All about expanded clay concrete blocks

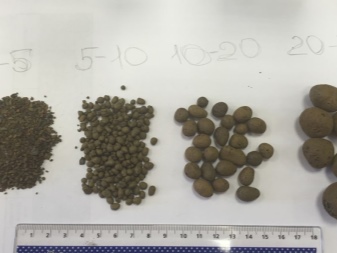

Expanded clay concrete blocks are a building material, in the production of which cement, sand, water are used. Expanded clay gravel is also added to the solution with a total mass of up to 60%, with a size of 5 to 10 mm. The larger the fraction, the lower the strength of the finished products and their weight. Expanded clay concrete wall blocks are manufactured in accordance with GOST 33126-2014. They come in different types and are used for different purposes.

Advantages and disadvantages

The main advantage of expanded clay blocks is environmental friendliness. In their manufacture, no harmful chemical components are used, which makes them safe for the construction of residential premises and public buildings.

There are other benefits as well.

- Excellent thermal insulation properties. Blocks made from quality raw materials in compliance with the technological process perfectly retain heat inside the room. Due to this feature, they can be used in the construction of buildings operated in a harsh climate.

- Long service life. The blocks are capable of retaining their original properties and performance characteristics for 70 years.

- Good noise insulation qualities, provided by voids inside the product.

- Refractoriness. Blocks do not burn when exposed to open flames. When heated, they do not emit toxic substances into the atmosphere.

- Strength. In contrast to aerated concrete, expanded clay blocks are much stronger. Thanks to this, they do not require reinforcement with a reinforced concrete "belt".

- High adhesion, achieved through a rough surface.

- Water vapor permeability. Expanded clay concrete products, as well as natural wood, can "breathe", due to which a favorable microclimate is created in the room.

- Resistance to damage by harmful microorganisms, the formation of mold and mildew.

- Resistance to all kinds of weathering. The material is not afraid of direct sunlight, precipitation, frost, sudden temperature changes.

In contrast to gas silicate blocks, expanded clay are cheaper. In addition, due to the lightness of the material, there is no need to incur additional financial costs for the construction of a massive foundation.

The material is large in comparison with brick (1 block by volume can replace 7 clay bars). Thanks to this feature, the speed and simplicity of masonry are significantly increased.

Expanded clay blocks are not an ideal building material. He, like everyone else, has some disadvantages. The disadvantages include fragility, due to which the products do not tolerate shock and dynamic loads poorly. When processing, cutting or sawing building material, chips, cracks and other defects are easily formed on it.

The disadvantages include unpresentable appearance of wall blocks, which is why the structure erected from them requires additional external and internal finishing with decorative materials.

How are blocks made?

The material is manufactured in specialized factories. The technological process of production at each enterprise is different. For example, different companies use different proportions of raw materials, some manufacturers provide for the presence of plasticizing additives in the formulation to improve the properties of products. In large factories, blocks are manufactured on conveyor equipment.

Smaller enterprises use stationary lines - they are less productive, but they are also cheaper. For self-production of products, a concrete mixer, molds and a vibropress are used.

Hand-made production includes several stages.

- Preparation of raw materials. To make 100 kg of mortar according to the classical recipe, 54.4 kg of expanded clay, 27.2 kg of sand base, 9.21 kg of cement and 9.09 kg of water are required. With an increase in the amount of cement, the block will acquire additional strength, but this will increase its weight and deteriorate thermal insulation. To prepare the solution, it is necessary to put the components in the concrete mixer in a strict sequence: first, liquid is poured, then expanded clay and cement, sand - last. All components are mixed in a concrete mixer for at least 2 minutes.

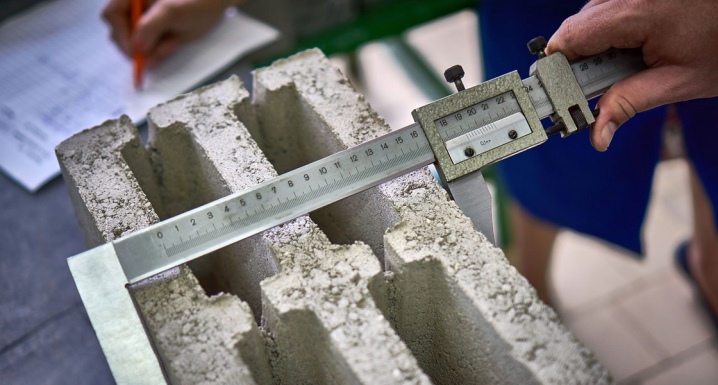

- Filling with a mixture of forms. In order for the dried block to come out easily, the inside of the forms must be greased with used oil. They are installed on a vibrating table and filled evenly with the mixture using a shovel. To compact the solution, you need to periodically turn on the vibrator - the vibrations will contribute to the uniform distribution of the concrete mass.

