All About Refractory Sheets

Heating equipment requires careful maintenance and proper installation. For this, there are a large number of building materials prepared for use in high temperature conditions. These elements include refractory sheets, which will be discussed.

Peculiarities

First of all, it is very important to list the main features of refractory sheets, which can help both in the choice of material and in its installation.

- Fireproof. Since in baths, saunas and places where stoves and heating equipment are located, the heating power can reach 300-400 degrees, it is very important to install especially stable sheets. There are several types of them, but they all have one feature - protection of the environment from high temperature heating. This minimizes the risk of fire and other situations that are prevented by compliance with safety requirements.

- Resistance to environmental conditions. Since most boards and their varieties are made of chemicals, they are protected from the effects of alkalis, acids and other elements that deform the surface of conventional materials. In addition, manufacturers create raw materials that prevent mold and mildew and are resistant to dirt. This feature makes the maintenance of refractory sheets easier and less costly.

- Strength. The chemical compounds that serve as the basis for the cladding of high-temperature equipment are quite dense and meet the requirements for the required strength in relation to different installation methods. Some types of slabs have high rates of resistance to physical damage, which makes them more reliable and durable.

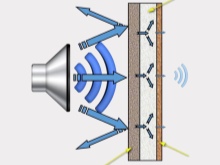

- Soundproofing. A feature of not all, but only some types of refractory materials. As a rule, soundproofing materials have a dense, filled inner structure, due to which this effect is achieved. This choice is preferable for those who deal with noisy heating equipment, the operation of which may be inconvenient.

Views

The most famous and until recently widespread sheet material that can withstand high temperatures was steel. When sanded to a high gloss, it reflects heat and prevents heat from reaching walls and floors where there is a heat source. It is worth saying that steel can be used for the installation of various types of equipment for a bath, a gas boiler and stoves.

Asbestos boards are also known and widely used in various areas of heating equipment installation.

This material is very easy to install for cladding and does not require special costs. Among the advantages, one can note high thermal insulation properties, which are expressed in use at temperatures up to 500 degrees.

As a rule, these boards are based on chrysolite asbestos, which provides mechanical strength and resistance to various chemicals.

Then there are basalt slabs, which are a universal solution for owners of powerful heating equipment. In addition to excellent heat dissipation properties, this material has good sound insulation. This feature has become available due to the quality of raw materials, which is considered not only easy to use, but also environmentally friendly. It is worth noting that basalt slabs can withstand high temperatures up to 900 degrees, and are also resistant to the effects of various substances.Of course, this material is more expensive than most others, but this cost is due to the convenience of installing the plates and the presence of sound insulation.

GVL, aka gypsum fiber sheet, is a raw material, in which fiberglass predominates. It is resistant to physical impact, and also has high thermal insulation properties. Other advantages include ease of installation and operation, as well as a large number of mounting options for other materials. GVL is known for the fact that after its use it leaves little waste, which is very convenient for processing and application in cladding.

LSU or glass-magnesium sheet is an analogue of GVL, distinguished by its special structure. The composition of this material includes a large number of chemical compounds, for example, magnesium oxide, perlite, magnesium chloride, as well as various composite materials.

The presence of these components not only seals the inner part of the LSU, but also gives it unique fire-retardant properties, which are higher than that of all other materials.

In addition, glass-magnesium raw materials are resistant to moisture, so they do not lose their key properties after being under water for several hours.

LSU is durable, lightweight, will prevent the formation of fungus, mold and bacteria. This material has been poorly tested in the domestic market, since the country of origin is China. Nevertheless, it is recommended to use GVL and other types of plates, which are fully studied and classified, which makes them safer and more understandable for the consumer.

Vermiculite panels are used primarily because of their decorative component. If you want to make the cladding while maintaining an attractive appearance, then this material will suit you best. The main component for fastening is heat-resistant mastic, which significantly improves the refractory range up to +1200 degrees. The structure itself is a dense panel, differing in texture and top layer. It is worth noting that vermiculite panels are available in different variations, so their choice depends on which option you like externally.

Applications

Refractory sheets are most often used for cladding heating equipment, for example, boilers and stoves in a bath or sauna. The main reason for the demand is the fact that the equipment can be close to the walls. So that the high temperature does not affect them, installation in the form of cladding and the creation of protective screens is required. They cover the entire space from which heat can be spread. These processes have their own characteristics and differ in the technological sequence, but most of the plates are installed in a similar way.

In this case, the structural cladding depends on specific conditions, for example, the location of the furnace / boiler, their dimensions, as well as the material of the room itself.

In addition to private and domestic use, fire-resistant sheets are used in production and industrial areas. Some areas that contain explosives of any kind need to be safe and protected. It is these materials that prevent the spread of fire in cases of fuel ignition.

Some building structures are completely made of low-fire resistant plastic and its derivatives, so the nearest space is sometimes sheathed with fireproof sheets. And also rooms with a large number of communications, for example, server stations, are lined with protective plates that prevent the transfer of fire from one type of equipment to another.

Do not forget about fireplaces. This decor element also needs proper installation and operation.

At the same time, vermiculite boards with a decorative component can be used in the decoration of premises that are more demanding in terms of protection from high temperatures.

Today, there are many similar materials on the domestic market, so their choice depends on certain properties and advantages that the sheets are endowed with.

The comment was sent successfully.