unusual designs. The color depends on the rocks of the clay contained in the composition, and can vary from beige to dark brown.

Manufacturers overview

On the modern market there are plates of both domestic and foreign manufacturers. Experts recommend giving preference to trusted firms that have confirmed their brand with numerous positive customer reviews.

Consumers note the good quality of the facade panels produced by the companies Alta-profil, Fineber, Wandestein, Vinylit and other well-known companies. In addition, it should not be forgotten that excellent performance cannot be expected from a material that is too low in price. Therefore, it is recommended to study all the nuances and plan a purchase based on a set of necessary characteristics, visual appeal and product price.

How to choose?

Before buying facade slabs, you need to pay attention to such parameters as the strength of the product, ease of installation, weight, which will not create unnecessary stress on the structure of the frame room. You also need to take into account the environmental friendliness and non-toxicity of materials. They must be resistant to aggressive external influences, the appearance of fungus and mold, serious temperature changes.

An important point is the price of the product. The ideal option would be to purchase products that combine acceptable cost, desired appearance and the required set of properties and functions.

Design options

Despite the fact that facade slabs are divided into many types, their installation for the most part has many identical moments. They have a device on the principle of ventilated facades, although various elements can be used for fastening. First, you need to install a grid of profiles, on which the slabs themselves will be attached.

In the process of finishing, if necessary, you can do the insulation and soundproofing of the room. Since the facade is ventilated, condensation does not form in it, which helps to avoid many unpleasant problems during operation.

When using facade panels for cladding a building from the outside, you can use a special adhesive. However, it is appropriate to use it not with all types of material and not on all types of buildings.

Recommendations for work

Facade panels must be installed from bottom to top. For their docking, a groove and a ridge are used, and fixation is done using self-tapping screws.

Since the cladding has not only a decorative, but also a protective function, it is not recommended to save too much on it. It should be borne in mind that, in addition to purchasing plates, additional financial costs will be required when purchasing fasteners. They must be painted in the same color scheme as the plates.

The material should not be chosen based only on your preferences in appearance. It is worth examining the performance characteristics of the product.

Experts do not recommend doing the installation of facade tiles with your own hands in the absence of experience in such work - it is better to contact professionals who will not make mistakes in installation, and also explain the necessary operating requirements, and then a correctly laid surface will delight the consumer for many years.

Beautiful examples in the exterior

The design of the facades of the house when decorating with facing plates can be varied. Vivid and beautiful examples of works are attached in the photographs.

The facade cladding used slabs for brick and plaster. According to the designer's idea, the lower part is made in darker colors, and the border between the slabs of different types runs at the same level where the border between the floors is.

Fiber cement facade panels are used for the design. They are resistant to dirt, do not require special maintenance and can be cleaned with normal rain.

This photo shows the hinged ventilated facade of the building. The cladding is made using fiber cement boards.

Shown here are porcelain stoneware façade tiles. It is made like a stone, giving the building an elegant and expensive appearance.

See the following video for the installation process of the polyfacade.

The comment was sent successfully.