- Drying of blocks. The forms with the solution must stand for 24 hours, after which the blocks must be pulled out and laid out, providing a distance between them of 2-3 cm. Products in this form must be dried within 28 days, after this time they will acquire optimal branded strength.

The production of expanded clay concrete blocks at the plant is carried out according to the same principle. The difference lies in the automated process. At enterprises, special autoclaves are used for the final drying of products. In such chambers, due to the high temperature, the drying time is reduced from 28 days to 12 hours.

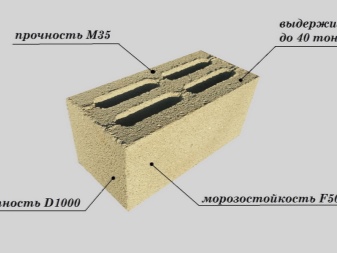

Properties

Some of the most important technical characteristics are strength and density. The first parameter affects the bearing capacity of the walls, the second - on heat conservation and sound insulation. The block density varies over a wide range. The value ranges from 500 to 1800 kg / m3. It directly depends on the size of the expanded clay used: the smaller the fraction, the higher the density. The minimum value of the strength of the material is 35 kg / cm2, the maximum is 250 kg / cm2.

Heat transfer is directly related to the density of the blocks. For example, for products with a density of 500 kg / m3, the heat transfer will be no more than 0.24 W / mC, and with a density of 1800 kg / m3 - 0.81-0.90 W / mC.

According to GOST, lightweight aggregate concrete block materials are produced with several classes of frost resistance:

- F 25;

- F 35;

- F 50;

- F 75.

The numbers in the marking indicate the number of freezing and thawing cycles of the block completely saturated with liquid (without loss of technical parameters and performance).

All types of expanded clay concrete products have high fire resistance - their fire safety class is A1. This means that the blocks are able to withstand exposure to an open flame for 8 hours without collapsing.

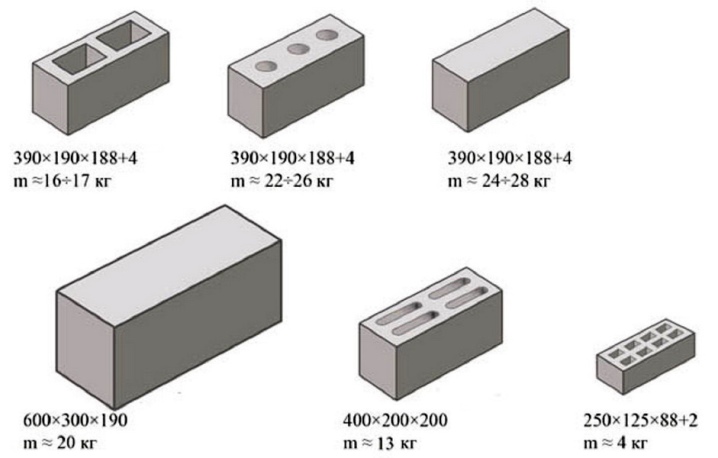

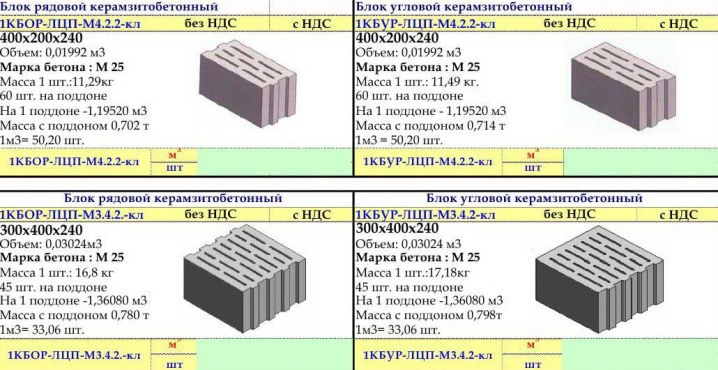

Species overview

Manufacturers produce several types of expanded clay blocks. Depending on the filling level, they are divided into solid, hollow and slotted. In the case of corpulent, the presence of internal air cavities is not provided. If we compare them with hollow ones, then they are distinguished by greater weight and better bearing capacity. Due to this feature, solid blocks are most often used for the construction of structures, which will be subjected to a large load in the future.

Hollow products have through (ventilation) or partial air cavities... Thanks to such voids, the building material has less weight and reduced thermal conductivity. Cavities are rectangular or cylindrical. Ventilation products have square air cavities.

Hollow blocks are cheaper than solid blocks.

Slotted products have a different number of longitudinally or transversely located through slots (from 6 to 13). The most popular is the six-slot block. It is designed for the construction of external walls. Slotted building materials will cost more than hollow ones.

Blocks are also classified by function. They are wall, partition or facing. Each species has its own characteristics.

Wall

Designed for the construction of external load-bearing structures. Wall solutions are both full-bodied and with air voids. The standard dimensions of such products are 400x200x200 mm. Large block sizes allow you to quickly erect a wall and reduce the consumption of cement working mortar.

Partition

Most often they are used for the construction of internal structures that do not perform a load-bearing function. Unlike the former, they have a lower mass, lower bearing capacity. Products are manufactured in sizes 400x200x200 mm, and manufacturers also offer non-standard solutions.

Facing

Cladding blocks appeared on the market not so long ago and have not yet had time to gain massive popularity. Their main features:

- wide range of color palette;

- a dense and smooth surface without roughness, cavities and other external defects (there are also products on sale that are decorated with the relief of natural stone);

- correct geometry.

Colored blocks can be used for external cladding of buildings, when erecting fences and garden curbs.

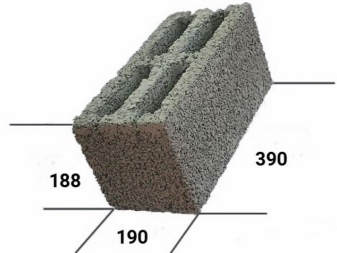

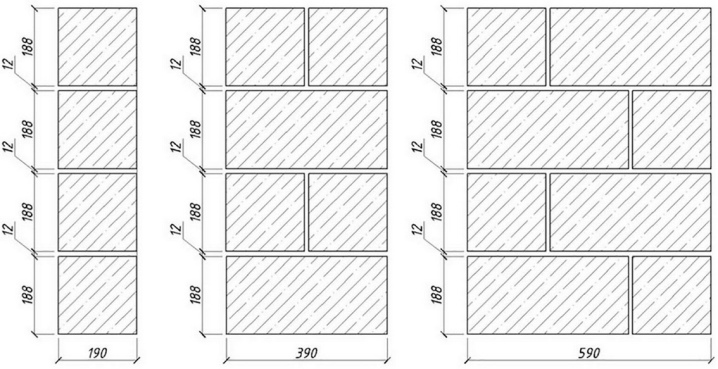

Dimensions and weight

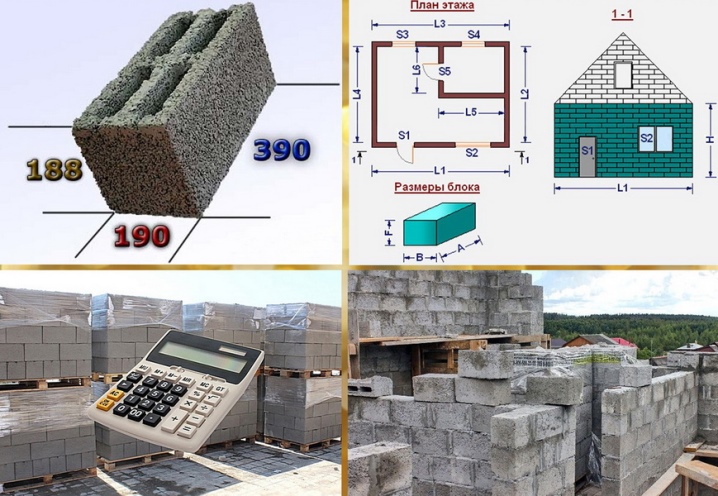

The most popular dimensions of solid blocks for masonry walls are 390x190x188 mm. When operating such products (with a standard wall thickness of 400 mm), it is possible to erect structures in 1 block. Manufacturers also manufacture small and large block materials. Their dimensions are dictated by TU. Popular sizes:

- 190x188x390 mm;

- 200x100x200 mm;

- 390x290x188 mm;

- 390x90x188 mm;

- 390x80x188 mm;

- 288x190x188 mm.

There are also products of 300x200x200 mm on sale. According to the regulations of GOST 6133-99, modules may have small deviations in size. Discrepancies for width and length - ± 3 mm, height - ± 4 mm, wall thickness - ± 3 mm. Manufacturers are also often involved in custom-made blocks. For example, it can be modules with dimensions of 400x400x200 mm.

The mass of products depends on many factors: the size of the modules, the coefficient of voidness, the composition of the initial solution (the less expanded clay was used in the production, the greater the weight of the finished products). The minimum weight of standard blocks is 8 kg, the maximum is 22 kg. Large-sized corpulent modules have a greater weight.

Manufacturers

Many domestic factories are engaged in the production of various types of expanded clay blocks. Let's list the most popular ones.

- Kstovo expanded clay concrete plant. Produces modules using expanded clay fraction of 5-10 mm. The material is manufactured on the Rifey-Polyus automated line. The company is engaged in the production of solid and four-slot blocks.

- "Teplostroy IM". The company was founded in Cheboksary. Has been producing lightweight aggregate concrete modules since 2005. The productivity is 1500 blocks per day. For the production of building materials, the company buys expanded clay 10-20 mm, which is further crushed into smaller fractions - 5-7 mm.

- Ishleyskiy plant of building materials. One of the first producers of expanded clay blocks in Chuvashia. The company was founded in 2000. In the first years of operation, the modules were made using homemade equipment. Today the automatic line "Rifey-Universal" is used for their production. The daily productivity of the plant is 1200 items.

- Bloks 21. The company is engaged in the manufacture of hollow clay blocks in Novocheboksarsk. The maximum productivity reaches 1500 items per day. Bloks 21 offers its customers its own delivery and unloading.

- EcoBlock. Large format block manufacturer. The plant is located on the territory of Naberezhnye Chelny. Offers modules of non-standard sizes, as well as decorative solutions for cladding work. The company is engaged in the manufacture of blocks without sand. Expanded clay, cement and water are used to prepare the solution.

Popular manufacturers of block expanded clay materials also include the companies "AlyansStroy", "PF Veles", "GK Mercury", "Forward".

Areas of use in construction

Expanded clay blocks have been used in the construction industry around the world for several decades. Using such material, you can significantly save on construction costs.

Various building elements and structures are erected from expanded clay blocks.

- Foundation. For this, the most durable full-bodied modules are used - they are able to withstand heavy loads. The foundation will stand for a long time, since the blocks do not shrink and are not afraid of groundwater.

- Base / plinth. This is the “foot” of the structure, which lies on the foundation.

- Bearing walls, partitions and ceilings. They are widely used in low-rise construction in the construction of buildings of no more than 3 floors.

- Baths. In order for a building exposed to high temperatures and humidity to stand for a long time, it is important to provide for its good waterproofing and insulation.

- Garages, cellars and cellars.

- Gazebos, verandas and terraces, various annexes to a residential building or cottage. Both open and closed structures are erected from expanded clay blocks.

- Fences. Such structures are often erected from several building materials, for example, expanded clay modules, wood, wrought iron elements. With the right approach to the design, the fences will look original.

Every year, non-standard use of expanded clay blocks is more and more common. Garden benches are erected from them - they often become an original and inexpensive solution for the improvement of a place for recreation. From expanded clay modules, you can build a porch, staircase, well.

Blocks with large voids are also used to make flower beds. - they will bring elegance and brightness to the space. For a more colorful design, the blocks can be painted in the desired colors.

Quantity calculation

Do-it-yourself construction of a house, basement, country house or other structures is a troublesome and financially costly event. To save the budget, you need to prepare an estimate in advance and calculate the required number of blocks.

Thanks to the correct calculations, it is possible to reduce the risks of spending money on the purchase of excess material.

To calculate the required number of blocks, you need to take measurements. Algorithm of actions:

- calculating the perimeter of the structure (the easiest way is to calculate the sum of all sides of the rectangle);

- the resulting value must be divided by the length of 1 module - this way the number of blocks required to build 1 row is determined;

- to calculate the total number of rows, divide the height of the building by the height of the block;

- to find out the required number of blocks, you need to multiply the values obtained in points 2 and 3.

In this case, it is not worth taking a stock of building materials, since the calculations did not take into account the presence of window and door openings. You can also use online calculators to calculate the number of blocks.

Since the blocks are stored on pallets, you also need to calculate how many are on the pallet. The number will depend on the area of the pallet, on the weight of the building material and its dimensions. For example, if 60 expanded clay blocks are stacked on a pallet, you need to divide the required number of blocks by this value.

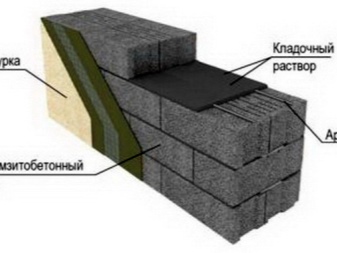

Masonry mix

The masonry mortar must have certain properties that will give the structure erected from blocks the required strength. For this, the proportions must be strictly observed in the manufacture of the mixture. It is recommended to use an electric or manual concrete mixer to prepare the mortar. If it is not there, suitable containers with the required volume will do.

You should not mix a lot of solution at a time - the amount must be calculated so that it is enough for 2 hours of work.

To make an adhesive mass you will need:

- cement (grade not lower than M 400);

- sand (it is best to take river sand);

- water.

Recommended ratio of sand, cement and water – 3: 1: 0.7, respectively. If necessary, the volume of water can be increased or decreased - the change in one direction or the other depends on the initial moisture content of the sand. To prepare the solution, you first need to mix the dry components, then add liquid in parts. The consistency should resemble thick sour cream.

Based on the average calculations, it can be concluded that for 1 m3 of blocks, 0.2 m3 of independently prepared cement slurry will be required. Ready-made mixtures are also on sale. Various additives are added to them, thanks to which the finished mass acquires greater plasticity. On average, to complete 1 m2 of masonry, about 30 kg of the finished mixture will be required. Ready-made formulations are easy to use. Their main disadvantage, in comparison with a self-prepared solution, is their higher cost.

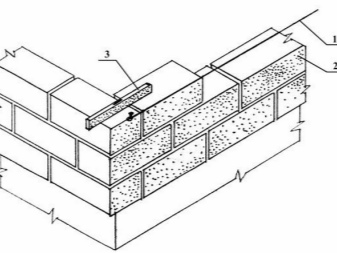

Masonry scheme

There are several variations of the masonry of expanded clay concrete blocks. The choice depends on the climatic characteristics, the desired wall thickness and the personal preferences of the developer.

To properly lay 1 row, you need to apply a waterproofing shell to the foundation. You need to start work from the corners. To do this, a solution is placed on the plots with a layer of up to 3 cm. Having installed the modules in 4 corners, they are pressed. A building level is used to check the correct position. Further, along the corner sections, you need to pull the twine - along its line, 1 row of modules will be laid.

We list the popular masonry schemes.

- Half a block. With this method, the block must be laid along the base along the length (in this case, the wall thickness will be equal to the width of 1 module). This scheme is most often resorted to when erecting household buildings.

- 1 block wide. This is the most common method. Unlike 1 scheme, in a square meter of such masonry, approximately 2 times more blocks will be involved. This method is used in the construction of residential buildings and garages. In this case, the wall thickness will be equal to the length of 1 expanded clay block. As a result, you get a more durable, reliable and warm structure, for which it is not necessary to provide additional insulation.

- Well masonry. It is characterized by the construction of 2 walls from expanded clay modules: internal and external. There are voids between them, intended for their subsequent filling with insulation material.

When laying out the final row, it is recommended to reinforce with a monolithic layer of concrete or make a reinforced belt. It will help to evenly distribute the load from the roof over the walls.

Review overview

For the construction of residential private houses, cottages or outbuildings, expanded clay blocks are used more and more often. Builders note the following advantages of this building material:

- low price;

- fast construction time due to the large size of the blocks;

- low weight, due to which the masonry can be made independently without the involvement of special equipment;

- obtaining durable masonry that can withstand serious loads;

- the ability to make a cheap finish using plaster.

Some builders attributed to the disadvantages of modules the formation of "cold bridges" during masonry, the emergence of difficulties when sawing off blocks. Judging by some reviews, in order to create an optimal microclimate in housing in cold weather, additional insulation will have to be provided.

The comment was sent successfully.